Preparation method of functionalized graphite flake compound

A compound and fossil technology, applied in the fields of carbon compounds, chemical instruments and methods, graphite, etc., can solve the problems of time-consuming and difficult to realize the operation process, and achieve the effect of improving density and high-sensitivity detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this example, graphite powder and pyrenebutyric acid were used as raw materials to prepare carboxyl-functionalized graphite sheet by ultrasonic stripping method, and then amino-functionalized graphite sheet composite was prepared with polyethyleneimine. The specific steps are as follows:

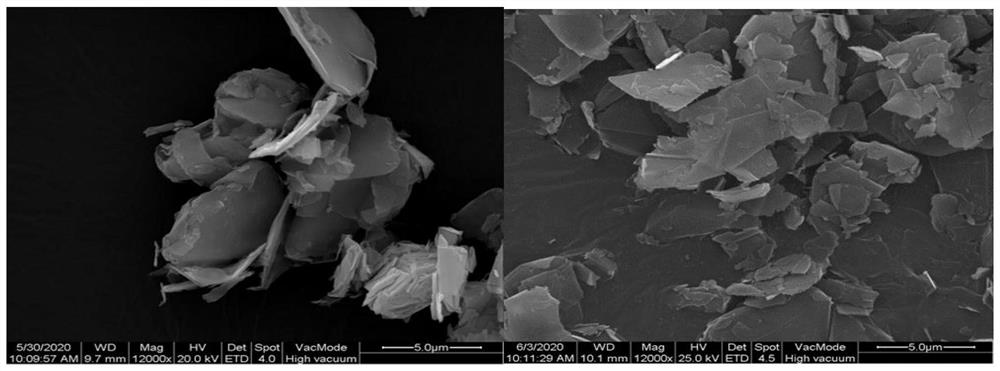

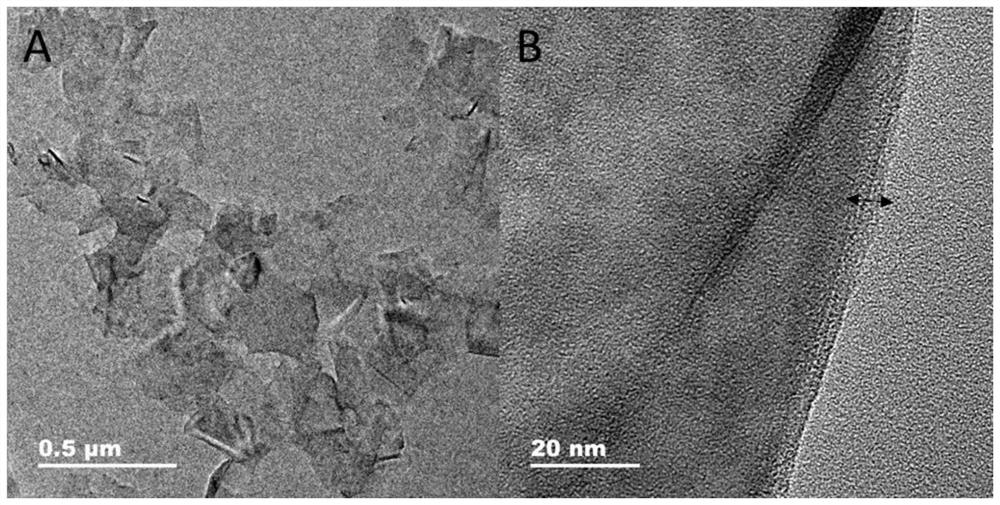

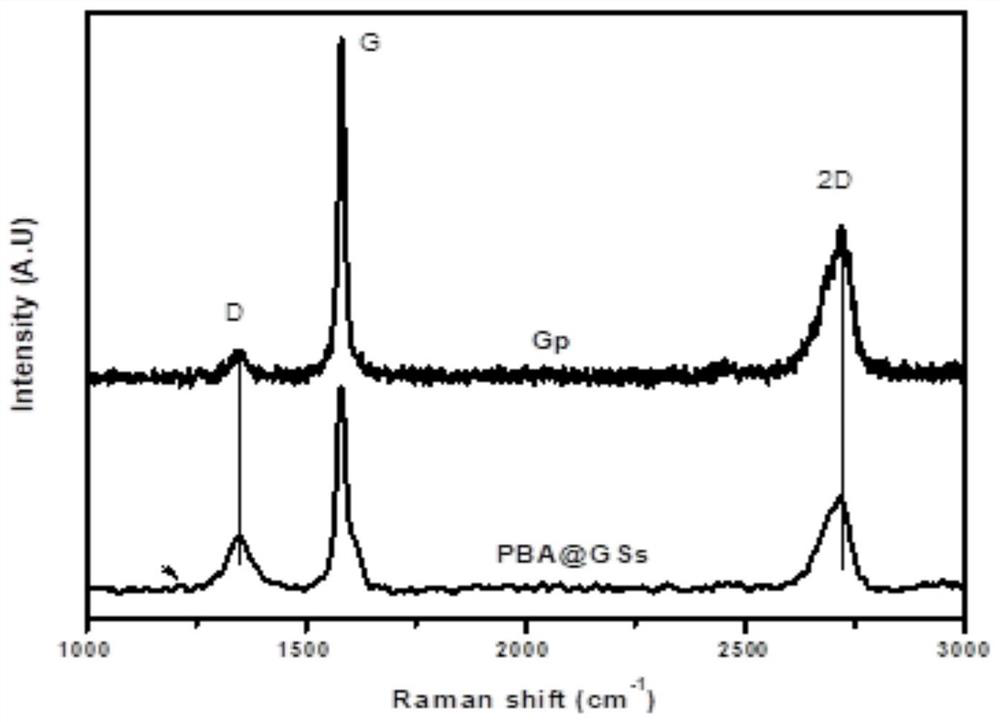

[0037] Step 1: Weigh 40 mg of pyrenebutyric acid (PBA) and add it to 50 mL of DMF, dissolve it by ultrasonication, then add 600 mg of graphite powder (1200 mesh) to it, use an ultrasonic cell pulverizer for continuous ultrasonication for 7 hours (power 25W), and then Speed centrifugation for 5 minutes, take the upper suspension, and then centrifuge at 9000rpm for 20 minutes, and wash the precipitate twice with DMF and deionized water respectively, put it in a vacuum drying oven at 60°C and dry it to obtain carboxyl-functionalized graphite flakes, record for PBA@GSs. The morphology of graphite was observed by scanning electron microscopy.figure 1 It can be seen from the left pictu...

Embodiment 2

[0040] In this example, graphite powder and pyrene formaldehyde were used as raw materials to prepare aldehyde-based functionalized graphite sheets by ultrasonic stripping method, and then amino-functionalized graphite sheet composites were prepared with hexamethylenediamine. The specific steps are as follows:

[0041] Step 1: Weigh 60 mg of pyrene formaldehyde (PyCHO) and dissolve it in 30 mL of DMF, then add 500 mg of graphite powder (1200 mesh) to it, then place it in an ultrasonic cell pulverizer for continuous ultrasonication for 7 hours (power 25W), and then centrifuge at 500 rpm After 5 minutes, the upper layer suspension was taken, and then centrifuged at 9000 rpm for 15 minutes, and the precipitate was washed twice with DMF and deionized water, and dried at 60°C to obtain aldehyde-functionalized graphite sheets, which were designated as PyCHO@GSs.

[0042] Step 2: Weigh 60 mg of hexamethylenediamine and dissolve it in 30 mL of absolute ethanol, then add 300 mg of PyCHO...

Embodiment 3

[0044] In this example, graphite powder and pyrene formaldehyde were used as raw materials to prepare aldehyde functionalized graphite sheet by ultrasonic stripping method, and then made amino functionalized graphite sheet composite with hexamethylenediamine, and then mixed with methyl vinyl ether-maleic anhydride Copolymer reaction, the anhydride-based functionalized graphite flake composite is obtained, and the specific steps are as follows:

[0045] Step 1: Weigh 60 mg of pyrene formaldehyde (PyCHO) and dissolve it in 30 mL of DMF, then add 500 mg of graphite powder (1200 mesh) to it, then place it in an ultrasonic cell pulverizer for continuous ultrasonication for 7 hours (power 25W), and then centrifuge at 500 rpm After 5 minutes, the upper layer suspension was taken, and then centrifuged at 9000 rpm for 15 minutes, and the precipitate was washed twice with DMF and deionized water, and dried at 60°C to obtain aldehyde-functionalized graphite sheets, which were designated a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com