Method for preparing platinum monatomic material by using alkyl imidazole ionic liquid

A technology of ionic liquid and alkylimidazole, which is applied in the field of single-atom catalysts, can solve problems such as the easy aggregation of platinum single atoms, the narrow electrochemical window of ion mass transfer, and the impact on the hydrogen evolution performance of single-atom platinum electrocatalysts. Low requirements, controllable process, and the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

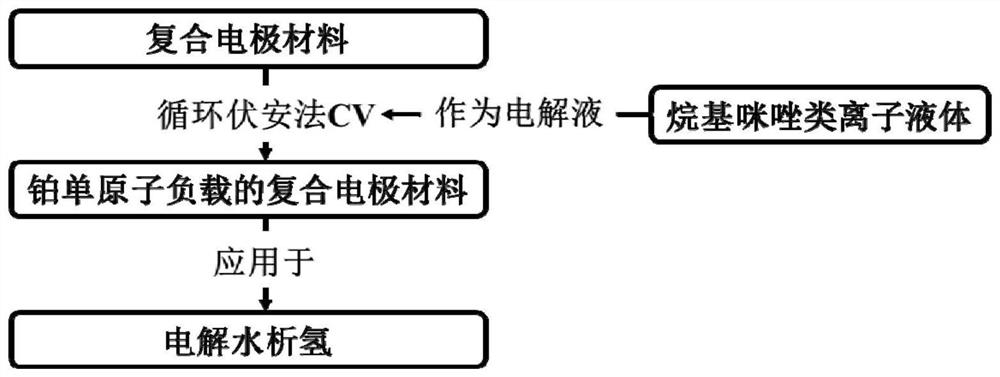

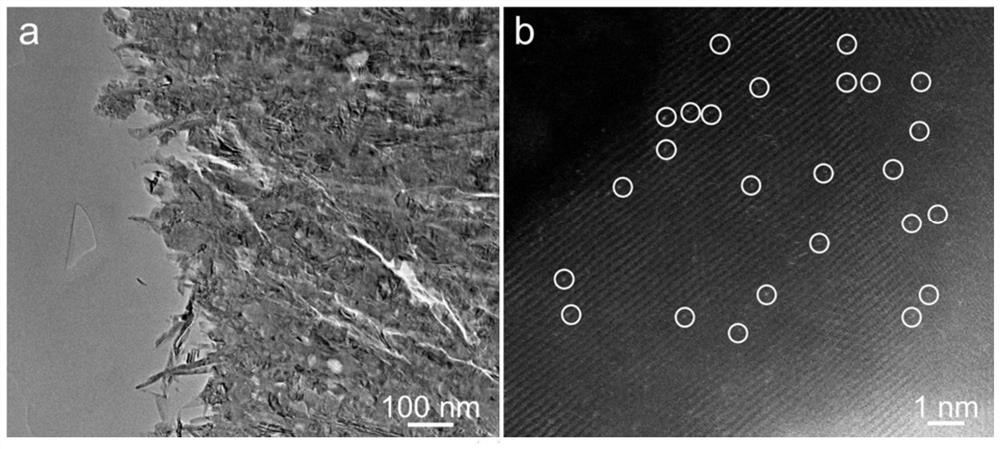

[0029] In this example, the method for preparing Pt single-atom materials from 1-ethyl-3-methylimidazolium tetrafluoroborate ionic liquid is mainly introduced. The process flow is as follows figure 1 As shown, the specific operation steps are as follows:

[0030] Step 1, 2.38g nickel chloride hexahydrate, 1.19g cobalt chloride hexahydrate, 0.3g graphene oxide (GO) solid particles are dissolved in the deep eutectic solution, and the deep eutectic solution is dissolved in ethyl alcohol by choline chloride It is formed in diol, and the formed black solution is used as the electrolyte, and the constant potential compounding is carried out in a standard three-electrode system composed of a nickel sheet as a counter electrode, a carbon cloth (CC) as a working electrode, and a non-mercury wire electrode as a reference electrode. Electrodeposition with a voltage of -0.6V to obtain a Ni-Co-GO composite electrode material; place the Ni-Co-GO composite electrode material in a tube furnac...

Embodiment 2

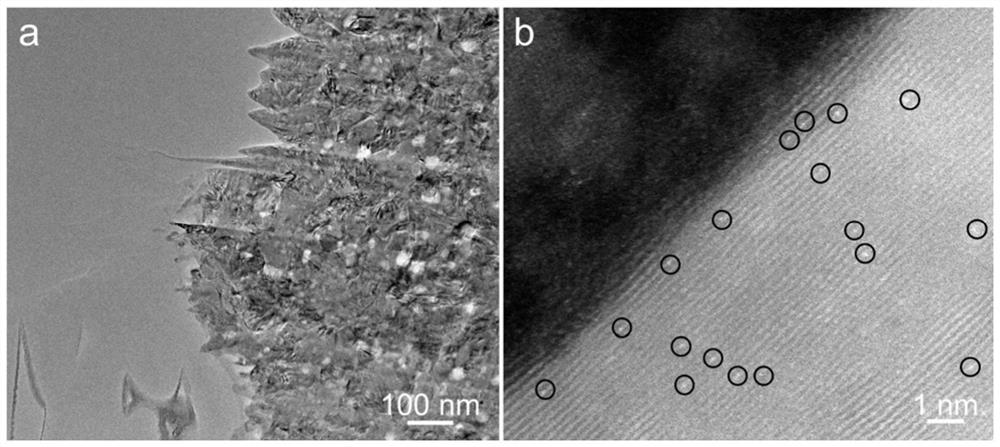

[0035] In this example, the method for preparing Pt single-atom materials from 1-butyl-3-methylimidazolium tetrafluoroborate ionic liquid is mainly introduced. The process flow is as follows figure 1 As shown, the specific operation steps are as follows:

[0036] Step 1, 4.96g nickel chloride hexahydrate, 2.38g cobalt chloride hexahydrate, 0.3g graphene oxide (GO) solid particles are dissolved in the deep eutectic solution, and the deep eutectic solution is dissolved in ethyl alcohol by choline chloride It is formed in diol, and the formed black solution is used as the electrolyte, and the constant potential compounding is carried out in a standard three-electrode system composed of a nickel sheet as a counter electrode, a carbon cloth (CC) as a working electrode, and a non-mercury wire electrode as a reference electrode. Electrodeposition with a voltage of -0.7V to obtain a Ni-Co-GO composite electrode material; place the Ni-Co-GO composite electrode material in a tube furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com