Bacteriostatic laundry gel bead and preparation method thereof

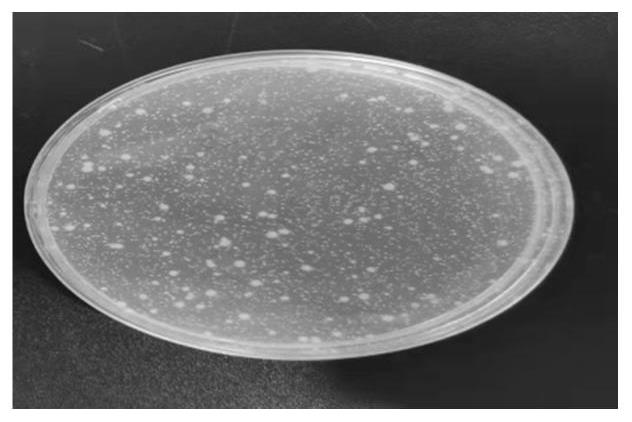

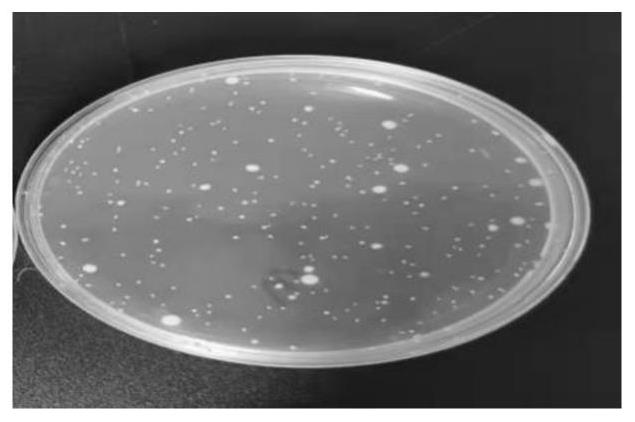

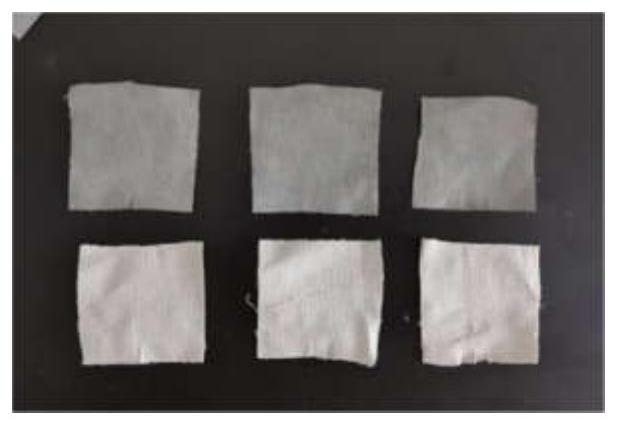

A technology of laundry beads and mass percentage, which is applied in the field of daily chemicals, can solve the problems of increased toxicity, easy oxidative denaturation, long contact time, etc., and achieve the effect of increasing the dosage and inhibiting Staphylococcus aureus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In the present embodiment, the ingredients contained in the antibacterial laundry pod beads and the mass percentage of each ingredient are: fatty alcohol polyoxyethylene ether sodium sulfate 30%; dodecylbenzenesulfonic acid 16%; fatty acid methyl ester ethoxylate 10% %; Monoglyceryl Laurate 5%; Cocamidopropyl Betaine 5%; Triethanolamine 1%; Glycerin 3%; Deionized Water 30%.

[0041] In the present embodiment, the carbon chain of the fatty alcohol in the fatty alcohol polyoxyethylene ether sodium sulfate is C12, and the mass percentage of the fatty alcohol with the carbon chain being C12 in the fatty alcohol polyoxyethylene ether sodium sulfate is 70%, and the average EO The addition number is 1.5; the mass percentage of methyl laurate ethoxylate in the fatty acid methyl ester ethoxylate is 95%, and the average EO addition number is 12.

Embodiment 2

[0043] In the present embodiment, the ingredients contained in the antibacterial laundry pod beads and the mass percentage of each ingredient are: fatty alcohol polyoxyethylene ether sodium sulfate 48%; dodecylbenzenesulfonic acid 16%; fatty acid methyl ester ethoxylate 16% %; Monoglyceryl Laurate 8%; Cocamidopropyl Betaine 5%; Triethanolamine 1%; Glycerin 3%; Deionized Water 3%.

[0044] In the present embodiment, the carbon chain of the fatty alcohol in the fatty alcohol polyoxyethylene ether sodium sulfate is C12, and the mass percentage of the fatty alcohol with the carbon chain being C12 in the fatty alcohol polyoxyethylene ether sodium sulfate is 70%, and the average EO The addition number is 1.5; the mass percentage of methyl laurate ethoxylate in the fatty acid methyl ester ethoxylate is 95%, and the average EO addition number is 12.

Embodiment 3

[0046] In the present embodiment, the ingredients contained in the antibacterial laundry beads and the mass percentage of each ingredient are: fatty alcohol polyoxyethylene ether sodium sulfate 39%; dodecylbenzenesulfonic acid 16%; fatty acid methyl ester ethoxylate 13% %; Monoglyceryl Laurate 6.5%; Cocamidopropyl Betaine 5%; Triethanolamine 1%; Glycerin 3%; Deionized Water 16.5%.

[0047] In the present embodiment, the carbon chain of the fatty alcohol in the fatty alcohol polyoxyethylene ether sodium sulfate is C12, and the mass percentage of the fatty alcohol with the carbon chain being C12 in the fatty alcohol polyoxyethylene ether sodium sulfate is 70%, and the average EO The addition number is 1.5; the mass percentage of methyl laurate ethoxylate in the fatty acid methyl ester ethoxylate is 95%, and the average EO addition number is 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com