Black talc-based antibacterial agent as well as preparation method and application thereof

An antibacterial agent, talc-based technology, applied in the field of black talc-based antibacterial agent and its preparation, can solve the problems of high manufacturing cost, complicated manufacturing process and curing process of antibacterial coating, reduce production cost, realize high-value utilization, Antibacterial effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment prepares activated black talc Talc-7

[0045] Sieve the raw ore of Guangfeng black talc, the fineness is required to be 200 mesh, and the underscreen is temporarily called black talc. Weigh 5g of black talc, calcinate it in a muffle furnace at 700°C for 2h, lower the temperature slowly, and take it out from the muffle furnace after the color changes from black to off-white. Calcined in air atmosphere, the initial temperature is 20°C, the heating time is 68min, the holding time is 2h, and the cooling time is 150min. Labeled Talc-7.

Embodiment 2

[0047] This embodiment prepares activated black talc Talc-9

[0048] Sieve the black talc raw ore, the fineness is required to be 200 mesh, and the underscreen is tentatively called black talc. Weigh 5g of black talc, calcinate it in a muffle furnace at 900°C for 2h, lower the temperature slowly, and take it out from the muffle furnace after the color changes from black to off-white. Calcined in an air atmosphere, the initial temperature is 20°C, the heating time is 88min, the holding time is 2h, and the cooling time is 200min. Labeled Talc-9.

[0049] The calcination temperature in Examples 1 and 2 was changed, and activated black talc was prepared by calcination at different temperatures.

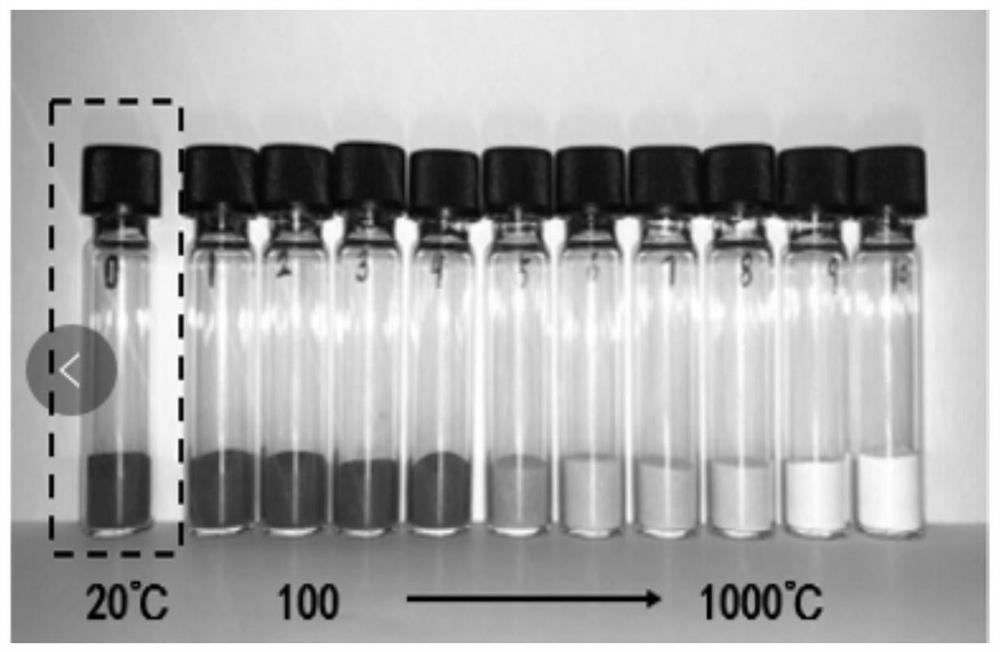

[0050] figure 1 Calcining black talc at different temperatures (100°C-1000°C), it can be seen that the whiteness of black talc is significantly improved, of which black talc appears gray at 500°C-800°C, and white at 900°C-1000°C.

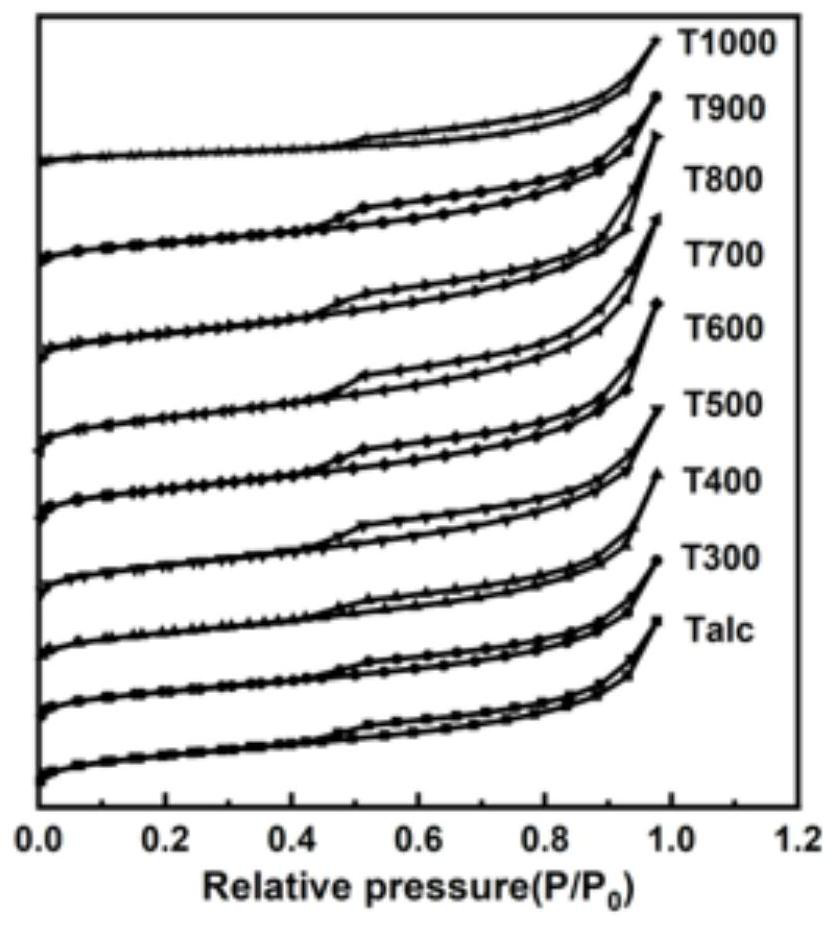

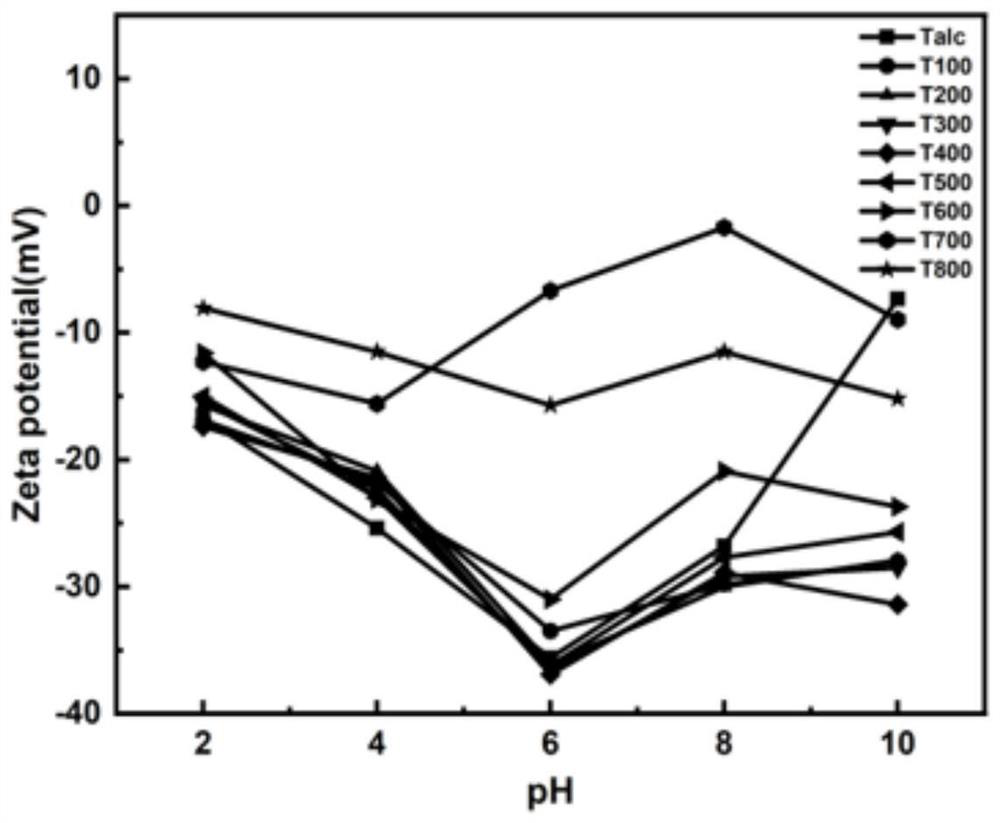

[0051] Such as figure 2 As shown, as the temperatur...

Embodiment 3

[0054] This embodiment prepares black talc antibacterial material 5%ZnO / Talc-7

[0055] Weigh 0.14g Talc-7, 0.1785g Zn(NO 3 ) 2 ·6H 2O, added to 90ml of ethanol, stirred ultrasonically at room temperature for 20 minutes to form a uniform and stable suspension, and heated the suspension to 75°C. Weigh 0.12g of granular NaOH, add it into 45ml of ethanol, and stir ultrasonically for 15min at room temperature to form a clear solution. The NaOH solution was added dropwise to the suspension for 60 min. After the dropwise addition, the solution continued to stir for 60 min, and was centrifugally filtered, and the filter cake was washed three times with water to remove surface residual Zn(NO 3 ) 2 ·6H 2 O and NaOH, placed in an oven at 60°C for 12 hours to obtain Zn(OH) 2 / Talc-7 composite material, further Zn(OH) 2 / Talc-7 composite material was calcined in a muffle furnace at 400°C for 4h, which was recorded as 5%ZnO / Talc-7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com