Natural zeolite adsorption microspheres as well as preparation method and application thereof

A technology of natural zeolite and adsorption microspheres, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problem of environmental protection and sustainable development strategy, reduce zeolite ammonia nitrogen removal rate, increase energy consumption, etc. problems, to achieve good ammonia nitrogen adsorption performance, good water environment stability, and easy control of the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this example, natural zeolite adsorption microspheres were prepared with different binder dosages.

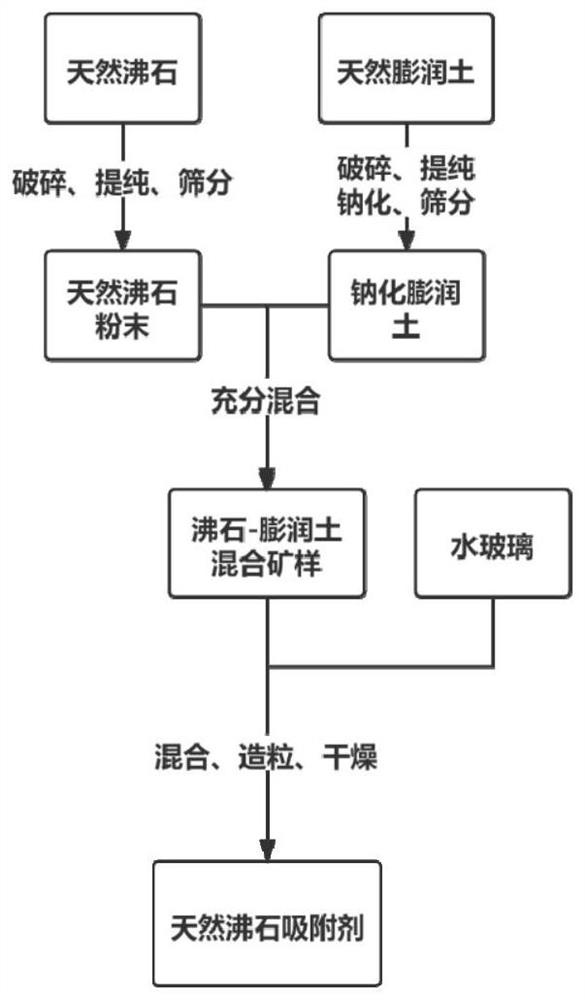

[0029] like figure 1 As shown, the natural zeolite is pulverized with a high-speed pulverizer and then sieved with a 200-mesh sieve for subsequent use. After pulverizing the natural bentonite with a high-speed pulverizer, add deionized water with a solid-to-liquid ratio of 1:10, and add sodium hexametaphosphate with a mass fraction of 0.3% and sodium carbonate with a mass fraction of 4%, mix and stir for 2 hours and let stand 1h, take the supernatant after standing still and centrifuge at 8000rpm for 3min, wash twice and then dry, crush the dried ore sample with a high-speed pulverizer and pass through a 200-mesh sieve to obtain sodium bentonite for later use. After fully mixing natural zeolite and sodium bentonite in a ratio of 7:3, add water glass solution with a mass fraction of 40% and an appropriate amount of water, mixed thoroughly and then granulated, dried t...

Embodiment 2

[0031] In this example, natural zeolite adsorption microspheres were prepared with different ratios of natural zeolite and sodium bentonite.

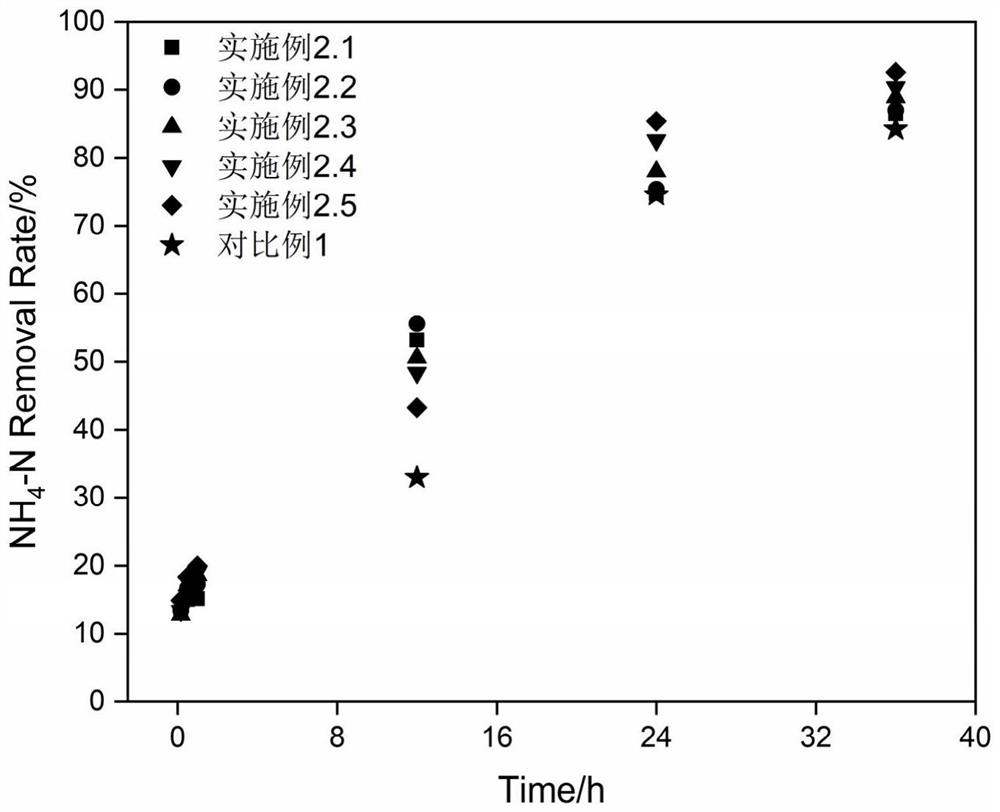

[0032]The natural zeolite is pulverized with a high-speed pulverizer and then sieved with a 200-mesh sieve for subsequent use. After pulverizing the natural bentonite with a high-speed pulverizer, add deionized water with a solid-to-liquid ratio of 1:10, and add sodium hexametaphosphate with a mass fraction of 0.3% and sodium carbonate with a mass fraction of 4%, mix and stir for 2 hours and let stand 1h, take the supernatant after standing still and centrifuge at 8000rpm for 3min, wash twice and then dry, crush the dried ore sample with a high-speed pulverizer and pass through a 200-mesh sieve to obtain sodium bentonite for later use. Fully mix natural zeolite and sodium bentonite in the ratio of 5:5, 6:4, 7:3, 8:2, 9:1 (Example 2.1, 2.2, 2.3, 2.4, 2.5) and mix at 40mL / 100g The dosage of the ore sample is to add water glass solution w...

Embodiment 3

[0034] In this example, natural zeolite adsorption microspheres were prepared by impregnating different concentrations of PVA.

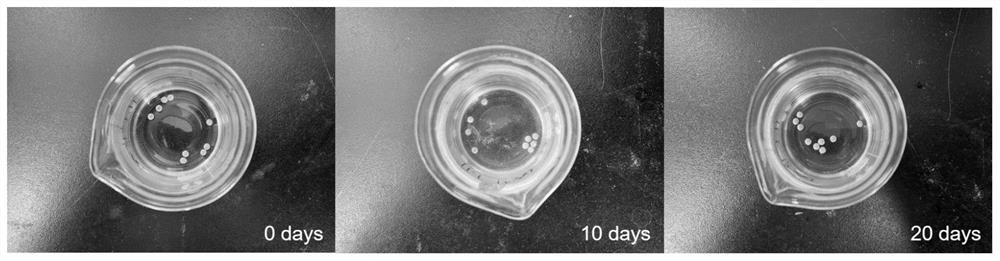

[0035] The natural zeolite is pulverized with a high-speed pulverizer and then sieved with a 200-mesh sieve for subsequent use. After pulverizing the natural bentonite with a high-speed pulverizer, add deionized water with a solid-to-liquid ratio of 1:10, and add sodium hexametaphosphate with a mass fraction of 0.3% and sodium carbonate with a mass fraction of 4%, mix and stir for 2 hours and let stand 1h, take the supernatant after standing still and centrifuge at 8000rpm for 3min, wash twice and then dry, crush the dried ore sample with a high-speed pulverizer and pass through a 200-mesh sieve to obtain sodium bentonite for later use. Fully mix natural zeolite and sodium bentonite at a ratio of 7:3, then add water glass solution with a mass fraction of 40% and an appropriate amount of water according to the amount of 40mL / 100g mixed ore sample, mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com