Biochar-manganese composite material coated with biochar as well as preparation method and application of biochar-manganese composite material

A technology of manganese composite material and biochar, which is applied to the application of the above composite material in the restoration of Tl-containing groundwater, biochar-manganese composite material, and the preparation field of the above composite material, which can solve the problems of multiple pore structures, large specific surface area, and low Oxidation properties and other problems, to achieve the effect of easy large-scale production, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

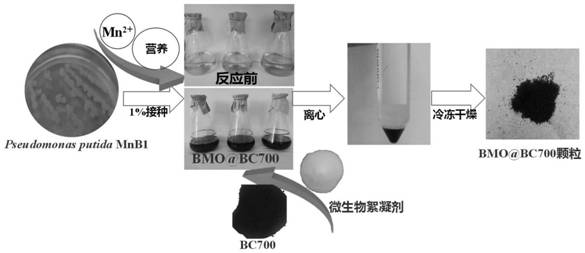

[0036] The whole process can be referred to figure 1 .

[0037] (1) Take a ring Pseudomonas PUTIDA MN B1 (ATCC 23483) (size of 1-10 μm) strain, after high temperature and high pressure sterilization Nb liquid medium (containing 10 g / L protein, 3g / L beef powder, 5g / L NaCl, pH = 7) amplified 24h;

[0038] (2) 1 ml of the above-mentioned cultured bacterial liquid in a certain volume of growth medium (containing 0.5 g / L yeast, 0.222 g / l) CaCL 2 , 0.8118g / L MGSO 4 · 7h 2 O, 0.001G / L FECL 3 · 6h 2 O, 2.38g / L HEPES (pH = 7) and 1ml / L trace elements (including 6.4mg / l Cuso 4 44mg / l znso 4 · 7h2 O, 20mg / L CoCl 2 · 6h 2 O, 13mg / L Na 2 MOO 4 · 2h 2 O), the adjustment of the initial bacterial concentration bacteria OD600≈0.8, provided the initial Mn (II) at a concentration of 30mg / L; reacted at 26 ℃, 150rpm dark reaction 3d, to form a black suspension.

[0039] (3) wheat straw was added at 700 ℃ biocoke 6h of sterile charcoal (through 400 mesh) was added to the bla...

Embodiment 2

[0043] (1) Pseudomonas putida Mn B1 to select NB solid medium after autoclaving (containing 10g / L peptone, 3g / L beef extract powder, 5g / L NaCl, 20g / L agar, pH = 7) were incubated after incubation 24h, Cultivation one loopful of strain in the well-NB liquid medium after autoclaving (containing 10g / L peptone, 3g / L beef extract powder, 5g / L NaCl, pH = 7) was amplified 24h; take 1mL bacteria (0.15g / L ferrous ammonium sulfate, 0.15g / L sodium citrate, 0.075g / L yeast extract, 0.05g / L sodium pyrophosphate) in the nutrient medium, adjustment of the initial bacterial concentration OD600 ≈0.8;

[0044] (2) deg.] C while adding 800 to the system sterile charcoal biochar walnut shell (200 mesh) and 15mg / L of Mn (II), and the reaction was placed 30 ℃, shaking at 200rpm 5d dark reaction conditions, the reduction processes Mn (II) to a concentration of 0.086mg / L;

[0045] (3) adding 2mg / L Bioflocculant 24h the reaction to the reaction system, the resulting precipitate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com