Surface amination modification method of quartz sand filter material for biological sand filter

A technology of surface amination and quartz sand, applied in the direction of silicon oxide, silicon dioxide, etc., can solve the problems of low graft conversion rate and great influence on the grafting process, achieve good dispersion, avoid local agglomeration, and ensure uniformity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

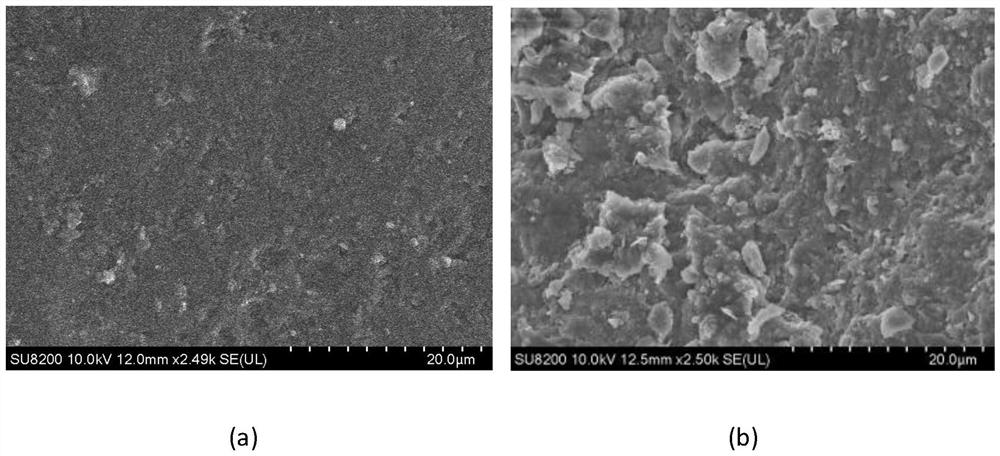

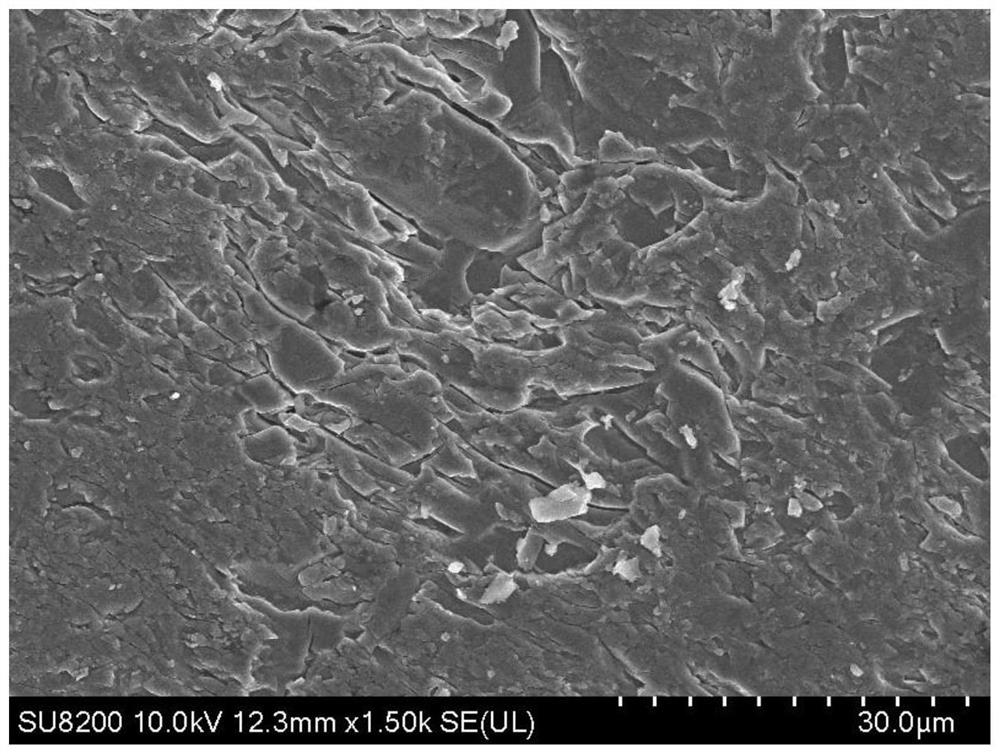

Image

Examples

Embodiment 1

[0038] This embodiment provides a method for surface amination modification of a quartz sand filter material for a biological sand filter, which includes the following steps:

[0039] (1) Pretreatment: take 45g of quartz sand and treat it with acetone, and then soak it in 3M sodium hydroxide solution for 12 hours, so that a large amount of hydroxyl groups are generated on the surface of the quartz sand; take out the quartz sand and rinse it twice with ethanol, and dry it at 60°C. Hydroxylated quartz sand is obtained.

[0040](2) Prepare the grafting agent solution: mix n-butanol: ammonia water (28wt%): pure water in a volume ratio of 8:1:1, and disperse ultrasonically for 20 minutes to obtain 30 mL of mixed solvent; add 1 mg of polyethylene glycol to the mixed solvent Alcohol (molecular weight is 4000), after fully stirring 30min, add 9g silane coupling agent KH550 again, continue to stir, make grafting agent solution;

[0041] (3) Graft modification: mix the hydroxylated qua...

Embodiment 2

[0047] This embodiment provides a method for surface amination modification of a quartz sand filter material for a biological sand filter, which includes the following steps:

[0048] (1) Pretreatment: take 45g of quartz sand and treat it with acetone, and then soak it in 10M sodium hydroxide solution for 10 hours, so that a large amount of hydroxyl groups are generated on the surface of the quartz sand; take out the quartz sand and rinse it twice with ethanol, and dry it at 60°C. Hydroxylated quartz sand is obtained.

[0049] (2) Prepare the grafting agent solution: mix n-butanol: ammonia water (30wt%): pure water in a volume ratio of 8:1:1, and disperse ultrasonically for 20 minutes to obtain 35 mL of mixed solvent; add 1.2 mg of polyethylene glycol to the mixed solvent Diol (molecular weight is 4000), after fully stirring 30min, add 9g silane coupling agent KH550 again, continue to stir, make grafting agent solution;

[0050] (3), grafting modification: mix the hydroxylate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com