Method for preparing formamidino FAPbI3 perovskite solar cell through one-step method at low and medium temperature in air and application of formamidino FAPbI3 perovskite solar cell

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as poor phase stability, and achieve the effects of low cost, high conversion efficiency, and uniform crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Present embodiment is that ionic liquid methylamine acetate (MAAc) of the present invention is used as solvent to prepare formamidine base FAPbI at low temperature in air 3 A planar heterojunction perovskite solar cell is placed upright in order to fully understand the present invention. It mainly includes the following steps:

[0048] Step 1) Weigh 281.6mg of lead iodide and 81.5mg of iodoformamidine, and dissolve the two in 1ml of MAAc solvent.

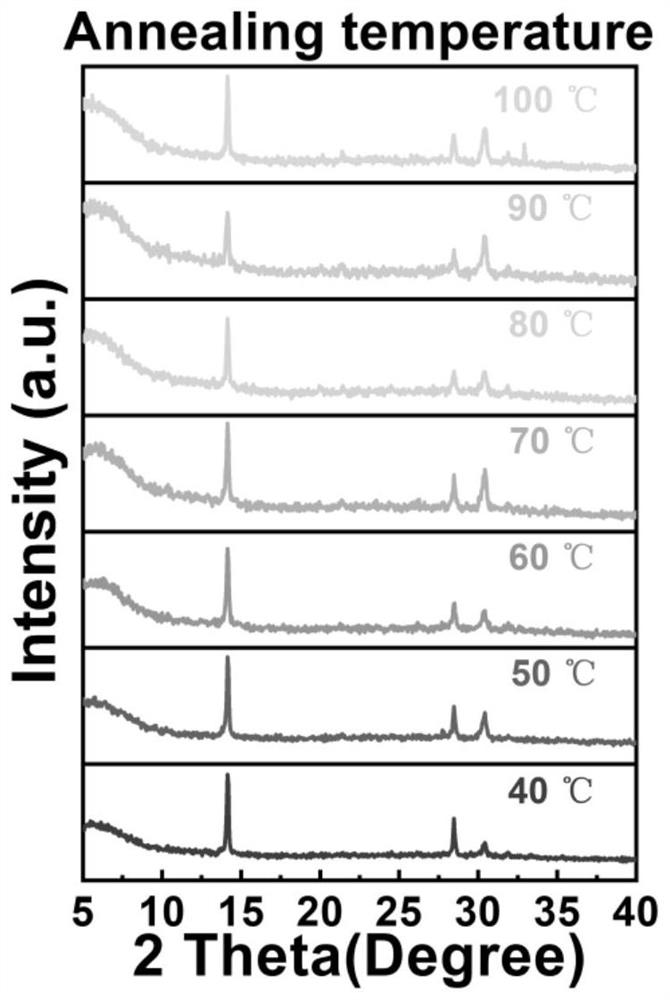

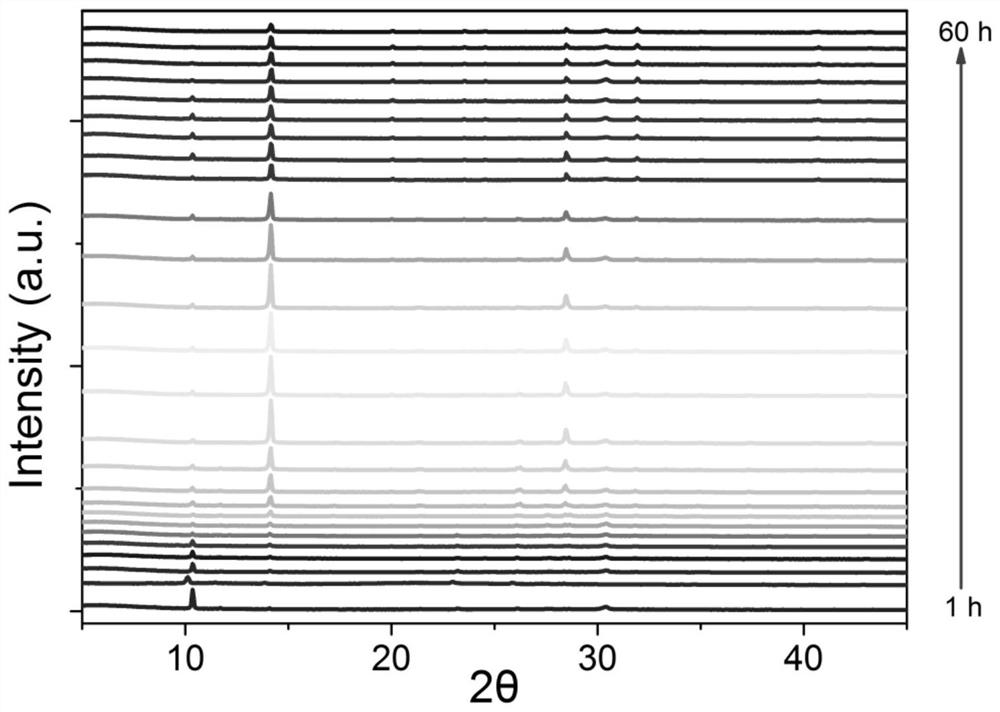

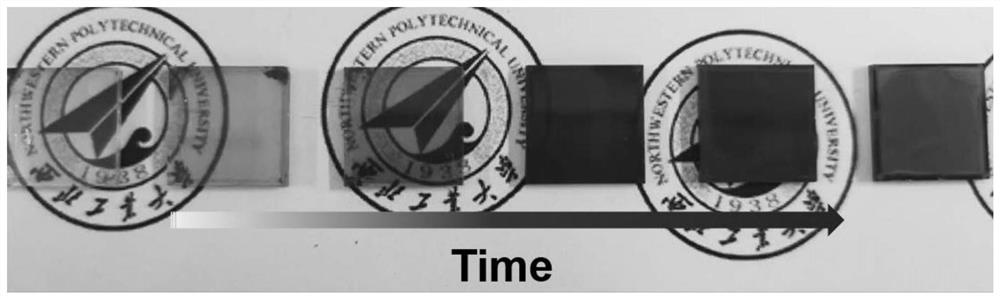

[0049] Step 2) React the precursor solution prepared in step 1) at 90° C. for 36 hours, with precise temperature and time control.

[0050] Step 3) Cleaning the ITO conductive glass, the sequence is ethanol, ultrapure water, adding cleaning agent, ultrapure water, acetone, and ethanol, respectively, sonicating for 10 minutes. And blow dry with nitrogen to obtain a clean conductive glass substrate.

[0051] Step 4) Treat the cleaned ITO substrate in step 2) with ultraviolet and ozone for 15 minutes.

[0052] Step 5) Take S...

Embodiment 2

[0065] Present embodiment is that ionic liquid methylamine acetate (MAAc) of the present invention is used as solvent to prepare formamidine base FAPbI at low temperature in air 3 Inverted planar heterojunction perovskite solar cell for a full understanding of the invention. It mainly includes the following steps:

[0066] Step 1) Weigh 281.6mg of lead iodide and 81.5mg of iodoformamidine, and dissolve the two in 1ml of MAAc solvent.

[0067] Step 2) React the precursor solution prepared in step 1) at 90° C. for 36 hours, with precise temperature and time control.

[0068] Step 3) Cleaning the ITO conductive glass, the sequence is ethanol, ultrapure water, adding cleaning agent, ultrapure water, acetone, and ethanol, respectively, sonicating for 10 minutes. And blow dry with nitrogen to obtain a clean conductive glass substrate.

[0069] Step 4) Treat the cleaned ITO substrate in step 2) with ultraviolet and ozone for 15 minutes.

[0070] Step 5) Take NiOx 10mg and complet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com