Lithium-supplementing modified silicon material as well as preparation method and application thereof

A technology for modifying silicon and silicon materials, applied in the preparation/purification of carbon, silicon, silicate, etc., can solve the problems of dangerous operation, difficulty in uniformly dispersing lithium, unsafe, etc., to solve uneven mixing, process steps Less and more efficient lithium doping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

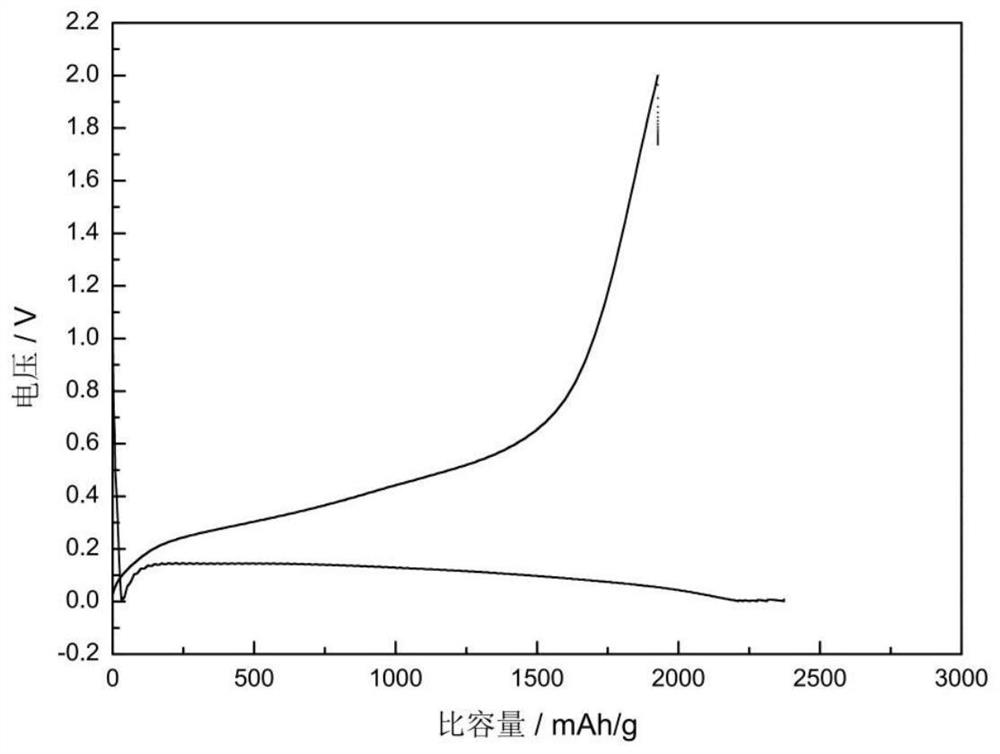

Embodiment 1

[0045] Step 1) Preparation of organolithium solution: in an environment of 5°C and argon atmosphere, weigh 95g of methyl bromide and 8g of metal lithium and stir them with a magnetic stirrer to completely dissolve them in 200mL of ether (analytical pure AR), stirring time At 2h, a suspension A was obtained; the suspension A was filtered to obtain a pure organolithium solvent B;

[0046] In a normal environment, weigh 300g of silicon oxide and completely disperse it in 1000mL of deionized water to obtain silica slurry C;

[0047] Step 2) Mixing: Mechanically mix the organic lithium solvent B with the silicon-oxygen slurry C, and the mechanical mixing time is 5 hours to obtain the lithium-supplementing modified silicon-oxygen slurry D; place the lithium-supplementing modified silicon-oxygen slurry D on Carry out suction filtration and water washing in the suction filtration bottle, the number of times of water washing is 3 times, place the lithium-supplementing modified silicon-...

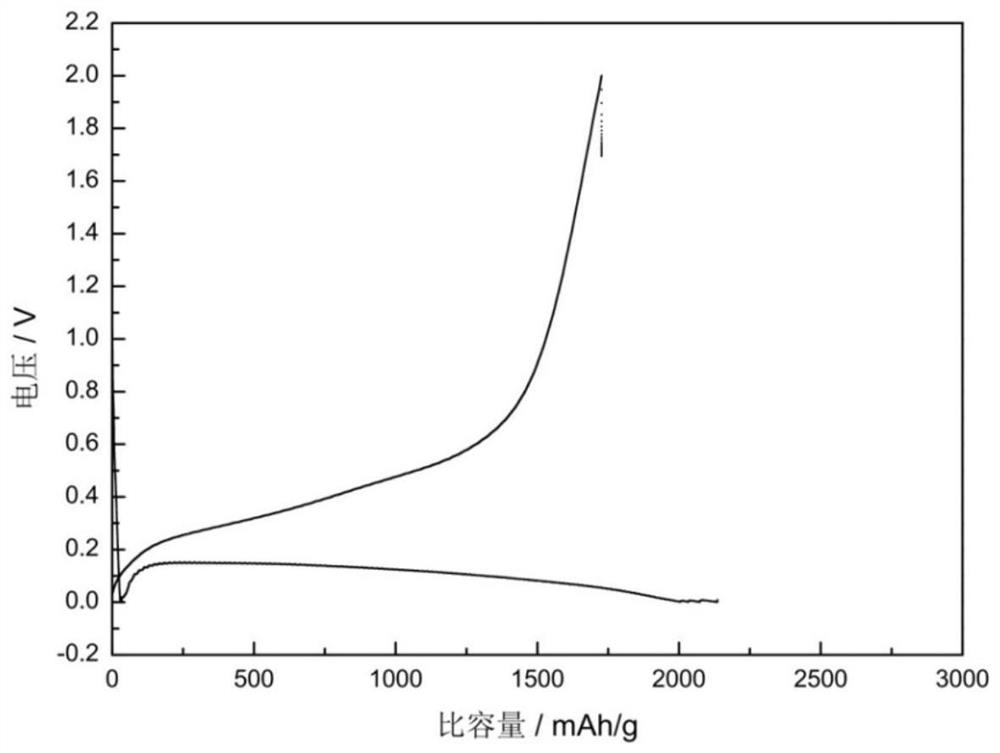

Embodiment 2

[0051] Step 1) Preparation of organolithium solution: in an environment of 5°C and argon atmosphere, weigh 95g of methyl bromide and 8g of metal lithium and stir them with a magnetic stirrer to completely dissolve them in 200mL of ether (analytical pure AR), stirring time At 2h, a suspension A was obtained; the suspension A was filtered to obtain a pure organolithium solvent B;

[0052] In a normal environment, weigh 300g of silicon oxide and completely disperse it in 1000mL of deionized water to obtain silica slurry C;

[0053] Step 2) Mixing: Mechanically mix the organic lithium solvent B with the silicon-oxygen slurry C, and the mechanical mixing time is 5 hours to obtain the lithium-supplementing modified silicon-oxygen slurry D; place the lithium-supplementing modified silicon-oxygen slurry D on Carry out suction filtration and water washing in the suction filtration bottle, the number of times of water washing is 3 times, place the lithium-supplementing modified silicon-...

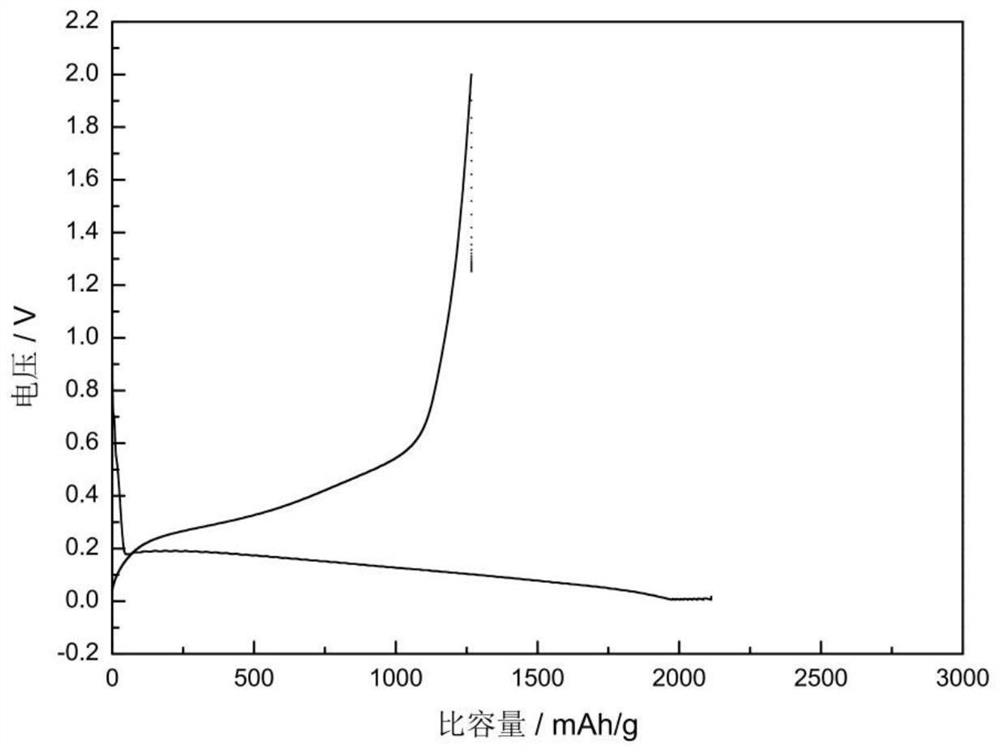

Embodiment 3

[0057] Step 1) Preparation of organolithium solution: in an environment of 5°C and argon atmosphere, weigh 95g of methyl bromide and 10g of metal lithium and stir them with a magnetic stirrer to completely dissolve them in 200mL of ether (analytical pure AR), stirring time At 3h, a suspension A was obtained; the suspension A was filtered to obtain a pure organolithium solvent B;

[0058] In a normal environment, weigh 300g of silicon oxide and completely disperse it in 1000mL of deionized water to obtain silica slurry C;

[0059] Step 2) Mixing: Mechanically mix the organic lithium solvent B with the silicon-oxygen slurry C, and the mechanical mixing time is 5 hours to obtain the lithium-supplementing modified silicon-oxygen slurry D; place the lithium-supplementing modified silicon-oxygen slurry D on Carry out suction filtration and water washing in the suction filtration bottle, the number of times of water washing is 4 times, place the lithium-supplementing modified silicon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com