High-performance hydrogel-nanofiber-based wearable friction generator and preparation method thereof

A triboelectric generator and nanofiber technology, applied in the field of materials, can solve the problems of reduced accuracy and stability of biomechanical signals, limited power output performance of stretchable equipment, poor biocompatibility, etc., and achieves a simple and high-quality preparation method. Good stretchability and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

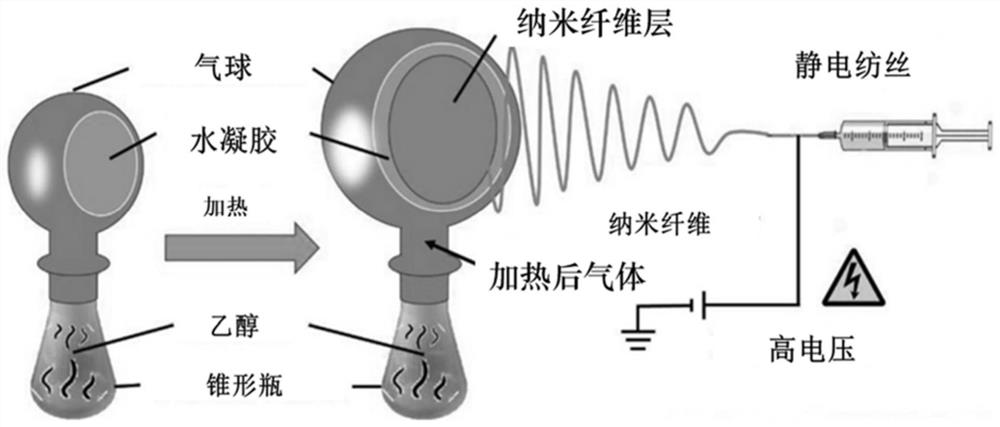

[0059] The preparation method of the high-performance hydrogel-nanofiber-based wearable triboelectric generator of the present invention comprises the following steps: preparing 5 mL of LiCl aqueous solution with a concentration of 8 mol / L, adding acrylamide powder so that the mass concentration of acrylamide is 14wt% ; Then add N, N'-methylenebisacrylamide, N, N, N', N'-tetramethylethylenediamine and potassium persulfate each 0.001g to obtain a mixed solution; the prepared mixed solution is transferred to 3D Print the mold and place it at room temperature for 24 hours to form a conductive hydrogel; refer to figure 1 , put ethanol in the Erlenmeyer flask, put the mouth of the balloon on the mouth of the Erlenmeyer bottle, adhere the conductive hydrogel to the surface of the balloon on the mouth of the Erlenmeyer bottle, heat the Erlenmeyer flask to volatilize the ethanol, and use the volatilized ethanol The expansion of the balloon drives the stretching of the conductive hydro...

Embodiment 2

[0063] The preparation method of the high-performance hydrogel-nanofiber-based wearable triboelectric generator of the present invention comprises the following steps: preparing 5 mL of KCl aqueous solution with a concentration of 8 mol / L, adding acrylamide powder so that the mass fraction of acrylamide is 14wt% ; Then add N, N'-methylenebisacrylamide, N, N, N', N'-tetramethylethylenediamine and potassium persulfate each 0.001g to obtain a mixed solution; the prepared mixed solution is transferred to 3D Print the mold and place it at room temperature for 24 hours to form a conductive hydrogel; refer to figure 1 , put ethanol in the Erlenmeyer flask, put the mouth of the balloon on the mouth of the Erlenmeyer bottle, adhere the conductive hydrogel to the surface of the balloon on the mouth of the Erlenmeyer bottle, heat the Erlenmeyer flask to volatilize the ethanol, and use the volatilized ethanol The expansion of the balloon drives the stretching of the conductive hydrogel; t...

Embodiment 3

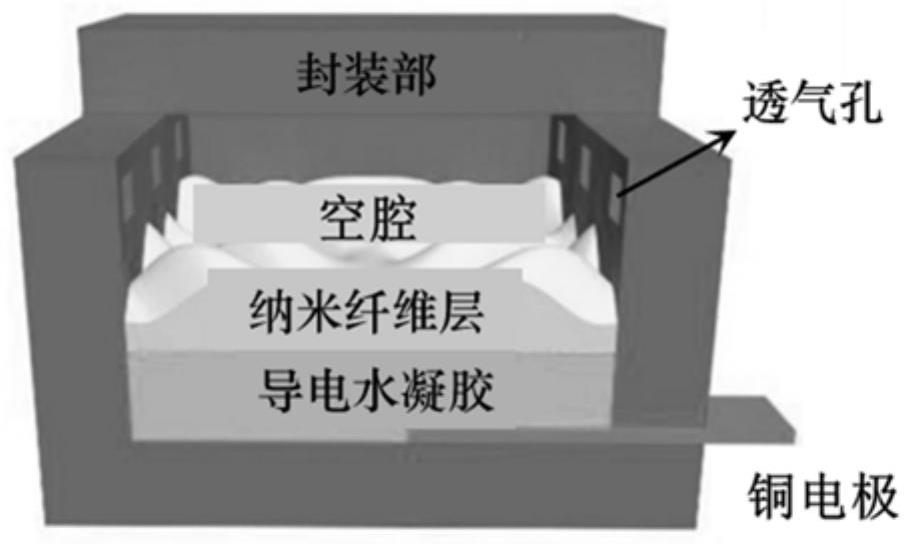

[0065] A high-performance hydrogel-nanofiber-based wearable triboelectric generator proposed by the present invention includes a hydrogel-nanofiber composite film layer, an encapsulation unit and a copper electrode;

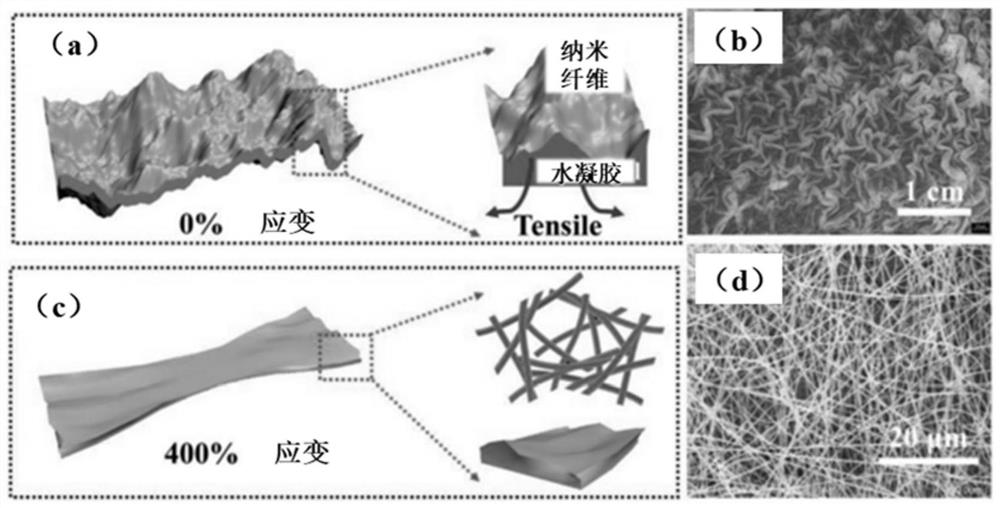

[0066] The hydrogel-nanofiber composite film layer is composed of a conductive hydrogel layer and a nanofiber layer formed on the conductive hydrogel layer; the conductive hydrogel layer is composed of an acrylamide ion-conductive hydrogel The conductive ionic salt is sodium chloride; the nanofiber layer is prepared from polylactic acid through electrospinning technology, and is wrinkled in a natural state;

[0067] refer to figure 2 , the encapsulation part comprises the top surface of the encapsulation part, the bottom surface of the encapsulation part and the side face of the encapsulation part, the top surface of the encapsulation part, the bottom surface of the encapsulation part and the side face of the encapsulation part form a cavity, and the hydrogel-na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com