N polar surface AlGaN-based ultraviolet photoelectric detector epitaxial structure and preparation method thereof

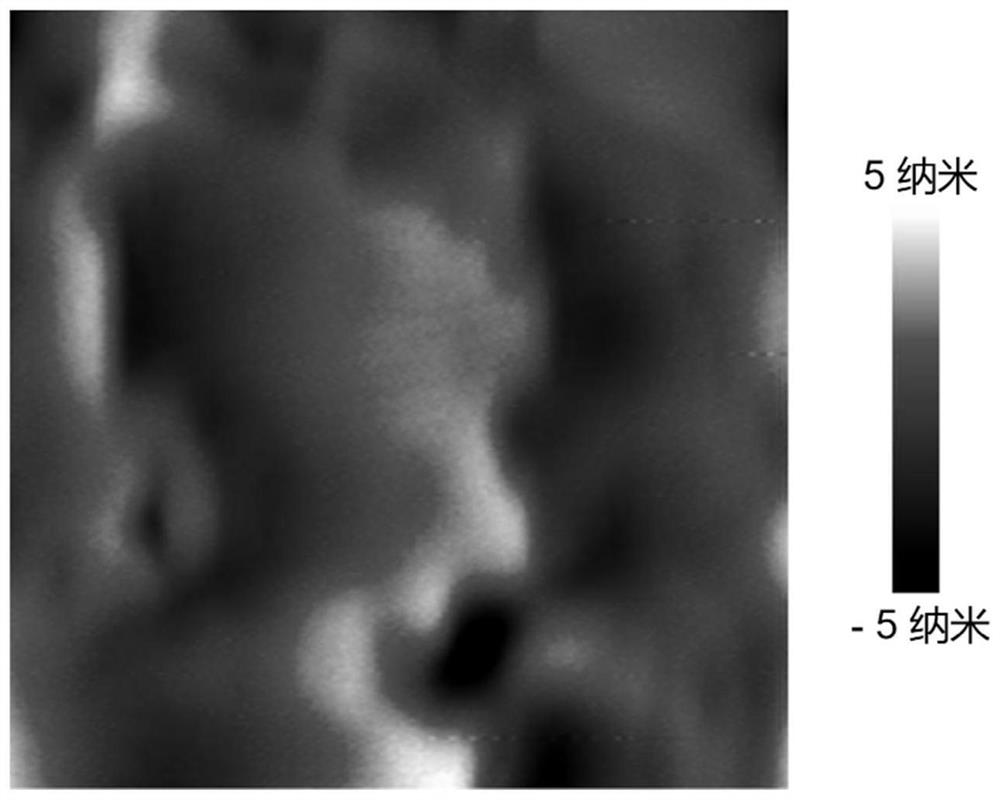

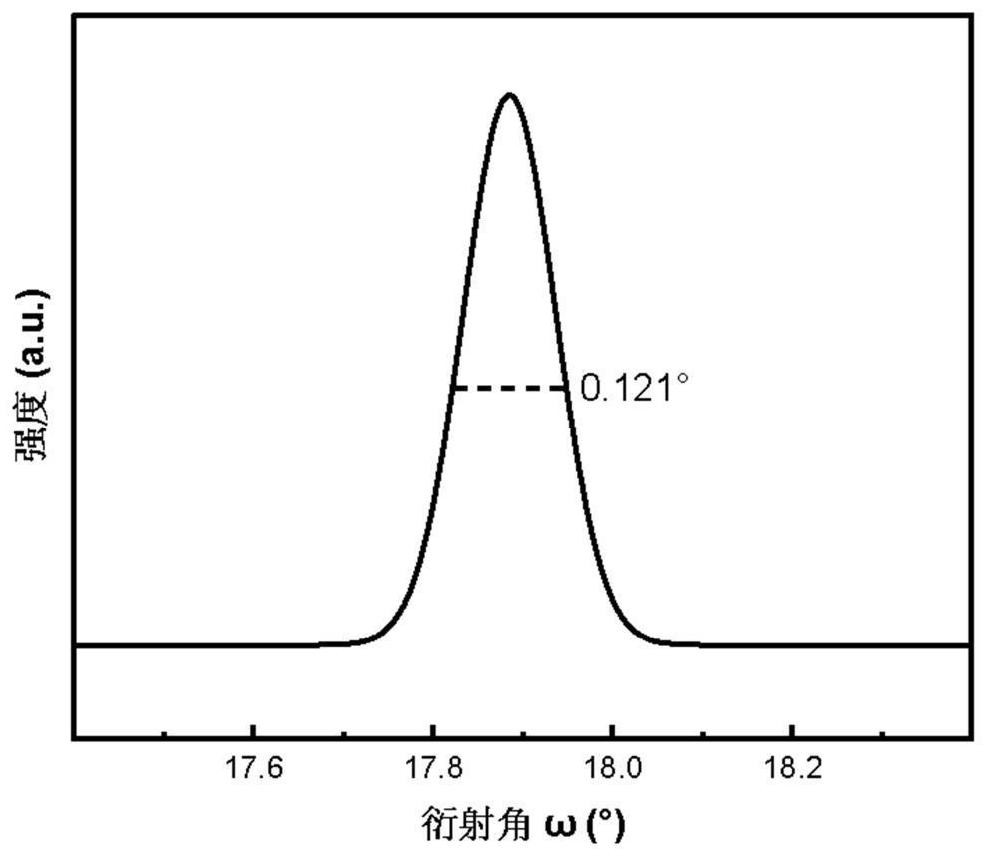

A technology of electrical detectors and epitaxial structures, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of weak high-temperature thermal stability and inability to effectively improve surface quality, so as to improve high-temperature stability and suppress back-to-furnace etching reactions , the effect of reducing dislocation density and surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

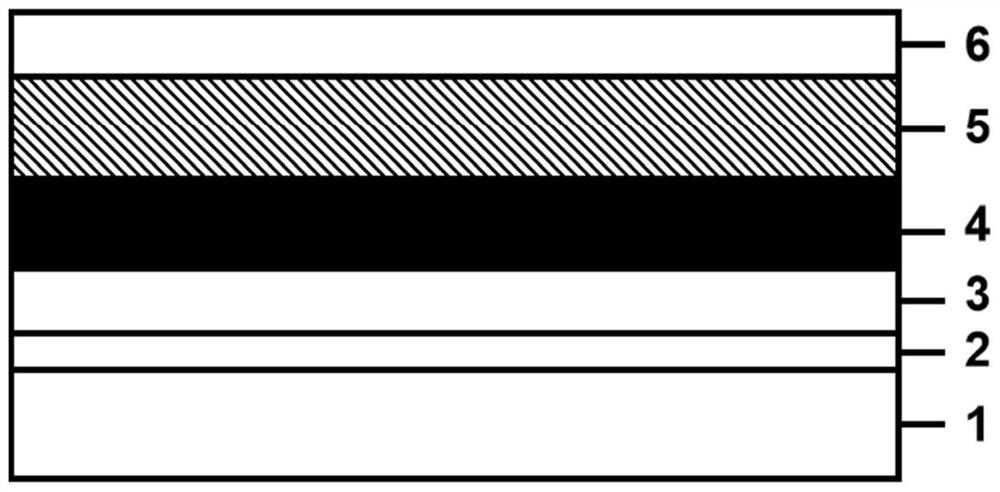

[0037] This embodiment provides a method for preparing an epitaxial structure of an AlGaN ultraviolet photodetector with an N-polar surface, the method comprising:

[0038] The silicon substrate is a single crystal silicon substrate, the Si(111) close-packed surface is used as the epitaxial surface, and the AlN [0001] direction is used as the epitaxial growth direction of the material;

[0039] Put the silicon substrate into the three mediums of acetone, absolute ethanol, and deionized water in sequence, ultrasonically clean it in turn, rinse it with deionized water after taking it out, and dry it with hot high-purity nitrogen;

[0040] Using a pulsed laser deposition process, put the silicon substrate into a vacuum chamber, raise the temperature to 420-500°C, and pump the vacuum to 2.0×10 -4 ~4.0×10 -4 torr, laser energy 250-320mJ, laser frequency 15-30Hz, nitrogen flow rate 2-10sccm, grow N-polar AlN film under N-rich conditions, Al source is AlN high-purity ceramic target;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com