Preparation method of field emission micro-nano tungsten emitter

An emitter and field emission technology, applied in the field of powder metallurgy, can solve the problems of large particle size of powder raw materials, unsuitable emitters, large product pores, etc., to eliminate internal stress, achieve precise control, and improve the effect of opening porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

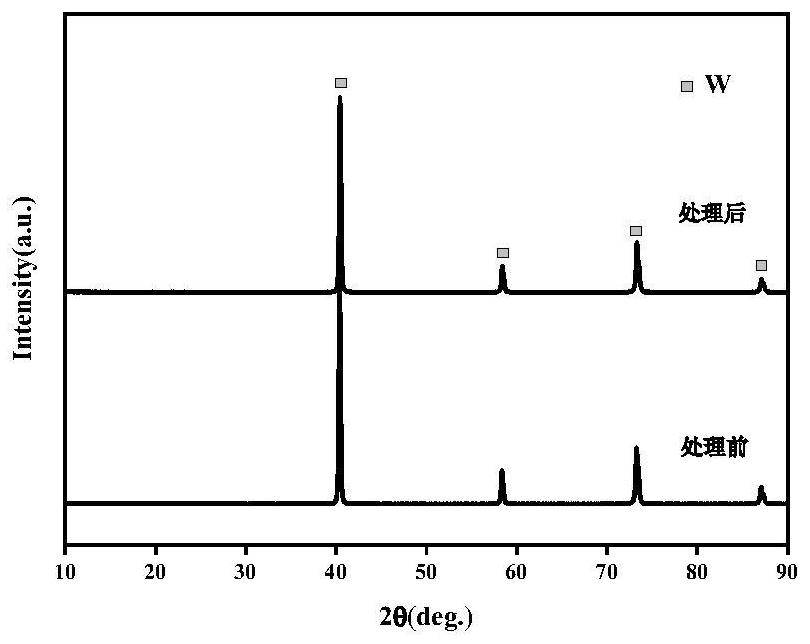

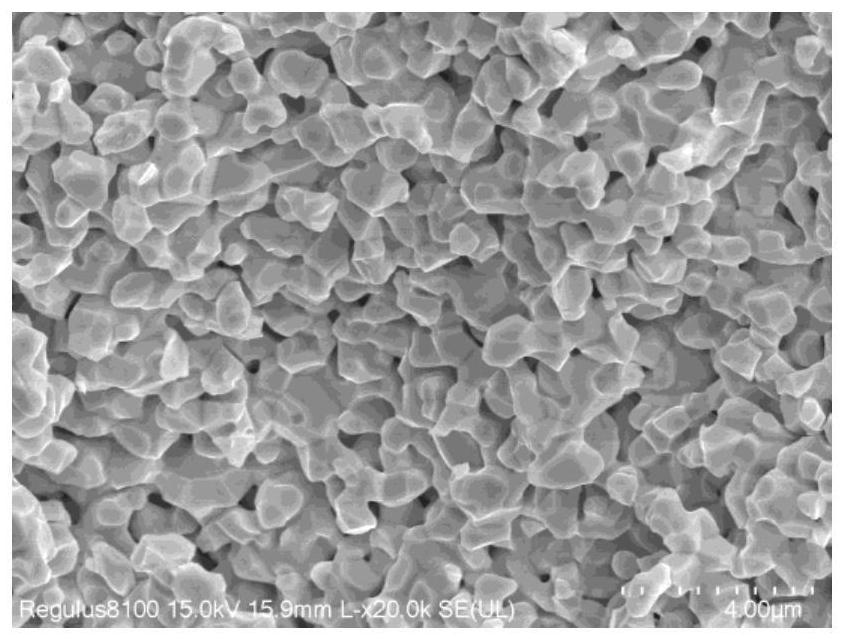

[0023] 1) The raw material powder is tungsten powder with a Fischer particle size of 0.3 μm and a purity greater than 99.9%;

[0024] 2) First clean the jet mill equipment, turn on the main control to preheat for 10-30 minutes, fill in high-purity nitrogen with a purity greater than 99.9%, start the grinding valve, adjust the grinding pressure to 0.5Mpa, add raw tungsten powder into the grinding chamber to deagglomerate, and Adjust the frequency of the sorting wheel to 40Hz. After collecting all the powder, repeat the above operation to obtain the jet milled powder twice;

[0025] 3) The jet-milled powder is heated up to 300°C at 5°C / min in an atmosphere of high-purity hydrogen with a purity greater than 99.9%, kept for 180min, and then calcined once to eliminate the internal stress generated during the jet-milling process;

[0026] 4) The calcined powder is mixed with an organic binder (microcrystalline wax is 55%, polyethylene wax is 3%, linear low density polyethylene is 10...

Embodiment 2

[0030] 1) The raw material powder is tungsten powder, the Fischer particle size is 0.5 μm, and the purity is greater than 99.9%;

[0031]2) First clean the jet mill equipment, turn on the main control to preheat for 10-30 minutes, fill in high-purity nitrogen with a purity greater than 99.9%, start the grinding valve, adjust the grinding pressure to 0.6Mpa, add raw tungsten powder into the grinding chamber to deagglomerate, and Adjust the frequency of the sorting wheel to 50Hz. After collecting all the powder, repeat the above operation to obtain a jet mill treatment powder.

[0032] 3) The jet milled powder is heated up to 400°C at a rate of 5°C / min in a high-purity hydrogen atmosphere with a purity greater than 99.9%, and kept for 60 minutes, and then calcined twice to eliminate the internal stress generated during the jet milling process ;

[0033] 4) The calcined powder is mixed with an organic binder (microcrystalline wax is 55%, polyethylene wax is 6%, linear low densit...

Embodiment 3

[0037] 1) The raw material powder is tungsten powder, the Fischer particle size is 0.8μm, and the purity is greater than 99.9%;

[0038] 2) First clean the jet mill equipment, turn on the main control to preheat for 10 to 30 minutes, fill in high-purity nitrogen with a purity greater than 99.9%, start the grinding valve, adjust the grinding pressure to 0.7Mpa, add raw tungsten powder into the grinding chamber to deagglomerate, and Adjust the frequency of the sorting wheel to 60Hz. After collecting all the powder, repeat the above operation to obtain three jet milling powders;

[0039] 3) The jet-milled powder is heated up to 500°C at 5°C / min in a high-purity hydrogen atmosphere with a purity greater than 99.9%, kept at a temperature of 100min, and calcined three times to eliminate the internal stress generated during the jet-milling process;

[0040] 4) The calcined powder is mixed with an organic binder (microcrystalline wax is 60%, polyethylene wax is 3%, linear low density ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com