Carotenoid preparation and application thereof

A carotene and preparation technology, applied in the field of microparticle preparation, can solve the problems of products that have not introduced carotenoid preparations, and achieve the effects of reducing pigment dissolution, improving stability, and making the preparation process green and environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The influence of the processing method of embodiment 1 crystal on crystal stability

[0052] (1) Mix 160g of zeaxanthin crystals with 4 times the amount of 60% ethanol aqueous solution, stir at 45°C for 30min, and then disperse through high-speed shearing at 10,000 rpm, add 28g of ascorbic acid, 10g of ascorbyl palmitate, and 10g of sucrose fatty acid ester. The solvent was removed at 75° C., 8 ppm of ethanol was dissolved, and the water content of the crystal was 12.3%, and zeaxanthin crystal A was obtained.

[0053] (2) Mix 160g of zeaxanthin crystals with 4 times the amount of 60% ethanol aqueous solution, stir at 45°C for 30min, then disperse at 10,000 rpm with high-speed shear, add 28g of ascorbic acid and 10g of ascorbyl palmitate, and remove the solvent at 75°C. 55ppm of ethanol was dissolved, and the water content of the crystal was 25%, and the crystal B of zeaxanthin was obtained.

[0054] (3) Mix 160g of zeaxanthin crystals with 8 times the amount of 80% eth...

Embodiment 2

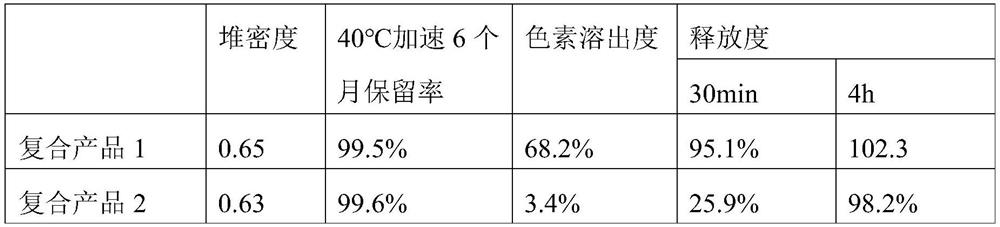

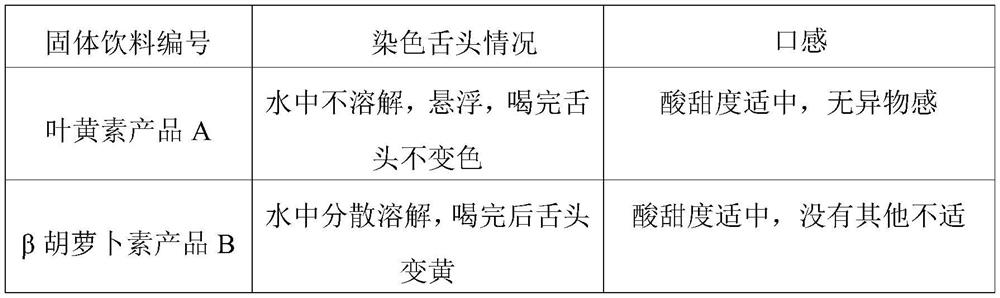

[0061] Mix 200g of lutein crystals with 3 times the amount of 60% ethanol aqueous solution, stir at 45°C for 30min, and then disperse at 10,000 rpm with high-speed shear, add 20g of ascorbic acid, 1g of ascorbyl palmitate, and 1g of sucrose fatty acid ester, and desorb at 75°C. The solvent was removed, 7ppm was dissolved in ethanol, the water content of the crystals was 10%, and the crystals were frozen at -20°C for later use. Prepare 583 g of sodium starch octenyl succinate and 195 g of glucose into an aqueous solution with a solid content of 50%, stir and disperse at 60°C, raise the temperature to 90°C, and stir at a constant speed for 35 minutes. Cool down to 60°C and stir for 100min. The gelatinized wall material and the treated lutein crystals are mixed, stirred, emulsified and spray-dried. The lutein product A was obtained, its pigment dissolution rate was 3.1%, and its 30min and 4h release rates were 30.5% and 103.3%. The release rate at different times is shown in th...

Embodiment 3

[0065] Mix 233g of β-carrot crystals with 5 times the amount of 50% ethanol aqueous solution, stir at 40°C for 40min, then disperse at 10,000 rpm with high-speed shear, add 17g of ascorbic acid, 25.5g of ascorbyl palmitate, 25.5g of sucrose fatty acid ester, and heat at 70°C The solvent was removed, 5 ppm of ethanol was dissolved, the water content of the crystals was 15%, and the crystals were frozen at -20°C for later use. Prepare 560 g of sodium starch octenyl succinate and 140 g of glucose into an aqueous solution with a solid content of 70%, stir and disperse at 50°C, raise the temperature to 80°C, and stir at a constant speed for 50 minutes. Cool down to 65°C and stir for 120min. The gelatinized wall material and the treated lutein crystals are mixed, stirred, emulsified and spray-dried. The beta carrot product A was obtained, its pigment dissolution rate was 2.3%, and its 30min and 4h release rates were 28.3% and 100.2%. The release rate at different times is shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com