Method for preparing LATP solid electrolyte with blocking electrode in one step at low temperature

A solid electrolyte and blocking electrode technology, which is applied in the manufacture of electrolytes, non-aqueous electrolyte batteries, and electrolyte batteries, etc., can solve problems such as silver particle shedding, slurry conductivity decline, plasma instability, etc., and achieve the idea of expanding research, Improving machinability and accelerating the effect of material development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Inorganic oxide electrolyte Li of 0.3 g particle size is 600 nm 1.3 Al 0.3 Ti 1.7 (Po 4 ) 3 Put the mortar, then drip 60 μl of concentration of 1 mol / L of tetrafluoroborate in the mortar, fast grinding uniform, first put a layer of purity 99.9% thickness 0.2 μm gold foil in the cold burning mold, ground The powder is poured into the mold and then placed in a gold foil, and the cold is warmed to 140 ° C and pressurized under 500 mPa for 60 minutes to obtain Li with a gold foil surface. 1.3 Al 0.3 Ti 1.7 (Po 4 ) 3 Solid state electrolyte.

Embodiment 2

[0024] Inorganic oxide electrolyte Li of 0.3 g particle size is 600 nm 1.3 Al 0.3 Ti 1.7 (Po 4 ) 3 Put the mortar, then add 60 μl of a concentration of 1 mol / L in the mortar. After the body poured into the mold, then put it in a layer of gold foil, and the cold burning was 10 ° C / min to 200 ° C and pressurized under 500 mPa for 60 minutes to obtain Li with a gold foil surface. 1.3 Al 0.3 Ti 1.7 (Po 4 ) 3 Solid state electrolyte.

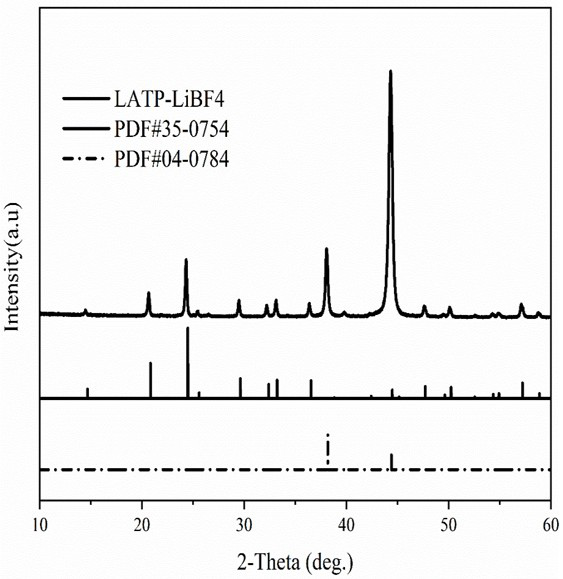

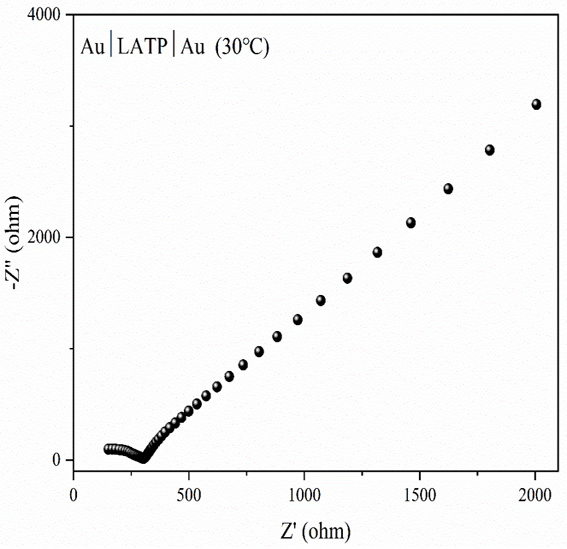

[0025] figure 1 , figure 2 It is a physical map and an XRD diagram of 1 mol / L tetrafluoroborate as a solution of titanium phosphate aluminum lithium aluminum solid electrolyte, using this manner to obtain a ceramic sheet having a gold foil with a gold foil, and the XRD diagram shows that no new substance is produced. image 3 , Figure 4 It is an impedance map and an electron microscopic map of 1 mol / L acetic acid solution, and an electron microscope, a medium-high frequency zone that intersects the real shaft, no hopping point in the medium and h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com