Hyperbranched organic ionic liquid type metal corrosion inhibitor and preparation method thereof

A metal corrosion inhibitor and organic ion technology, applied in the field of hyperbranched organic ionic liquid type metal corrosion inhibitor and its preparation, can solve the problems of complex process, destruction of the original system, limitation, etc. The effect of corrosion and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

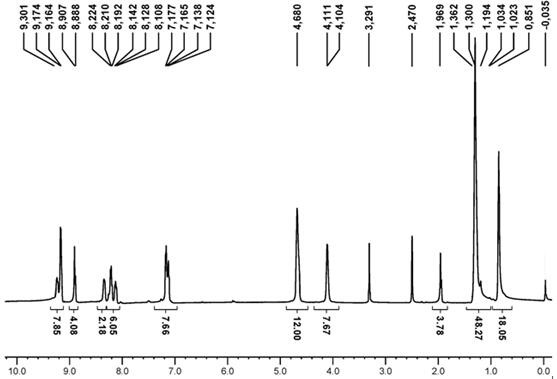

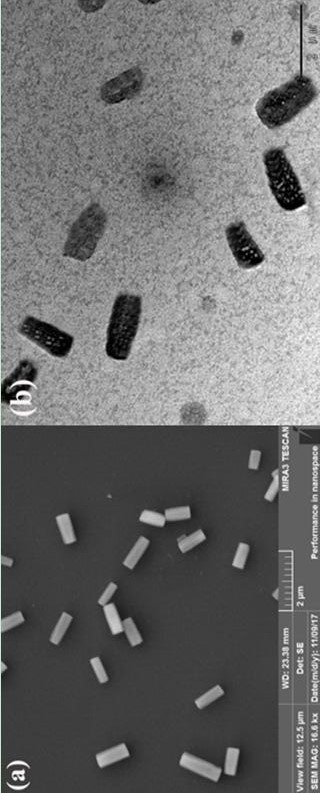

[0031] This example provides an organic ionic liquid metal corrosion inhibitor 4',4''''-(((((ethane-1,2-diylbis(oxygen))bis(ethane-2,1-di Base)) bis(oxygen)) bis(4,1-phenylene)) bis(1,1',1''-trihexyl-[4,2':6',4''-terpyridine]- 1,1',1''-three) preparation of bromide. Structural formula is as follows:

[0032] .

[0033] (1) Add 1mmol p-hydroxybenzaldehyde and 2mmol 4-acetylpyridine into a 50mL conical flask, add 10mL ethanol, stir well, add 0.36g potassium hydroxide to the solution, stir at 200 rpm for 1 minute, mix The solution turns brown, then add 3 mL of concentrated ammonia water with a mass fraction of 25%, seal it, stir at 300 rpm, react for 24 hours, add glacial acetic acid to adjust the pH to 7, a light yellow precipitate appears, suction filter, acetonitrile 75 °C Recrystallization gave a white solid, namely 4-([4,2':6',4''-terpyridine]-4'-yl)phenol.

[0034] (2) Add 30mL THF solution to the three-necked flask, take 1mmol of triethylene glycol and add it to the b...

Embodiment 2

[0041] This example provides an organic ionic liquid metal corrosion inhibitor 4',4''''-(((((ethane-1,2-diylbis(oxygen))bis(ethane-2,1-di Base)) bis(oxygen)) bis(4,1-phenylene)) bis(1,1',1''-trihexyl-[4,2':6',4''-terpyridine]- Preparation of 1,1',1''-tri)bromide. This example is consistent with Example 1 if there is no special description.

[0042] (1) Add 2mmol p-hydroxybenzaldehyde and 4mmol 4-acetylpyridine into a 50mL conical flask, add 10mL ethanol, stir well, add 0.75g potassium hydroxide to the solution, stir at 200 rpm for 1 minute, mix The solution turns brown, then add 3 mL of concentrated ammonia water with a mass fraction of 25%, seal it, stir at 500 rpm, and add glacial acetic acid to adjust the pH to 7 after reacting for 24 hours. A light yellow precipitate appears, suction filter, and 8 ml of acetonitrile 75 °C recrystallization to obtain a white solid, namely 4-([4,2':6',4''-terpyridine]-4'-yl)phenol.

[0043] (2) Add 61mL THF solution into the three-necked f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com