Preparation method of degradable PET-based copolyester

A technology of copolyester and glycolic acid copolyester, which is applied in the field of preparation of degradable PET-based copolyester, can solve the problems of slow degradation rate of copolyester, poor thermal stability, complicated preparation process, etc., and achieve simple and easy operation line, improve thermal stability, good thermal stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

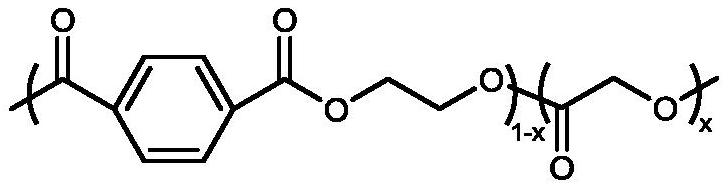

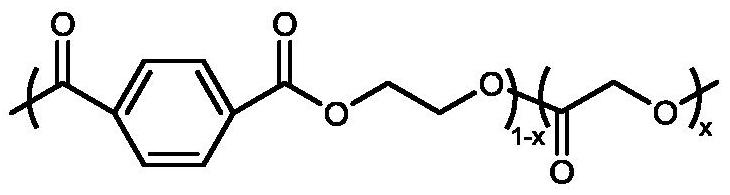

[0029] Introduce rapidly degradable PGA in PET molecular chain, obtain terephthalic acid-ethylene glycol-glycolic acid copolyester P (ET-co-GA), its preparation method comprises the steps:

[0030] 1. One-step melt polycondensation

[0031]Add dimethyl terephthalate, ethylene glycol, glycolic acid, catalyst and stabilizer to the reactor, wherein the molar ratio of ethylene glycol to dimethyl terephthalate is 1-2, glycolic acid and terephthalic acid The molar ratio of dimethyl diformate is 0-0.5; raise the temperature twice under an inert atmosphere, first raise the temperature to 150-190°C, pressurize to 0-0.02MPa, react for 1-3h, then raise the temperature to 200-230°C, React for 1 to 5 hours, carry out the transesterification / esterification reaction, the heating time of the transesterification can be determined according to the discharged small molecules; after the discharge of water or methanol exceeds 80% of the theoretical value, the temperature is raised twice under vacu...

Embodiment 1

[0043] One-step melt polycondensation to obtain P(ET-co-GA-5), x / 1-x=5mol%.

[0044] 500g dimethyl terephthalate, 223.9g ethylene glycol, 9.8g glycolic acid, antimony trioxide of 0.04% of total monomer mass, anhydrous zinc acetate of 0.0175% of total monomer mass and 0.07% of total monomer mass Add tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester into a 2.5L stainless steel polycondensation reactor (Yangzhou Pulit Co., Ltd.), fully replace the reactor with nitrogen In the air, heat the reactor to 160°C, pressurize to 0.01MPa, react for 1h, heat up to 210°C and continue the reaction until the methanol discharge is 40% of the theoretical value, continue to heat up to 230°C, and react for 3h; until methanol After the discharge volume is 80% of the theoretical value, first raise the temperature to 250°C under vacuum, reduce the pressure to 0.066MPa, react for 0.5h, then raise the temperature to 260°C, reduce the pressure to 40Pa, react for 1h, carry o...

Embodiment 2

[0046] One-step melt polycondensation to obtain P(ET-co-GA-10), x / 1-x=10mol%.

[0047] 500g dimethyl terephthalate, 223.9g ethylene glycol, 19.6g glycolic acid, antimony trioxide of 0.04% of total monomer mass, anhydrous zinc acetate of 0.0175% of total monomer mass and 0.07% of total monomer mass Add tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester into a 2.5L stainless steel polycondensation reactor (Yangzhou Pulit Co., Ltd.), fully replace the reactor with nitrogen In the air, heat the reactor to 160°C, pressurize to 0.01MPa, react for 1h, heat up to 210°C and continue the reaction until the methanol discharge is 40% of the theoretical value, continue to heat up to 230°C, and react for 3h; until methanol After the discharge volume is 80% of the theoretical value, first raise the temperature to 250°C under vacuum, reduce the pressure to 0.066MPa, react for 0.5h, then raise the temperature to 260°C, reduce the pressure to 40Pa, react for 1h, carr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com