Preparation and use method of polyphenol-polyethylene glycol-based eutectic adhesive

A polyethylene glycol-based, polyethylene glycol technology, which is applied in the field of preparation of polyphenol-polyethylene glycol-based eutectic adhesives, can solve the problems of reduced adhesion strength, limitation, loss, etc., and achieves adhesion speed Fast, fast adhesion, wide range of applied materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The preparation steps of polyphenol-polyethylene glycol-based deep eutectic adhesive are as follows:

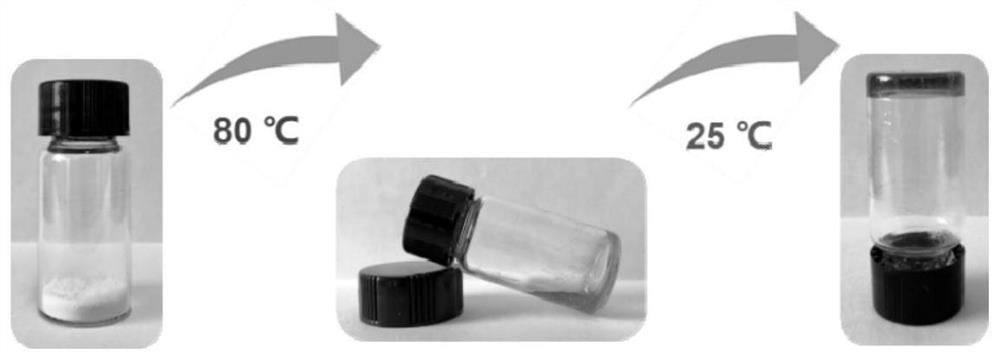

[0057] Mix 1.7g of tannic acid (TA) and 1.3g of linear polyethylene glycol (PEG) powder with a molecular weight of 4kDa in a mortar, then transfer it to a 10mL screw bottle, and carry out at 80°C. Heated in a water bath for 10 minutes and stirred several times to obtain a deep eutectic adhesive. Finally, the obtained eutectic adhesive was placed in a vacuum drying pump for 24 h to remove the air bubbles inside. The preparation process is as figure 1 shown.

Embodiment 2

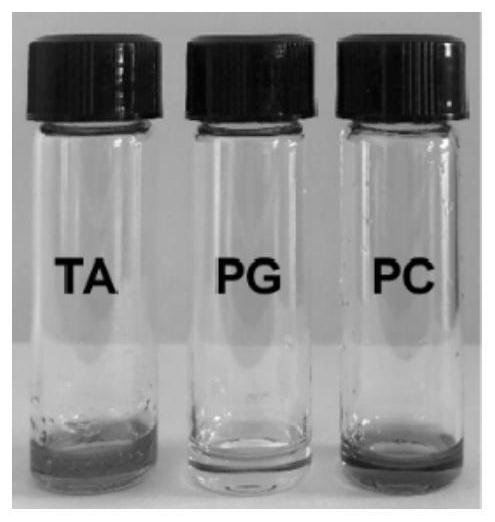

[0059] With the preparation method described in Example 1, the difference is that pyrogallol (PG) and catechol (PC) are used to replace tannic acid respectively; for the eutectic adhesives prepared by different polyphenols, see figure 2 .

Embodiment 3

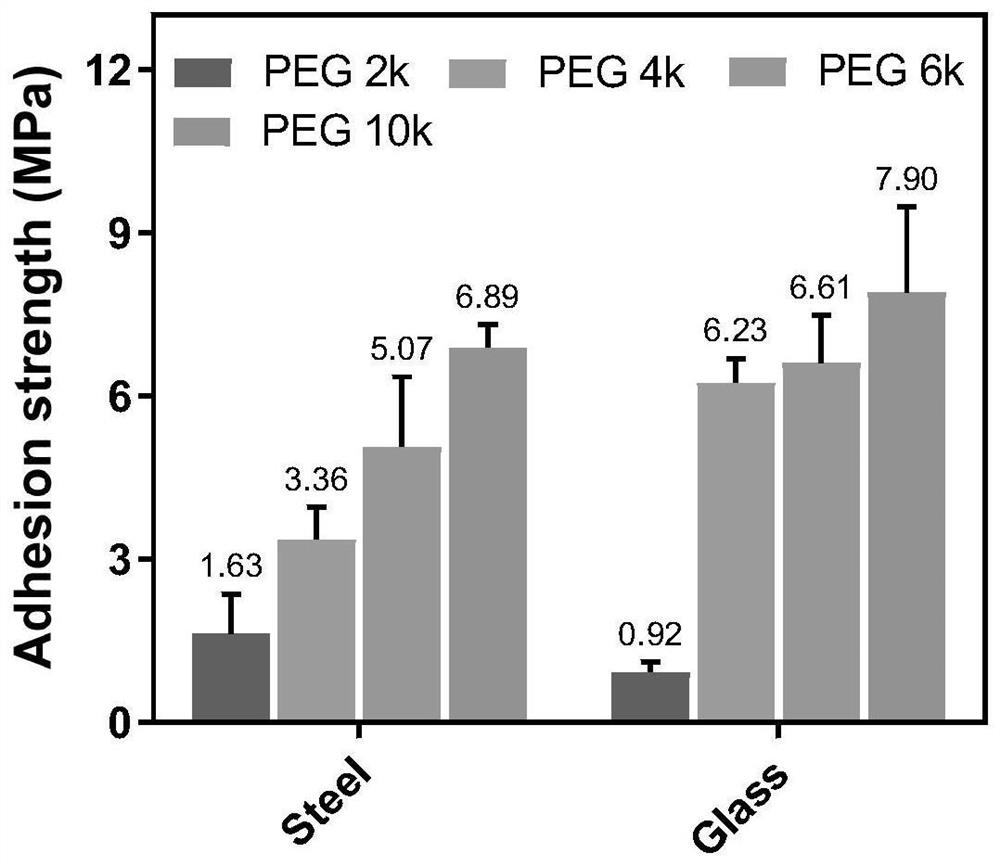

[0061] The same as the preparation method described in Example 1, except that polyethylene glycol with a molecular weight of 2, 6 and 10 kDa is used instead of polyethylene glycol with a molecular weight of 4 kDa.

[0062] Comparison of adhesion strength of eutectic adhesives with different PEG molecular weights image 3 As shown, it can be seen that the adhesion strength of the eutectic adhesive is the highest when the molecular weight of PEG is 10kDa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com