Preparation method and application of CeO2-xSx/CdZnS/ZnO nano material

A nano-material and hydrothermal reaction technology, applied in the field of catalytic chemistry, can solve the problems of greening photocatalysts and achieve the effects of enhanced utilization of visible light, low solubility, and good hydrogen evolution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

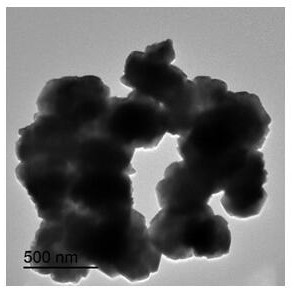

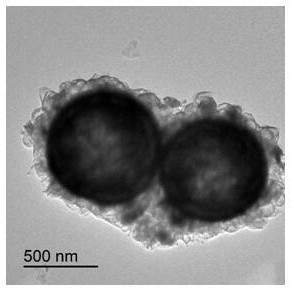

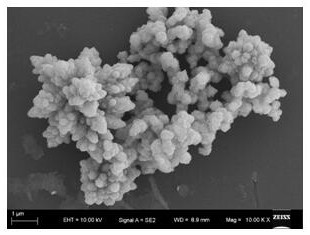

Image

Examples

preparation example Construction

[0032] CeO of the present invention 2-x S x The preparation method of / CdZnS / ZnO nanometer material comprises the steps:

[0033] (1) Add sodium citrate solution to urea solution to obtain a mixture of urea and sodium citrate;

[0034] (2) Add cerous chloride to the mixed solution obtained in step (1) and stir evenly, slowly add hydrogen peroxide, and stir;

[0035] (3) The mixed liquid obtained in step (2) is subjected to hydrothermal reaction, cooled after the reaction, centrifuged and cleaned, and dried to obtain CeO 2 ;

[0036] (4) CeO obtained in step (3) 2 Together with thiourea, put it into a tube furnace for calcination and vulcanization, and obtain a dark gray powder sample CeO 2-x S x .

[0037] (5) The sulfided sample CeO obtained in step (4) 2-x S x Ultrasonic with water to form a suspension, add cadmium nitrate, zinc nitrate and ethylenediamine to stir, the resulting mixture is subjected to hydrothermal reaction, cooled after the reaction, centrifuged an...

Embodiment 1

[0041] (1) Put 1.4g of urea in 180mL of ultrapure water for ultrasonic dispersion for 5min, add 90mL of 10mM / L sodium citrate solution, react for 10min under vigorous stirring, add 1.1g of cerium chloride, stir for 30min, then add 15mL / min Add 1.4mL hydrogen peroxide dropwise at a constant speed, and keep stirring for 30min. Add the light yellow mixed solution formed by the reaction into a 50mL polytetrafluoroethylene high-pressure hydrothermal reaction kettle, react at 180°C for 22h, and after natural cooling, centrifugally clean and dry at 70°C to obtain light yellow CeO 2 sample.

[0042] (2) Put the dried sample into the ark together with 8g of thiourea in a tube furnace for vulcanization to obtain CeO 2-x S x , keep the reaction at 500°C for 2h, and the heating program is 2°C / min.

[0043] (3) Take 0.5 mMCeO 2-x S x Place in 30 mL of deionized water to form a suspension with ultrasonic waves to disperse evenly, add 0.5 mM cadmium nitrate and 0.5 mM zinc nitrate, stir...

Embodiment 2

[0045] Change the MCeO in step (3) on the basis of embodiment 1 2-x S x , the ratio of cadmium nitrate and zinc nitrate, so that the molar ratio of the three is 1:8:8, that is, "take 0.5 mMCeO 2-x S x Place in 30 mL of deionized water to form a suspension with ultrasonic waves, make it evenly dispersed, add 4mM cadmium nitrate and 4mM zinc nitrate", and the rest are exactly the same as in Example 1 to obtain CeO 2-x S x / CdZnS / ZnO, referred to as CCZS-8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com