Processing technology of meat tissue-like concentrated fish protein

A processing technology, fish protein technology, applied in the direction of animal protein processing, fish protein composition, and texturization treatment, etc., can solve the problems of poor taste of concentrated fish protein, limited application range, high toxicity of acetone, etc. The effect of added value and deep processing level, broad application prospects, convenient transportation and preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

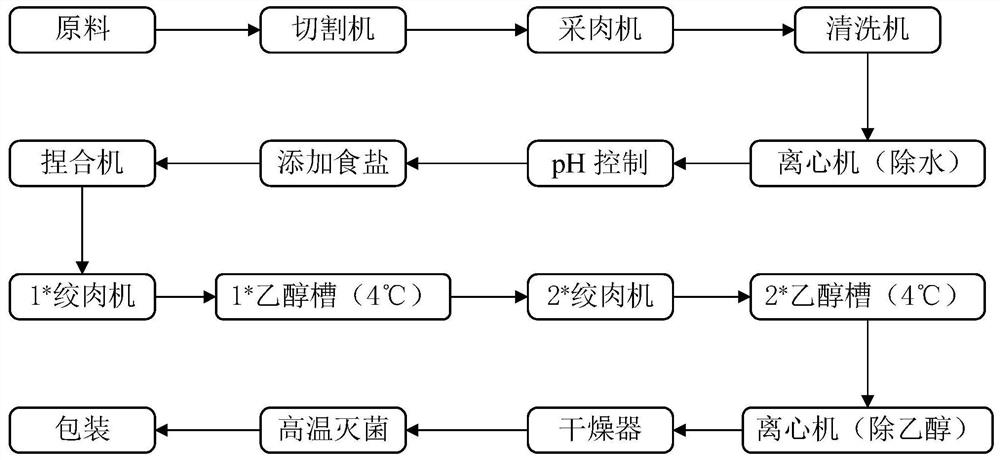

Method used

Image

Examples

Embodiment 1

[0047] (1) Thaw 500g of frozen fish, remove the fish head and viscera, and separate the bone spurs to obtain minced fish;

[0048] (2) Rinse the minced fish meat with 0.4% sodium bicarbonate solution for 5 minutes, remove the fat in the fish meat, and then centrifuge to remove the remaining water, at a centrifugal rate of 1000 rpm / min, for a centrifugation time of 5 minutes, and at a centrifugation temperature of 4° C.;

[0049] (3) Mix the minced fish with baking soda and step (2), and adjust the pH to 8.5;

[0050] (4) Add 2% salt compared to the quality of step (1) minced fish in the minced fish in step (3), and knead until it becomes paste fish;

[0051] (5) Mix the paste fish in step (4) with cold ethanol at 4°C (the ratio of the volume of cold ethanol to the mass of paste fish is 5:1), stir for 15 minutes, after the fish protein is coagulated, remove the ethanol by centrifugation, and recover Ethanol in the upper layer, the conditions are centrifugation rate 1000rpm / min...

Embodiment 2

[0058] (1) Thaw 500g of frozen fish, remove the fish head and viscera, and separate the bone spurs to obtain minced fish;

[0059] (2) Rinse the minced fish meat with 0.4% sodium bicarbonate solution for 5 minutes, remove the fat in the fish meat, and then centrifuge to remove the remaining water, at a centrifugal rate of 1000 rpm / min, for a centrifugation time of 5 minutes, and at a centrifugation temperature of 4° C.;

[0060] (3) Mix the minced fish with baking soda and step (2), and adjust the pH to 8.5;

[0061] (4) Add 2% salt compared to the quality of step (1) minced fish in the minced fish in step (3), and knead until it becomes paste fish;

[0062](5) Mix the pasty fish in step (4) with cold ethanol at 4°C that is 5 times the volume of the pasty fish in step (4), and stir for 15 minutes. After the fish protein is coagulated, remove the ethanol by centrifugation, and recover the upper layer of ethanol , the condition is that the centrifugation rate is 1000rpm / min, th...

Embodiment 3

[0071] With reference to embodiment 1, the consumption of control step (5) salt is 0.5%, 1%, 2%, 3%, 5%, all the other conditions are constant, and the concentrated fish protein property that makes is as shown in table 2.

[0072] Table 1 Comparison table of properties of concentrated fish protein prepared with different amounts of salt

[0073] Salt amount Hardness (g) Elasticity (mm) Cohesion Resilience Chewiness (J) Rehydration ratio 0.5% 2549.483 0.578 0.552 0.276 813.428 2.7 1% 2870.115 0.715 0.584 0.314 1198.445 3.5 2% 3150.487 0.793 0.627 0.332 1566.457 3.7 3% 3324.871 0.684 0.604 0.325 1373.624 3.4 5% 3569.481 0.524 0.496 0.308 927.722 2.9

[0074] The experimental results show that the amount of salt has a great influence on the texture and rehydration ratio of the product. When the salt content is 2%, the texture and taste of the product are the best, and the rehydration ratio is also the best...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com