Environment-friendly flame-retardant material for plates and preparation method of environment-friendly flame-retardant material

A kind of flame retardant material, environmental protection technology, applied in the field of environmental protection flame retardant material and its preparation, can solve the problem that the flame retardant effect needs to be improved, achieve the effect of high performance and meet the promotion demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

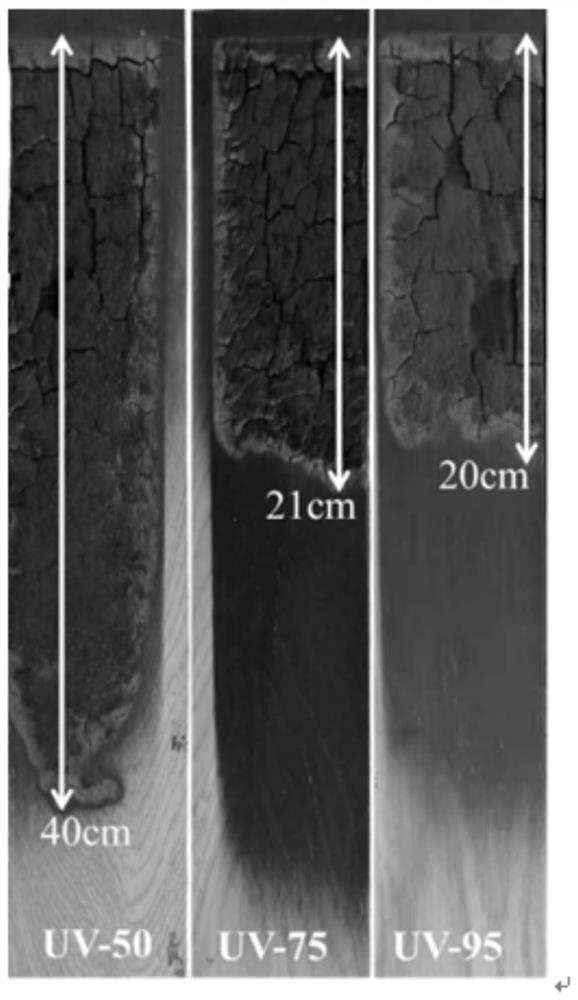

Image

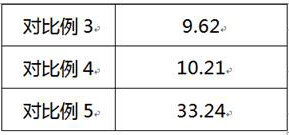

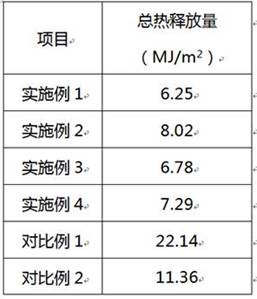

Examples

preparation example Construction

[0034] The preparation method of the environment-friendly flame-retardant material used for the board comprises the following steps:

[0035](1) Add polyurethane acrylic resin, epoxy acrylic resin, guanidinourea phosphate, pentaerythritol phosphate, and melamine urea-formaldehyde resin into water, microwave power is 100-180W, temperature is 40-45°C, and rotation speed is 200-400r / min Stir for 30-40min to prepare the mixture a;

[0036] (2) Add ethylene glycol to the mixture a prepared in step (1), and stir at a speed of 200-300r / min for 10-15min to prepare mixture b;

[0037] (3) Add desiccant, defoamer, dispersant, and filler to the mixture b prepared in step (2), and stir for 8-12 minutes at a rotating speed of 300-400r / min to prepare mixture c;

[0038] (4) Add a thickener to the mixture c prepared in step (3), and stir for 6-10 minutes at a rotation speed of 200-300 r / min to obtain an environmentally friendly flame-retardant material.

Embodiment 1

[0041] An environmentally friendly flame-retardant material for boards, the flame-retardant material includes the following components in parts by weight: 100 parts of polyurethane acrylic resin, 70 parts of epoxy acrylic resin, 18 parts of guanidinourea phosphate, and 12 parts of pentaerythritol phosphate 25 parts, 25 parts of melamine urea-formaldehyde resin, 35 parts of ethylene glycol, 25 parts of anhydrous calcium chloride, 22 parts of silicone defoamer, 15 parts of alkali metal phosphate dispersant, 1300 parts of heavy calcium carbonate, alkali swelling 18 parts of thickener, 110 parts of water.

[0042] The preparation method of the environment-friendly flame-retardant material used for the board comprises the following steps:

[0043] (1) Add polyurethane acrylic resin, epoxy acrylic resin, guanidinourea phosphate, pentaerythritol phosphate, and melamine urea-formaldehyde resin into water, and stir for 36 minutes at a microwave power of 150W, a temperature of 43°C, and...

Embodiment 2

[0048] An environmentally friendly flame-retardant material for boards, the flame-retardant material includes the following components in parts by weight: 90 parts of polyurethane acrylic resin, 80 parts of epoxy acrylic resin, 17 parts of guanidinourea phosphate, and 10 parts of pentaerythritol phosphate 26 parts of melamine urea-formaldehyde resin, 30 parts of ethylene glycol, 30 parts of anhydrous calcium sulfate, 20 parts of mineral oil defoamer, 20 parts of polycarboxylate dispersant, 1000 parts of barium sulfate, 15 parts of alkali swelling thickener part, 150 parts of water.

[0049] The preparation method of the environment-friendly flame-retardant material used for the board comprises the following steps:

[0050] (1) Add polyurethane acrylic resin, epoxy acrylic resin, guaninourea phosphate, pentaerythritol phosphate, and melamine urea-formaldehyde resin into water, and stir for 39 minutes at a microwave power of 100W, a temperature of 42°C, and a rotation speed of 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com