Mud-resistant water-retention polycarboxylic acid water reducing agent for machine-made sand concrete and preparation method of mud-resistant water-retention polycarboxylic acid water reducing agent

A technology for concrete and machine-made sand, applied in the field of building admixtures, can solve the problems of insufficient anti-mud and water-retaining properties of water-reducing agents, and achieve the effects of improving water-retaining effect, enhancing adhesion ability, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

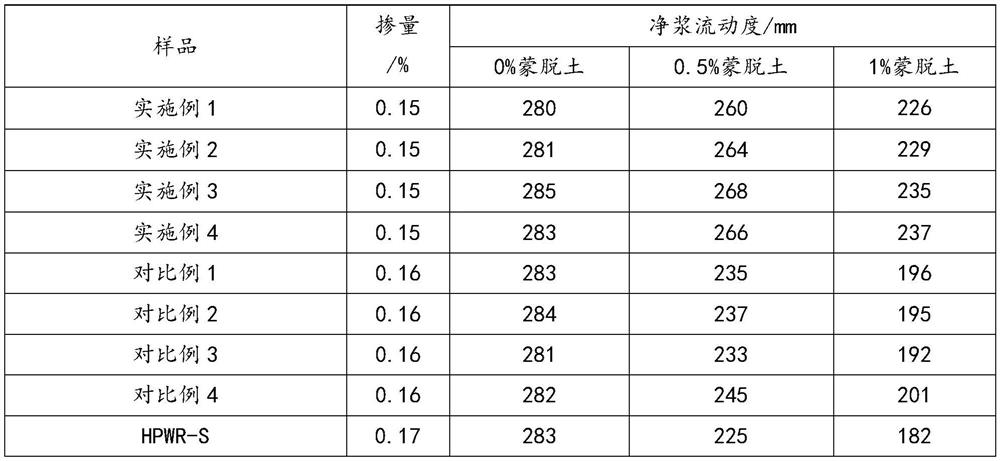

Examples

Embodiment 1

[0047] (1) Preparation of caffeic acid-γ-cyclodextrin unsaturated esterification monomer: 100 parts of caffeic acid, 50 parts of γ-cyclodextrin, 1.5 parts of toluenesulfonic acid, 0.75 parts of N-nitroso-N- Phenylhydroxylamine aluminum and 15 parts of petroleum ether are added to a microwave reactor, heated to 100°C under 200W microwave power, and reacted for 70 minutes to obtain caffeic acid-γ-cyclodextrin unsaturated esterified monomer;

[0048] (2) Copolymerization: 85 parts of methoxypolyethylene glycol acrylate, 20 parts of acrylic acid and 20 parts of water are mixed to obtain a monomer mixed aqueous solution; 0.8 parts of ammonium persulfate is mixed with 30 parts of water to obtain an aqueous initiator solution; 1 part of 3-mercaptoacetic acid-2-methylhexyl ester is mixed with 30 parts of water to obtain chain transfer agent aqueous solution;

[0049] Put 1 part of caffeic acid-γ-cyclodextrin unsaturated esterification monomer and appropriate amount of water in a micro...

Embodiment 2

[0052] (1) Copolymerization reaction: Mix 75 parts of methoxypolyethylene glycol methacrylate, 16 parts of methacrylic acid, 3 parts of diethylene glycol diacrylate and 20 parts of water to obtain a monomer mixed aqueous solution; Sodium persulfate was mixed with 30 parts of water to obtain an aqueous initiator solution; 0.8 parts of 2,4-diphenyl-4-methyl-1-pentene was mixed with 30 parts of water to obtain an aqueous chain transfer agent solution;

[0053] Put an appropriate amount of water in a microwave reactor, heat it to 70°C under a microwave power of 300W, and add the monomer mixed aqueous solution, initiator aqueous solution and chain transfer agent aqueous solution dropwise at a constant temperature of 70°C; the addition is completed within 40 minutes The above monomer mixed aqueous solution, initiator aqueous solution and chain transfer agent aqueous solution; after the dropwise addition, continue to react for 30 minutes to obtain a copolymerized product;

[0054] (2...

Embodiment 3

[0056] (1) Preparation of caffeic acid-γ-cyclodextrin unsaturated esterification monomer: 100 parts of caffeic acid, 200 parts of γ-cyclodextrin, 6 parts of sodium bisulfate, 4.5 parts of N, N-dibutyl di Add copper thiocarbamate and 54 parts of toluene into a microwave reactor, heat to 120°C under 500W microwave power, and react for 40 minutes to obtain caffeic acid-γ-cyclodextrin unsaturated esterified monomer;

[0057] (2) Copolymerization reaction: Mix 65 parts of methoxypolyethylene glycol methacrylate, 12 parts of acrylic acid, 1 part of diethylene glycol diacrylate and 30 parts of water to obtain a monomer mixed aqueous solution; Potassium is mixed with 30 parts of water to obtain an aqueous initiator solution; 0.6 parts of 3-mercaptoacetic acid-2-methylhexyl ester is mixed with 30 parts of water to obtain an aqueous chain transfer agent solution;

[0058] Put 4 parts of caffeic acid-γ-cyclodextrin unsaturated esterification monomer and appropriate amount of water in a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com