Wide-temperature aluminum electrolytic capacitor and preparation method thereof

A technology of aluminum electrolytic capacitors and capacitors, applied in the field of capacitors, can solve problems such as drop in withstand voltage, increase in leakage current, and drop in capacity, and achieve the effects of reducing power loss and inherent inductance, reducing equivalent series resistance, and large riveting area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

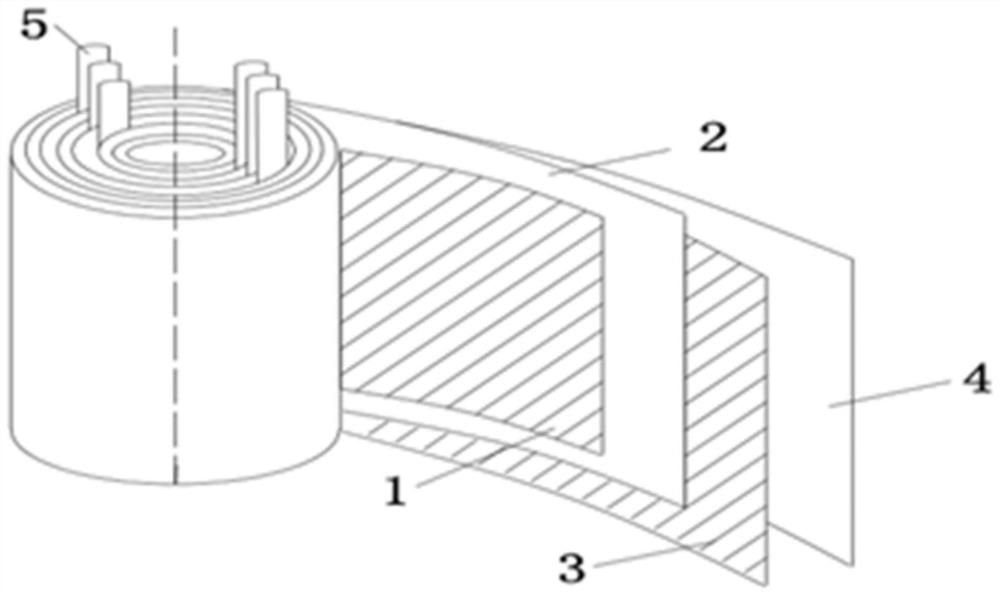

Image

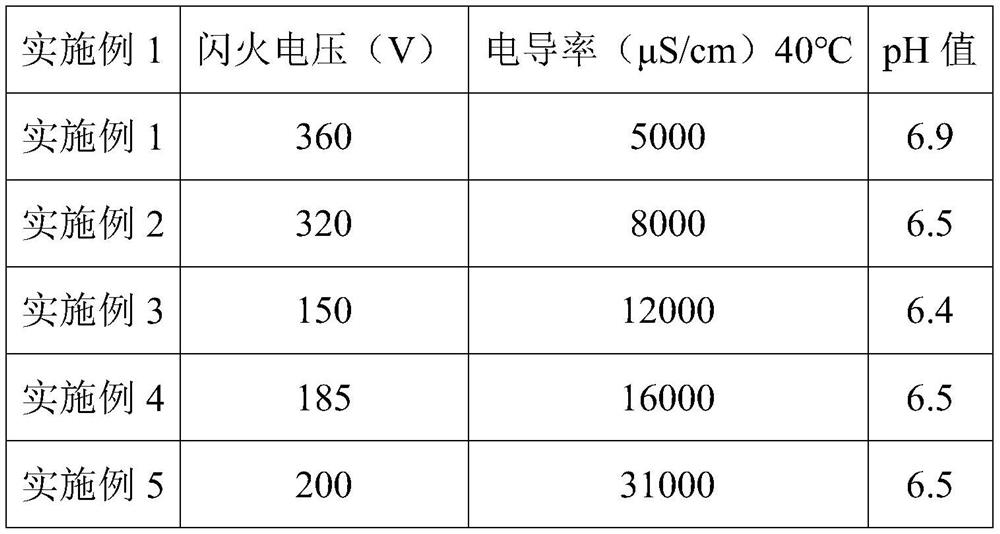

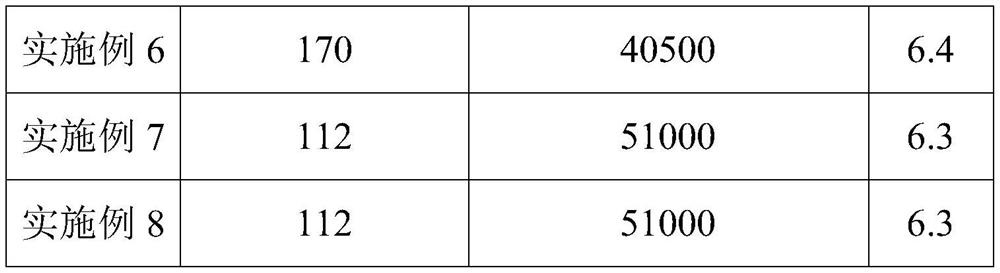

Examples

Embodiment 1

[0036] Electrolyte weight ratio composition:

[0037] Main solvent: Ethylene glycol 82.9%

[0038] Main solute: ammonium adipate 12% ammonium formate 3%

[0039] Additives: p-nitrobenzoic acid 1.5%, citric acid 0.3%, ammonium hypophosphite 0.3%

Embodiment 2

[0041] Electrolyte weight ratio composition:

[0042] Main solvent: ethylene glycol 41.5% Auxiliary solvent: N,N-dimethylformamide 41.4%

[0043] Main solute: ammonium adipate 12% ammonium formate 3%

[0044] Additives: p-nitrobenzoic acid 1.5%, citric acid 0.3%, ammonium hypophosphite 0.3%

Embodiment 3

[0046] Electrolyte weight ratio composition:

[0047] Main solvent: γ-butyrolactone 49.7% Auxiliary solvent: N,N-dimethylformamide 33.2%

[0048] Main solute: ammonium adipate 12% ammonium formate 3%

[0049] Additives: p-nitrobenzoic acid 1.5%, citric acid 0.3%, ammonium hypophosphite 0.3%

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com