Application of zinc titanate in crystalline silicon solar cell

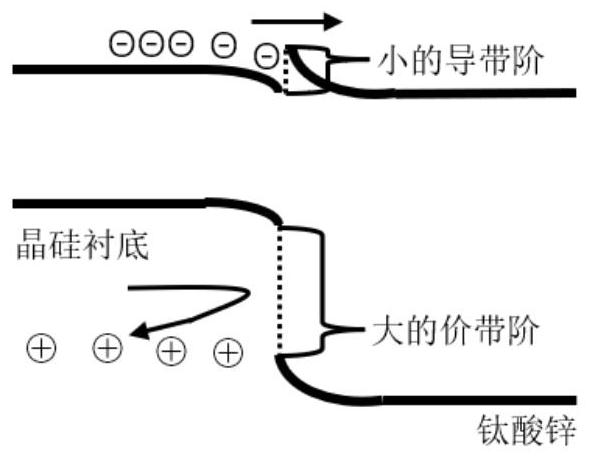

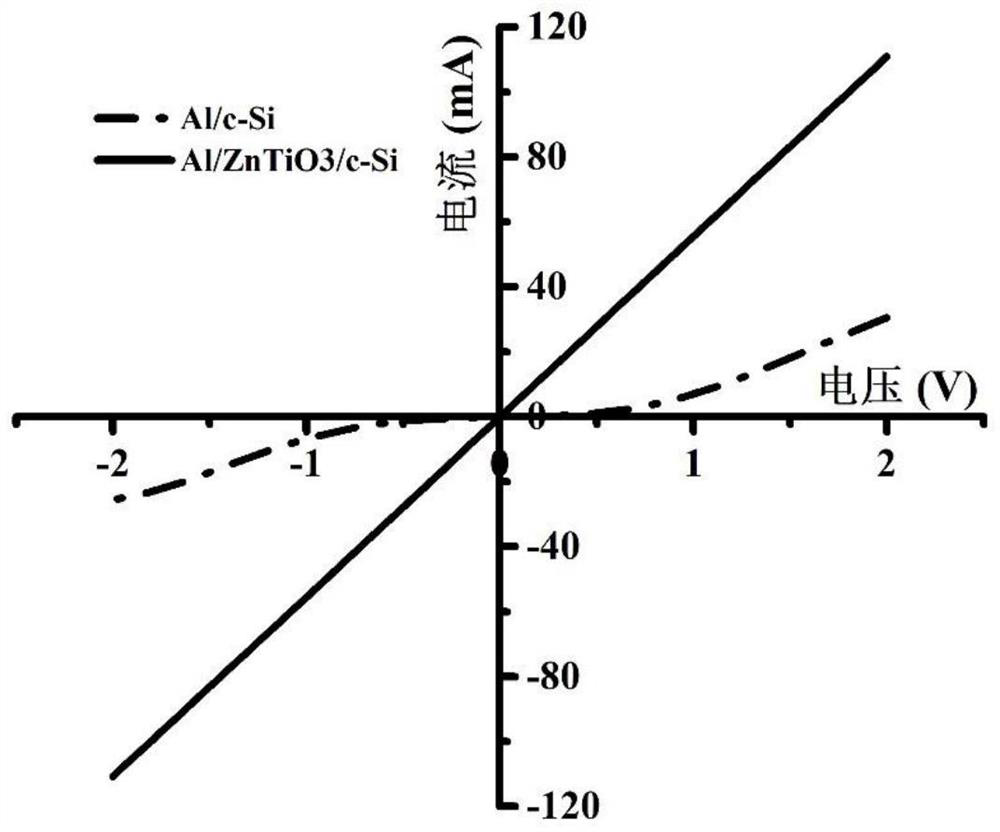

A technology of crystalline silicon solar cells and zinc titanate, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reducing device photogenerated current, narrow density band gap, and restricting spectral response, so as to increase photogenerated current and reduce Effect of parasitic absorption, good carrier transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

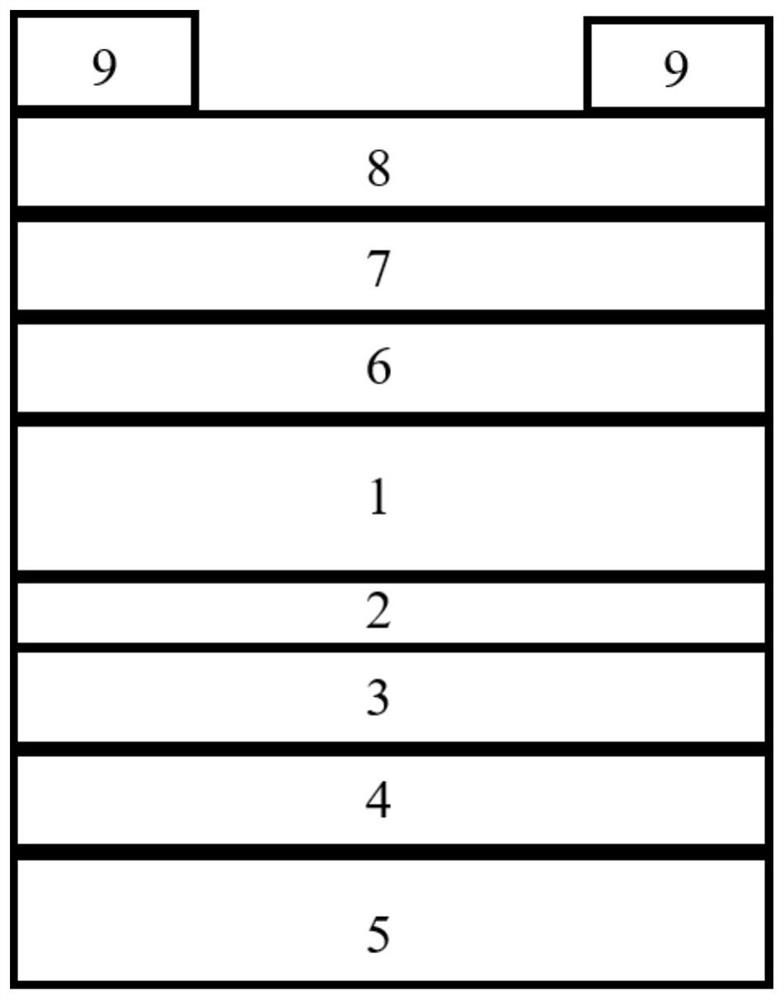

[0034] The schematic diagram of the structure of the crystalline silicon solar cell prepared in this example is shown in figure 2 ,in:

[0035] 1 is a crystalline silicon substrate, specifically an N-type crystalline silicon substrate (P-type has the same technical effect), with a thickness of 300 μm;

[0036] 2 is the lower passivation film, covering the entire lower surface of the crystalline silicon substrate, with a thickness of 10nm;

[0037] 3 is a zinc titanate electron selective layer covering the entire lower passivation film with a thickness of 100nm;

[0038] 4 is the lower transparent conductive film, covering the entire zinc titanate electron selective layer, with a thickness of 80nm;

[0039] 5 is the lower metal electrode layer, covering the entire lower transparent conductive film, with a thickness of 500nm;

[0040] 6 is an upper passivation film layer, covering the entire upper surface of the crystalline silicon substrate, with a thickness of 10nm;

[00...

Embodiment 2

[0053] (1) Pretreat the P-type crystalline silicon substrate by wet chemical method, including polishing, cleaning, and texturing; the specific steps are as follows: first, the silicon wafer is put into a NaOH solution with a concentration of 10%. Wash at ℃ for 15 minutes to remove the damaged layer of the silicon wafer, that is, to polish; secondly, put the silicon wafer with the damaged layer in 3% KOH alkali solution for 10 minutes, and use the alkali solution to etch different crystal faces The difference in speed is used for random pyramid texturing on the surface to form randomly distributed pyramid textures; finally, the RCA cleaning process is used to put the silicon wafer into a mixed aqueous solution of hydrochloric acid and hydrogen peroxide, and the solution ratio is HCl:H 2 o 2 :H 2 O=1:1:5, temperature 80°C, soak for 10min to remove metal ions.

[0054] (2) Use plasma enhanced chemical vapor deposition (PECVD) to SiH 4 、H 2 As a reaction gas, an intrinsic hyd...

Embodiment 3

[0061] (1) N-type crystalline silicon substrate is pretreated by wet chemical method, including polishing, cleaning, and texturing; the specific steps are as follows: first, the silicon wafer is put into a NaOH solution with a concentration of 10%. Wash at ℃ for 15 minutes to remove the damaged layer of the silicon wafer, that is, to polish; secondly, put the silicon wafer with the damaged layer in 3% KOH alkali solution for 10 minutes, and use the alkali solution to etch different crystal faces The difference in speed is used for random pyramid texturing on the surface to form randomly distributed pyramid textures; finally, the RCA cleaning process is used to put the silicon wafer into a mixed aqueous solution of hydrochloric acid and hydrogen peroxide, and the solution ratio is HCl:H 2 o 2 :H 2 O=1:1:5, temperature 80°C, soak for 10min to remove metal ions.

[0062] (2) Use plasma enhanced chemical vapor deposition (PECVD) to SiH 4 、H 2 As a reaction gas, an intrinsic hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com