Magnetor coupling resonance type micro-nano weighing device and preparation method thereof

A technology of coupling resonance and magnons, which is applied to the parts of magnetostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, device parts, etc., can solve the problems of large environmental impact and achieve absorption bandwidth change narrower, improved measurement accuracy, and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

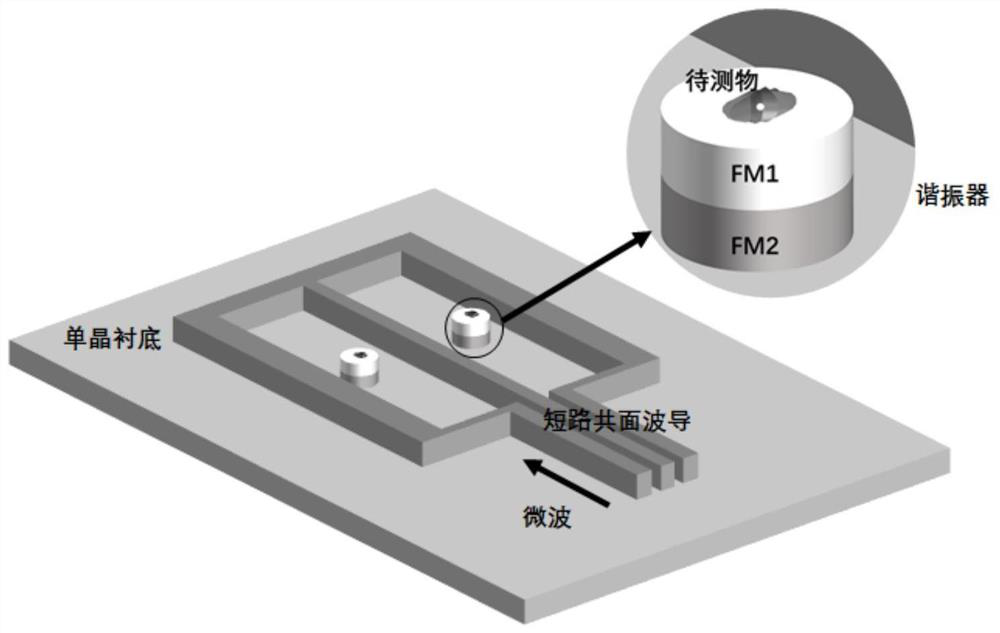

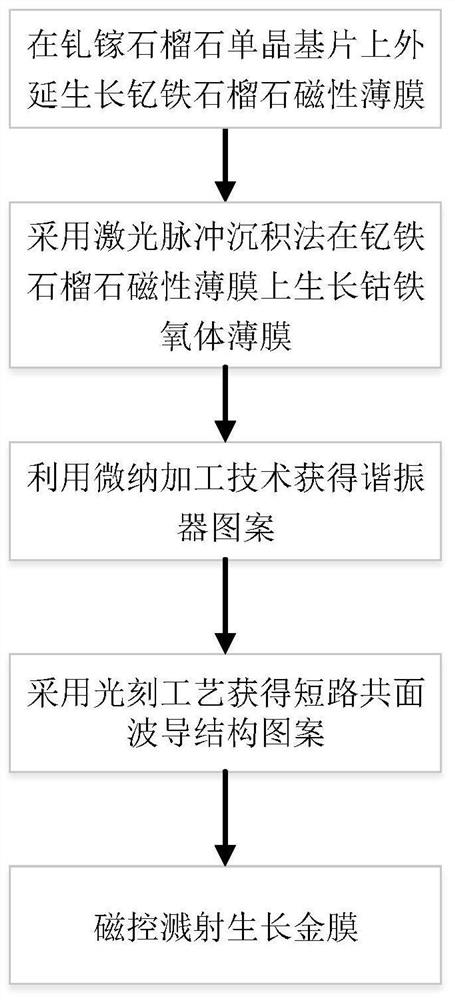

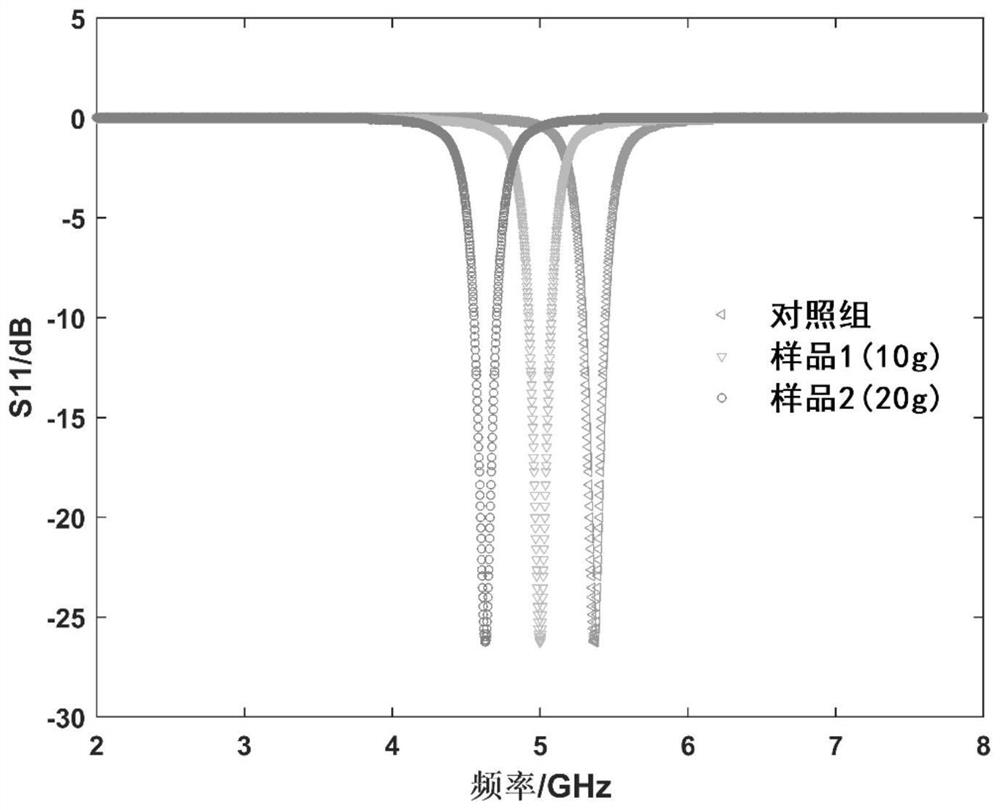

[0037] This embodiment proposes a magnon-coupled resonance micro-nano weighing device with a structure such as figure 1 As shown, including the [111] crystal orientation of the GdGaGa single crystal substrate and the short-circuited coplanar waveguide and resonator on the GdGaGa single-crystal substrate, the resonator is located in the center zone and the ground zone of the short-circuited coplanar waveguide between; the resonator is a double-layer film structure, including an upper layer of cobalt ferrite (CFO) film and a lower layer of yttrium iron garnet magnetic film;

[0038] Among them, the thickness of the cobalt ferrite film is 1 μm; the thickness of the yttrium iron garnet magnetic film is 1 μm; the overall structure of the resonator is cylindrical with a diameter of 1 mm; The characteristic impedance of the coplanar waveguide is 50 ohm, the width of the central strip and the ground strip is 50 μm, and the width of the waveguide at the short-circuit end is 70 μm.

[...

Embodiment 2

[0054] This embodiment proposes a magnon-coupled resonance micro-nano weighing device, including a [111] oriented gadolinium-gallium garnet single crystal substrate and a short-circuit coplanar waveguide and resonance on the gadolinium-gallium garnet single-crystal substrate. The resonator is located between the center strip and the grounding strip of the short-circuit coplanar waveguide; the resonator is a double-layer film structure, including an upper layer of FeGa alloy film and a lower layer of yttrium iron garnet magnetic film;

[0055] Among them, the thickness of the FeGa alloy film is 1 μm; the thickness of the yttrium iron garnet magnetic film is 1 μm; the overall structure of the resonator is cylindrical with a diameter of 1 mm; The characteristic impedance of the waveguide is 50 ohm, the width of the center strip and the ground strip is 50 μm, and the width of the waveguide at the short-circuit end is 70 μm.

[0056] This embodiment also proposes a method for prepa...

Embodiment 3

[0064] This embodiment proposes a magnon-coupled resonance micro-nano weighing device, including a [111] oriented gadolinium-gallium garnet single crystal substrate and a short-circuit coplanar waveguide and resonance on the gadolinium-gallium garnet single-crystal substrate. The resonator is located between the center strip and the ground strip of the short-circuit coplanar waveguide; the resonator is a double-layer film structure, including the upper layer of Fe 30 co 70 alloy thin film and the underlying yttrium iron garnet magnetic thin film;

[0065] Among them, Fe 30 co 70 The thickness of the alloy film is 1 μm; the thickness of the yttrium iron garnet magnetic film is 1 μm; the overall structure of the resonator is cylindrical, with a diameter of 1 mm; the material of the short-circuit coplanar waveguide is gold, and the thickness is 2 μm. The characteristics of the short-circuit coplanar waveguide The impedance is 50 ohm, the width of the central strip and the grou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com