Sulfide solid electrolyte and preparation method and application thereof

A solid electrolyte, sulfide technology, applied in solid electrolytes, composite electrolytes, non-aqueous electrolytes, etc., can solve problems such as no battery electrochemical performance, and achieve good air stability, good ionic conductivity, and low synthesis cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

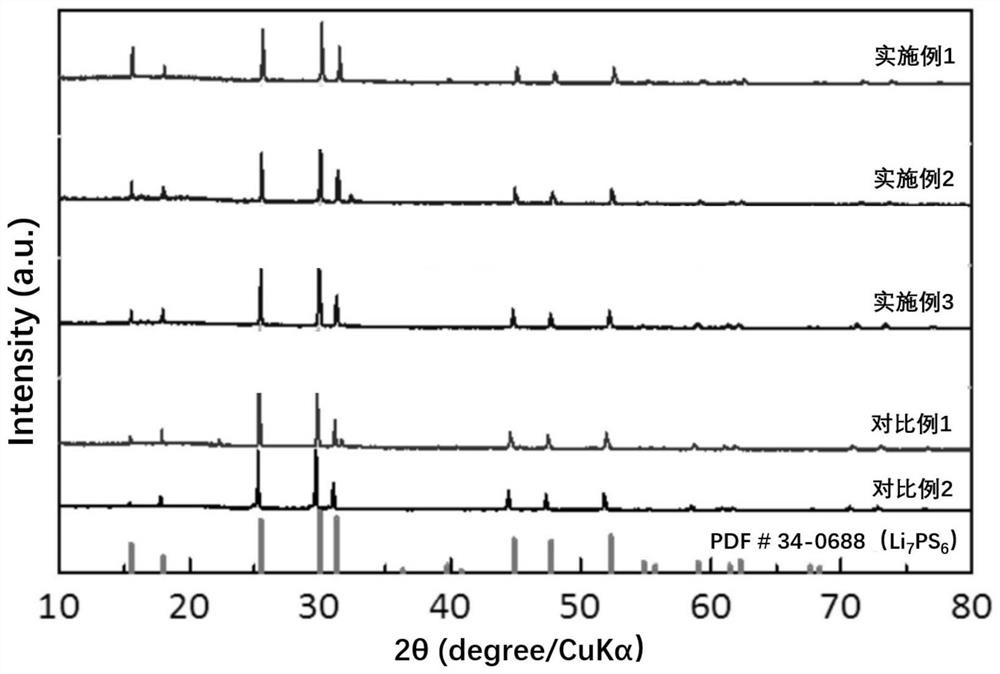

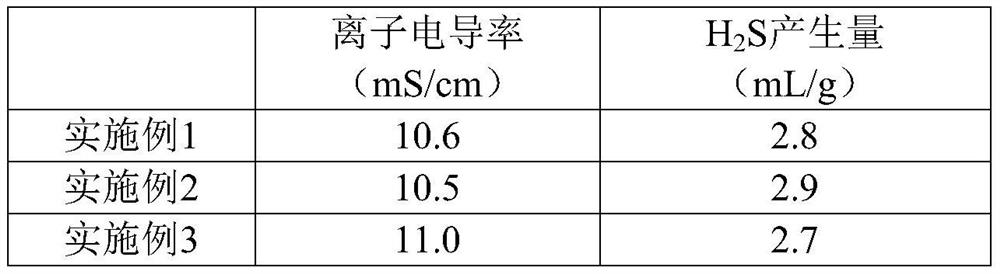

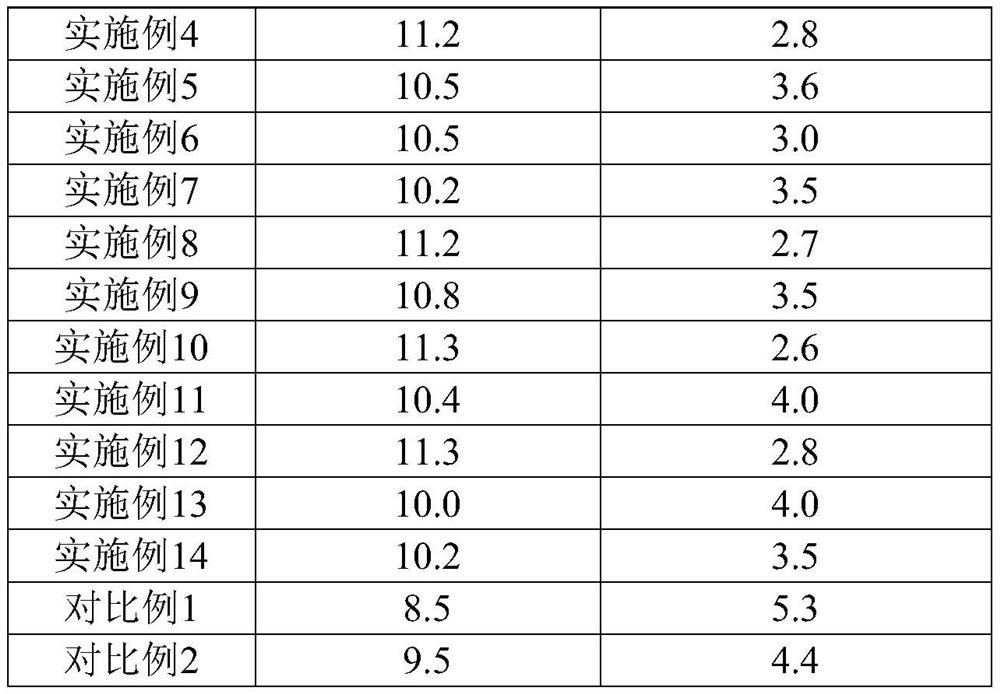

Embodiment 1

[0040] This embodiment provides a preparation method of a sulfide solid electrolyte, the preparation method is as follows:

[0041] (1) Under the protection of an argon atmosphere, according to the ratio of the substance molar ratio of 4.5:1:1:0.5:2, weigh Li with a purity of more than 99%. 2 S, P 2 S 5 , metal Li powder, sulfur and LiCl are mixed, then the above-mentioned raw materials are ball milled under the condition of moisture content below 10ppm, the rotating speed of the ball mill is 350rpm, and the time of the ball mill is 15.0h, wherein the ball-to-material ratio of the ball mill is 35:1, obtaining Primary powder material.

[0042] (2) The powder raw material obtained in step (1) is pressed into tablets by a tablet press to obtain a sheet-like raw material, and the sheet-shaped raw material is loaded into a sintering mold for sintering, wherein the temperature is raised to 550°C, the sintering time is 4.0h, and then cooled to room temperature with the furnace, ta...

Embodiment 2

[0044] This embodiment provides a preparation method of a sulfide solid electrolyte, the preparation method is as follows:

[0045] (1) Under the protection of an argon atmosphere, weigh Li with a purity of more than 99% according to the ratio of the substance molar ratio of 4.5:1:1.02:0.5:2 2 S, P 2 S 5 , metal Li powder, sulfur and LiCl are mixed, then the above-mentioned raw materials are ball milled under the condition of moisture content below 10ppm, the rotating speed of the ball mill is 350rpm, and the time of the ball mill is 15.0h, wherein the ball-to-material ratio of the ball mill is 35:1, obtaining Primary powder material.

[0046] (2) The powder raw material obtained in step (1) is pressed into tablets by a tablet press to obtain a sheet-like raw material, and the sheet-shaped raw material is loaded into a sintering mold for sintering, wherein the temperature is raised to 550°C, the sintering time is 4.0h, and then cooled to room temperature with the furnace, t...

Embodiment 3

[0048] This embodiment provides a preparation method of a sulfide solid electrolyte, the preparation method is as follows:

[0049] (1) Under the protection of an argon atmosphere, weigh Li with a purity of more than 99% according to the ratio of the substance molar ratio of 4.5:1:1.02:0.5:1:1 2 S, P 2 S 5 , metal Li powder, sulfur, LiCl and LiBr are mixed, and then the above raw materials are ball milled under the condition of water content below 10ppm, the rotating speed of the ball mill is 350rpm, the time of the ball mill is 15.0h, and the ball-to-material ratio of the ball mill is 35:1 , to obtain the first powder material.

[0050] (2) The powder raw material obtained in step (1) is pressed into tablets by a tablet press to obtain a sheet-like raw material, and the sheet-shaped raw material is loaded into a sintering mold for sintering, wherein the temperature is raised to 550°C, the sintering time is 4.0h, and then cooled to room temperature with the furnace, take ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com