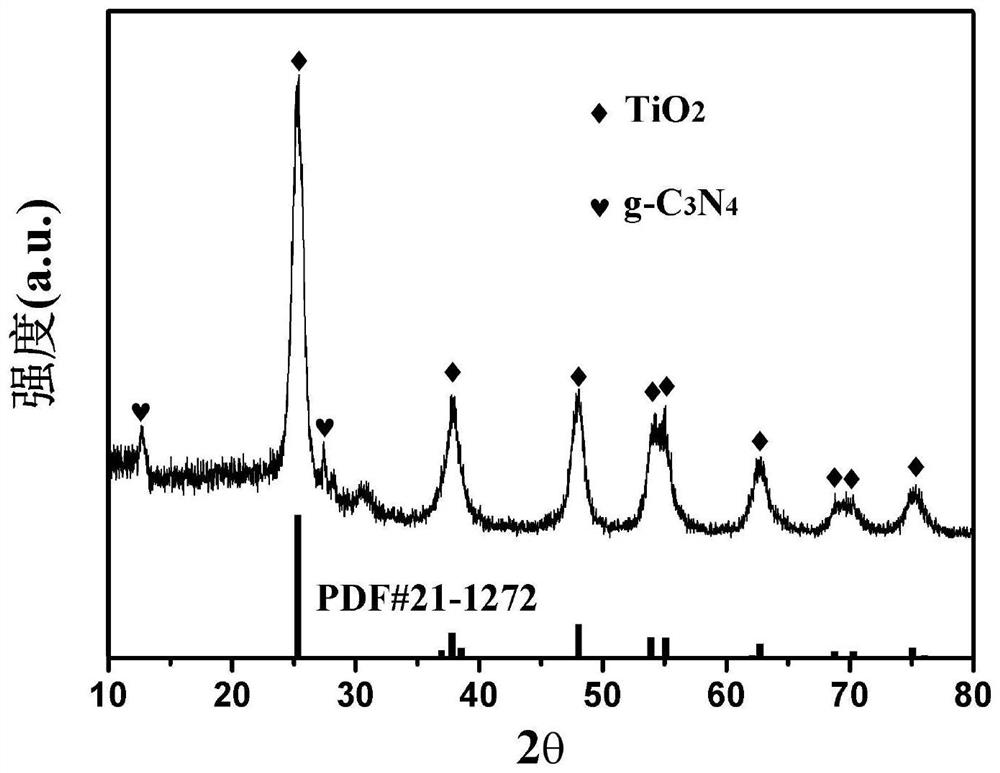

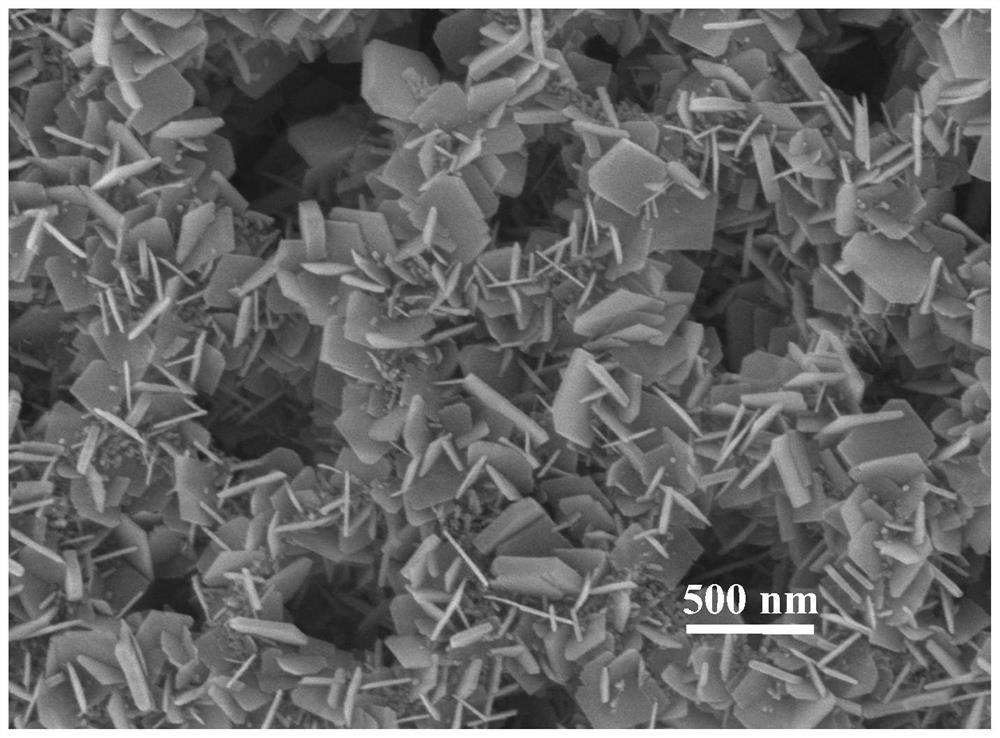

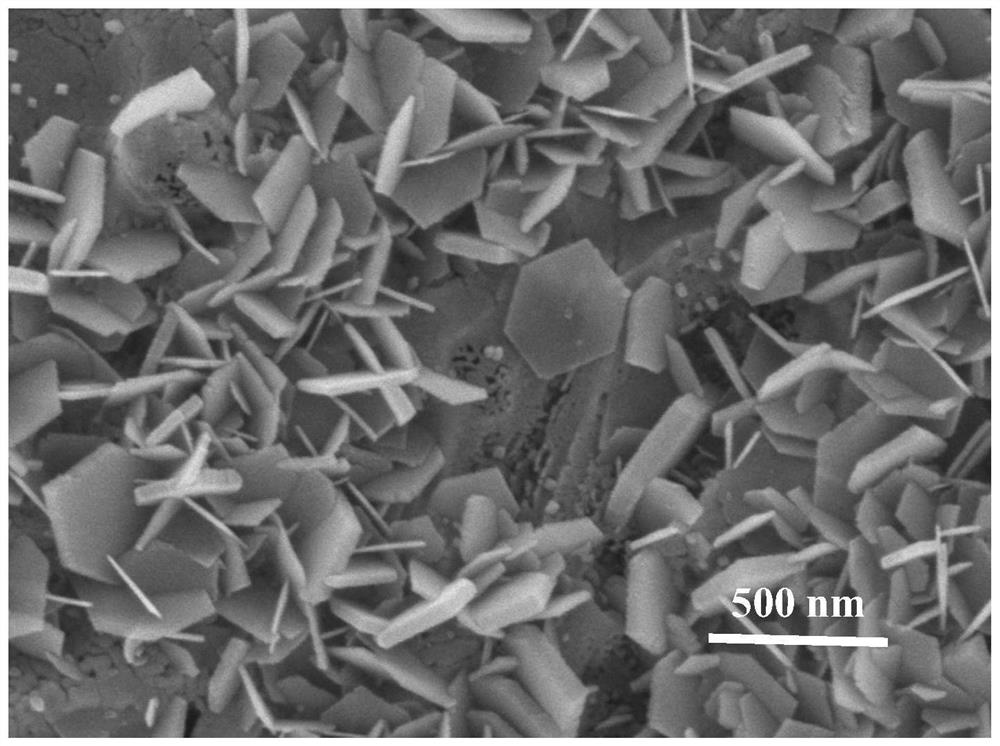

Hexagonal nanosheet composite film layer containing array macropores and preparation method of hexagonal nanosheet composite film layer

A composite film layer and hexagonal technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of photocatalyst secondary pollution degradation, low efficiency, etc., and achieve easy recycling and regeneration Recycling, solving secondary pollution, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for preparing a hexagonal nanosheet composite membrane layer containing array macropores:

[0048] Step 1: Measure tetrabutyl titanate, diethanolamine and absolute ethanol at a molar ratio of 1:1:24, respectively, 17ml of tetrabutyl titanate, 4.8ml of diethanolamine and 70ml of absolute ethanol, and pour them into a mixing container Stir in medium, the stirring speed is 400rad / min, and the stirring time is 10min, and the mixed solution A is obtained by stirring evenly;

[0049] Step 2, continuously drop 2ml of water into the mixed solution A, the molar ratio of water to tetrabutyl titanate used in step 1 is 2.2:1, the speed of water dripping into the mixed solution A is 15s / drop, and the water is Deionized water;

[0050] Step 3: Add 1.2g of polyethylene glycol 400 after the addition of water dropwise, the molar ratio of polyethylene glycol 400 to tetrabutyl titanate is 0.06:1; stir for 0.5h until uniform and stand for 1h to obtain a sol;

[0051] Step 4: Coa...

Embodiment 2

[0057] A method for preparing a hexagonal nanosheet composite membrane layer containing array macropores:

[0058] Step 1: Measure tetrabutyl titanate, diethanolamine and absolute ethanol at a molar ratio of 1:1:30, respectively, 17ml of tetrabutyl titanate, 4.8ml of diethanolamine and 88ml of absolute ethanol, and pour them into a mixing container Stir in medium, the stirring speed is 400rad / min, and the stirring time is 10min, and the mixed solution A is obtained by stirring evenly;

[0059] Step 2, continuously drop 2ml of water into the mixed solution A, the molar ratio of water to tetrabutyl titanate used in step 1 is 2.2:1, the speed of water dripping into the mixed solution A is 20s / drop, and the water is Deionized water;

[0060] Step 3: Add 1.4g of polyethylene glycol 400 after the addition of water dropwise, the molar ratio of polyethylene glycol 400 to tetrabutyl titanate is 0.07:1; stir for 0.6h until uniform and stand for 0.9h to obtain a sol;

[0061] Step 4: C...

Embodiment 3

[0066] A method for preparing a hexagonal nanosheet composite membrane layer containing array macropores:

[0067] Step 1: Measure tetrabutyl titanate, diethanolamine and absolute ethanol at a molar ratio of 1:1:32, respectively, and pour 17ml of tetrabutyl titanate, 4.8ml of diethanolamine and 93ml of absolute ethanol into a mixing container Stir, the stirring speed is 400rad / min, the stirring time is 10min, and the mixed solution A is obtained by stirring evenly;

[0068] Step 2, continuously drop 2ml of water into the mixed solution A, the molar ratio of water to tetrabutyl titanate used in step 1 is 2.2:1, the speed of water dropping into the mixed solution A is 16s / drop, and the water is Deionized water;

[0069] Step 3: Add 1.6g of polyethylene glycol 400 after the addition of water dropwise, the molar ratio of polyethylene glycol 400 to tetrabutyl titanate is 0.08:1; stir for 0.7h until uniform and stand for 0.8h to obtain a sol;

[0070] Step 4: Coat the obtained sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com