Preparation method and application of solid electrolyte

A solid-state electrolyte and solid-state technology, applied in the direction of solid electrolyte, electrolyte, non-aqueous electrolyte, etc., can solve the problem of narrow electrochemical window, achieve the effect of wide electrochemical window, not easy to micro-short circuit, and reduce the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a method for preparing a solid electrolytic cell, comprising the following steps:

[0041] The sodium-containing salt, phosphorus-containing salt, zirconium oxide and silicon oxide are first mixed, and then calcined to obtain a sodium zirconium phosphate precursor;

[0042] After the sodium zirconium silicophosphate precursor, binder and sodium metasilicate are mixed for the second time, tablet pressing and liquid phase sintering are performed sequentially to obtain the solid electrolyte.

[0043] In the present invention, unless otherwise specified, all preparation materials are commercially available products well known to those skilled in the art.

[0044] In the present invention, sodium-containing salt, phosphorus-containing salt, zirconium oxide and silicon oxide are first mixed, and then calcined to obtain a sodium zirconium phosphate precursor.

[0045] In the present invention, the sodium-containing salt is preferably sodium carbonate. ...

Embodiment 1

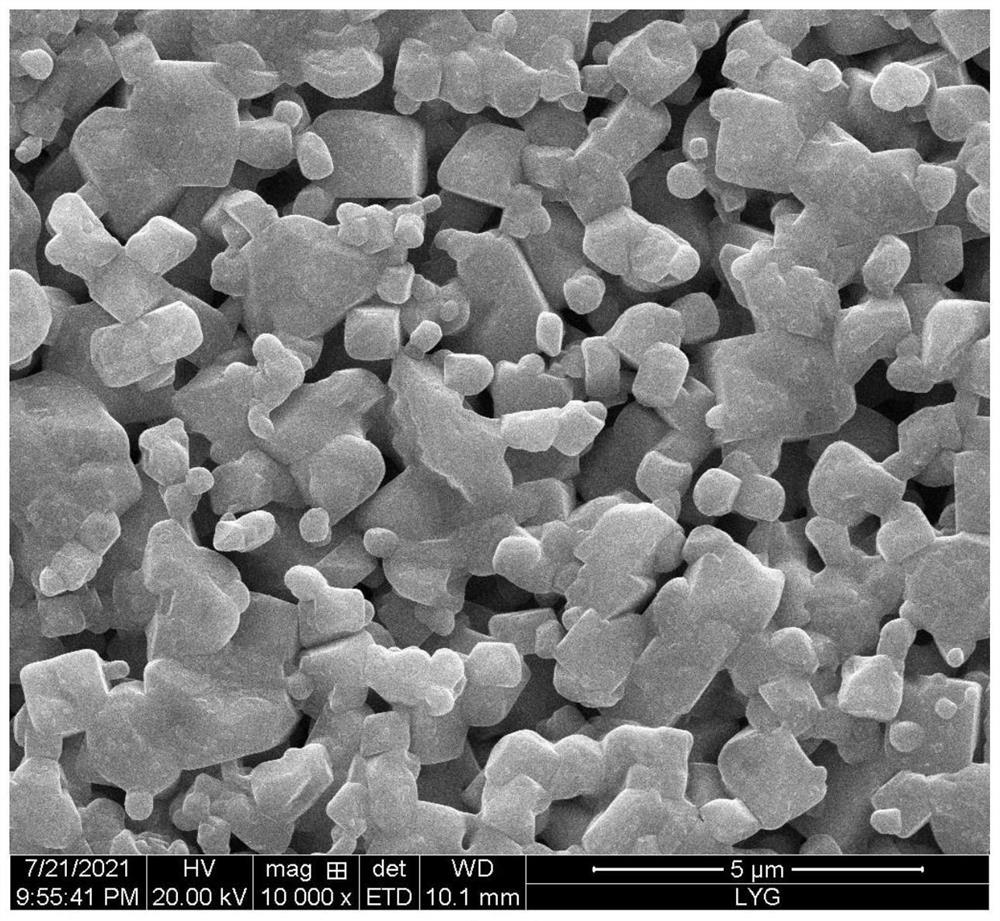

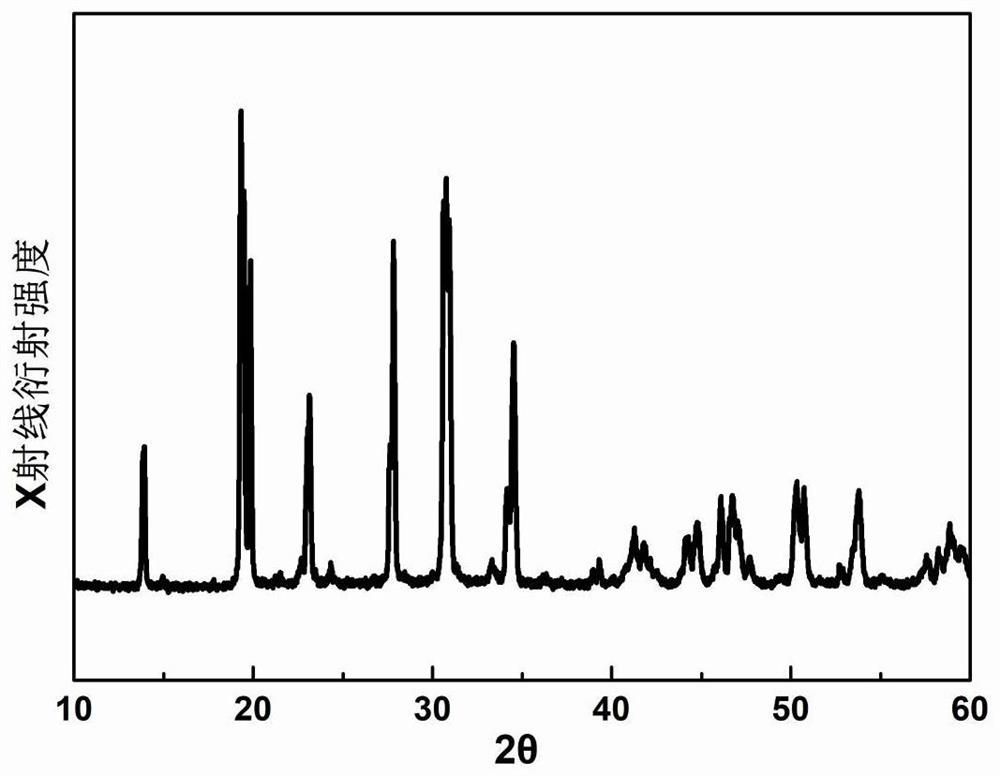

[0072] 0.9937g of sodium carbonate, 1.5403g of zirconia, 0.7511g of silicon dioxide and 0.7548g of ammonium dihydrogen phosphate are placed in a planetary ball mill, 24g of zirconia balls and 4mL of ethanol are added for mixed ball milling. at 400 rpm for 12 hours; after vacuum drying at 80°C for 12 hours, calcining at 1000°C in an air atmosphere for 12 hours, cooling to room temperature, and grinding for 15 minutes to obtain a sodium zirconium phosphate precursor;

[0073] Mix 1.025g of polyvinyl alcohol and 23.75g of deionized water, and put it in an oil bath at 80°C for 1 hour under stirring until the polyvinyl alcohol is completely dissolved to obtain an aqueous solution of polyvinyl alcohol;

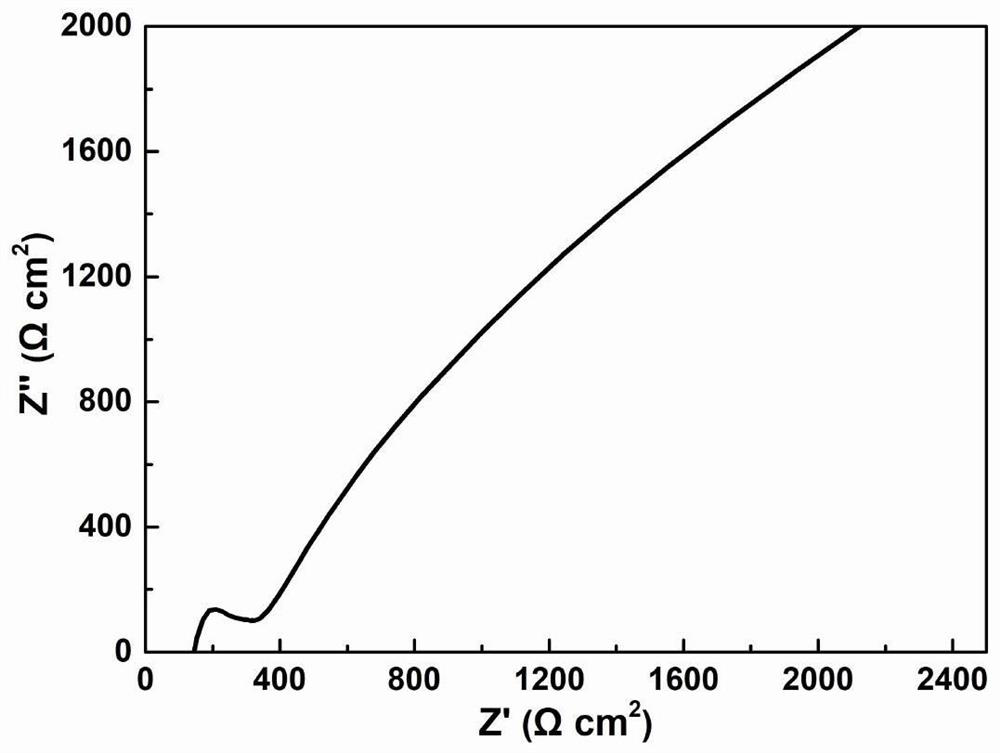

[0074] 3.2g of the sodium zirconium phosphate precursor and 0.16g sodium metasilicate (5% of the zirconium phosphate precursor) were placed in a planetary ball mill, and 24g of zirconia and 4mL of ethanol were added for ball milling. The rotation speed of the ball mill is 400rpm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com