Preparation method of TiB2 powder

A system and powder technology, which is applied in the field of TiB2 powder preparation, can solve the problems of unfavorable material properties, long production cycle, easy powder agglomeration, etc., and achieve the effect of short synthesis time, high heating efficiency and low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

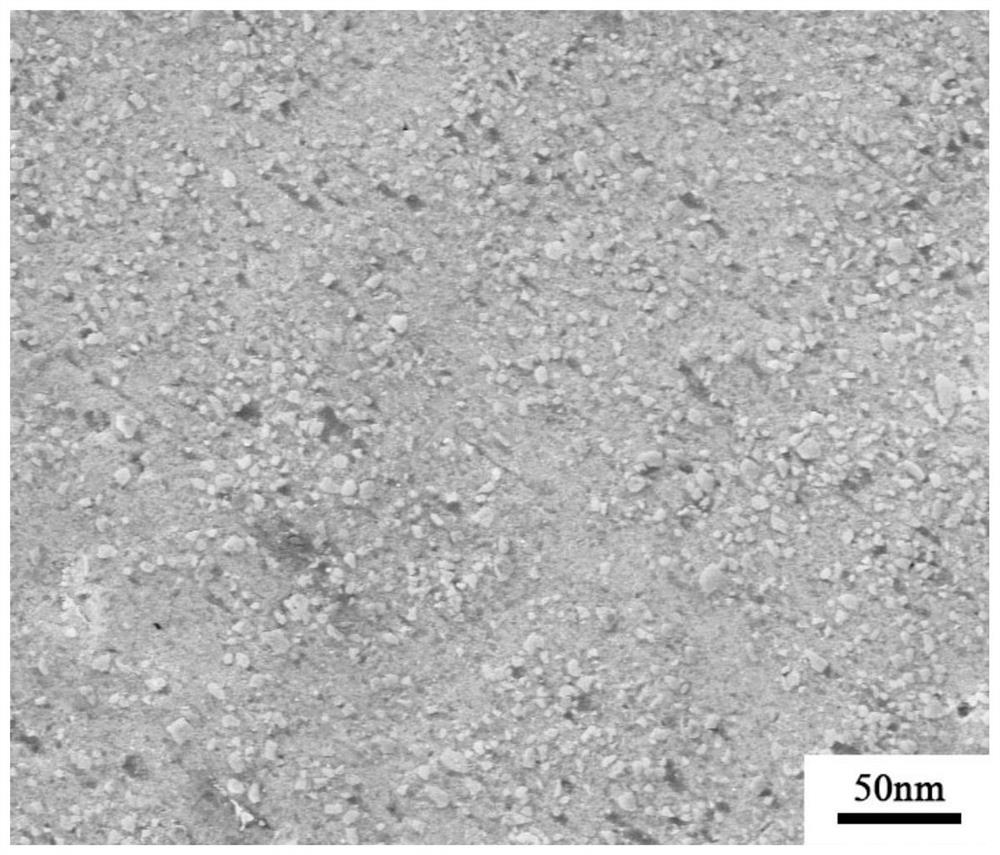

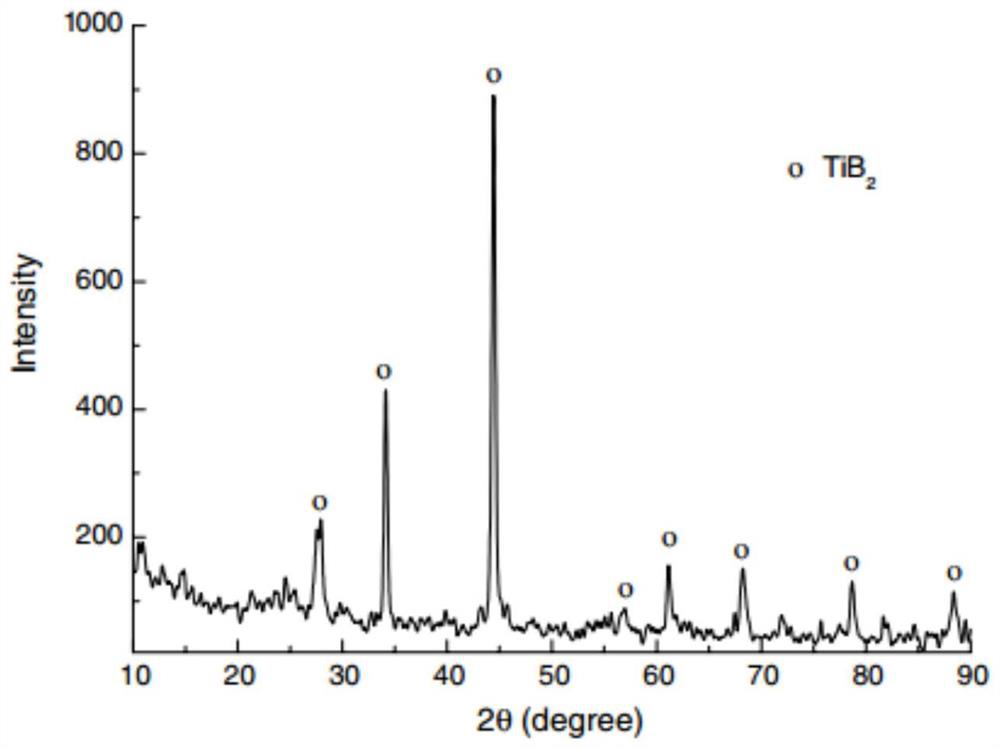

Image

Examples

Embodiment 1

[0034] (1) Configure boric acid mixed solution: press H 3 BO 3 (boric acid) and Ti(OC 4 h 9 ) 4 The boron-titanium molar ratio of (butyl titanate) is 4:1 and takes by weighing 2.472g H 3 BO 3 , press C 12 h 22 o 11 The carbon-titanium molar ratio of (sucrose) and butyl titanate is 6:1 and takes 1.71g C 12 h 22 o 11 , the H 3 BO 3 with C 12 h 22 o 11 Mix to get a mixture, add 10ml C to the mixture 2 h 5 OH (ethanol), heated to 70 ° C and stirred until the mixture was completely dissolved to obtain a mixed solution with a boric acid concentration of 4 mol / L, which was solution A;

[0035] (2) Configure organic titanium mixed solution: according to H 3 BO3 with Ti(OC 4 h 9 ) 4 The boron-titanium molar ratio is 4:1 and weighs 3.399gTi(OC 4 h 9 ) 4 ; Weigh 1.4g C 5 h 8 o 2 (acetylacetone), the C 5 h 8 o 2 Slowly added to the stirring Ti(OC 4 h 9 ) 4 In the organic titanium mixed solution is formed, which is solution B;

[0036] (3) Preparation of b...

Embodiment 2

[0042] (1) Configure boric acid mixed solution: press H 3 BO 3 with Ti(OC 4 h 9 ) 4 The boron-titanium molar ratio is 3.5:1 and weighs 2.163gH 3 BO 3 , press C 12 h 22 o 11 with Ti(OC 4 h 9 ) 4 The molar ratio of carbon to titanium is 5:1 to take 1.42g C 12 h 22 o 11 , the H 3 BO 3 with C 12 h 22 o 11 Mix to get a mixture, add 10ml C to the mixture 2 h 5 OH, heated to 70°C and stirred until the mixture was completely dissolved to obtain a mixed solution with a boric acid concentration of 4mol / L, which was solution A;

[0043] (2) Configure organic titanium mixed solution: according to H 3 BO 3 with Ti(OC 4 h 9 ) 4 The boron-titanium molar ratio is 4:1 and weighs 3.399gTi(OC 4 h 9 ) 4 ; Weigh 1.36g C 5 h 8 o 2 , the C 5 h 8 o 2 Slowly added to the stirring Ti(OC 4 h 9 ) 4 In the organic titanium mixed solution is formed, which is solution B;

[0044] (3) Preparation of boron-titanium mixed sol: put solution A in an ultrasonic stirrer, pour ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com