Supported noble metal compound as well as preparation and application thereof

A technology of noble metals and compounds, applied in electrolytic components, electrodes, electrolytic processes, etc., can solve the problems of complex preparation process of noble metal compound catalysts, high-temperature reactions, etc., and achieve the effects of improving selectivity and activity, mild reaction conditions, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The first step: uniformly disperse chloroplatinic acid and Vulcan carbon in water, stir for 30 minutes, and the loading of Pt is 10%;

[0030] The second step: the solution obtained in the first step is heated and stirred, and the solution is evaporated to dryness to obtain a solid powder precursor (Pt accounts for 10% of the mass fraction of the solid powder precursor), and the obtained solid powder precursor is mixed in argon / hydrogen atmosphere, heated at 150°C for 1h to obtain a carbon-supported platinum precursor, and the heating rate was 10°C / min;

[0031] Step 3: Put the carbon-supported platinum single substance precursor and sulfur powder obtained in the second step in two magnetic boats at a ratio of 1:10, and heat in argon / hydrogen mixed gas at 250°C for 1 hour, and the sulfur powder Sublimation and reaction with the carbon-supported platinum single substance precursor to obtain a carbon-supported platinum sulfide catalyst, wherein the heating rate is 10°C / mi...

Embodiment 2

[0033] The first step: uniformly disperse chloroplatinic acid and Vulcan carbon in water, stir for 30 minutes, and the loading of Pt is 5%;

[0034] The second step: the solution obtained in the first step is heated and stirred, and the solution is evaporated to dryness to obtain a solid powder precursor (Pt accounts for 5% of the mass fraction of the solid powder precursor), and the obtained solid powder precursor is mixed in argon / hydrogen atmosphere, heated at 150°C for 1h to obtain a carbon-supported platinum precursor, and the heating rate was 10°C / min;

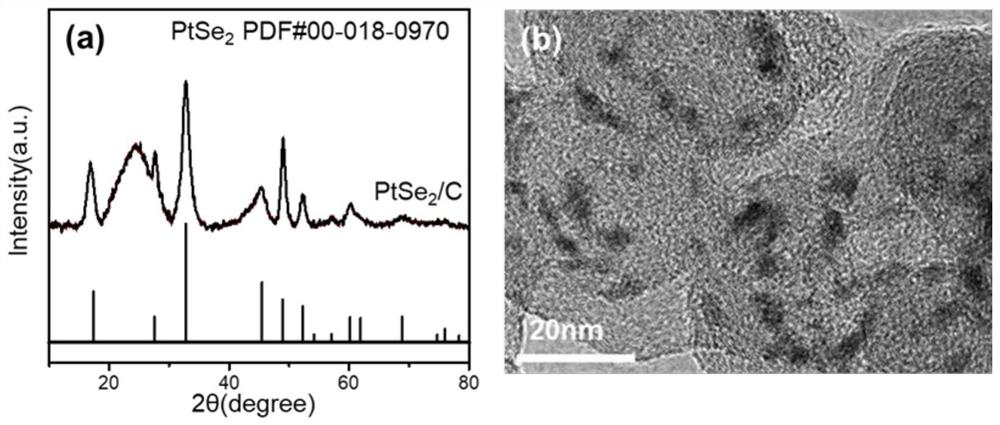

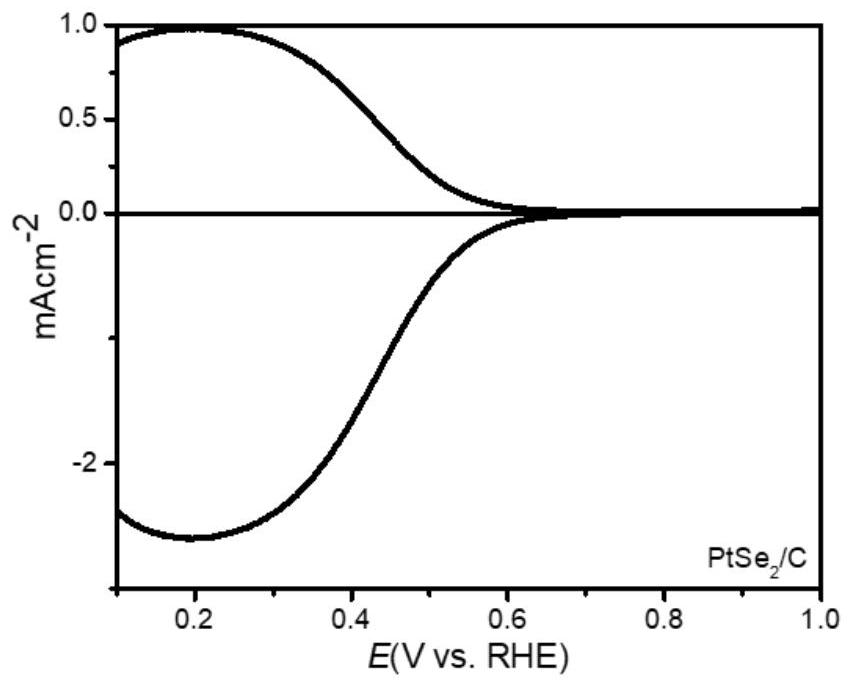

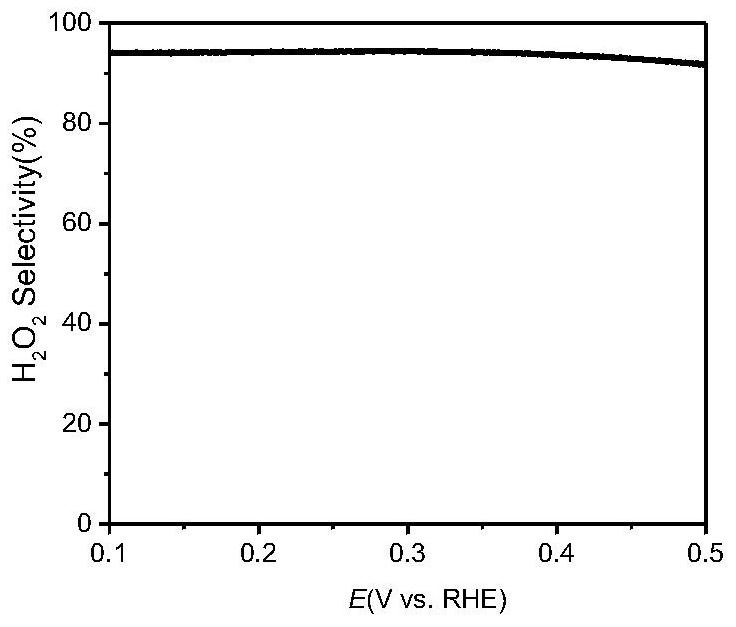

[0035] Step 3: Put the carbon-supported platinum simple substance precursor and selenium powder obtained in the second step in two magnetic boats at a ratio of 1:15, heat in argon at 350°C for 1 hour, and sublimate the selenium powder with The carbon-supported platinum simple substance precursor is reacted to obtain a carbon-supported platinum diselenide catalyst, wherein the heating rate is 10°C / min, and selenium powder...

Embodiment 3

[0037] The first step: uniformly disperse potassium chloroplatinate and carbon nanotubes in water, stir for 30 minutes, and the loading of Pt is 20%;

[0038] The second step: the solution obtained in the first step is heated and stirred, and the solution is evaporated to dryness to obtain a solid powder precursor (Pt accounts for 20% of the mass fraction of the solid powder precursor), and the obtained solid powder precursor is mixed in argon / hydrogen atmosphere, heated at 150°C for 1h to obtain a carbon-supported platinum precursor, and the heating rate was 10°C / min;

[0039] The third step: put the carbon-supported platinum simple substance precursor obtained in the second step and the tellurium powder in two magnetic boats at a ratio of 1:2, and heat at 450°C for 1 hour in argon gas, and the tellurium powder sublimates, and The carbon-supported platinum simple substance precursor is reacted to obtain a carbon-supported platinum ditelluride catalyst, wherein the heating rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com