Coal-based carbon negative electrode material, preparation method and application thereof, and battery containing coal-based carbon negative electrode material

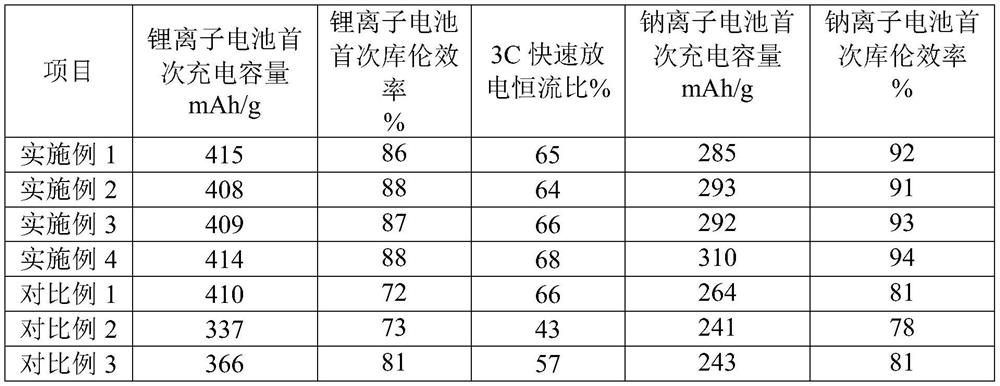

A negative electrode material, coal-based technology, applied in the field of coal-based carbon negative electrode materials and its preparation, can solve the problems of unfavorable industrial production and commercial development, unsatisfactory fast charging performance, low initial Coulombic efficiency, etc., and achieve excellent sodium ion intercalation , low price, and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] ①Pretreatment of coal-based raw materials

[0084] Firstly, the cleaned coal is crushed until the D50 is 50 μm, and then it is put into an electric heating ribbon mixer and continuously fed with air for oxidation operation. The volume of the pulverized coal-based raw material is equal to the effective volume of the electric heating ribbon mixer 50%, the temperature is raised to 200°C, and the ventilation frequency is 0.2 times / min. After continuing to heat up to 250°C, the temperature was raised to 350°C at a rate of 20°C / hour, and the oxidation time was 6 hours. After the reaction, the material was cooled to room temperature and then pulverized and sieved by air flow to obtain coal powder with a D50 of 8 μm and a volatile content of 8%.

[0085] ②Low temperature heat treatment

[0086]Add coal tar pitch with a mass percentage of 5%, a softening point of 180°C, a residual carbon value of 38%, and a D50 of 5 μm to the pretreated coal powder, mix evenly in a fusion mach...

Embodiment 2

[0090] 1. the pretreatment of coal-based raw material: with embodiment 1

[0091] 2. low temperature heat treatment: with embodiment 1

[0092] ③High temperature heat treatment

[0093] The low-temperature heat-treated material was put into an argon-protected ceramic tube furnace. Under normal pressure, the air exchange frequency was 0.3 times / min. The material was maintained at 1500°C for 3 hours to obtain a coal-based carbon negative electrode material. The argon gas is 0.05 times / minute according to the ventilation frequency.

Embodiment 3

[0095] 1. the pretreatment of coal-based raw material: with embodiment 1

[0096] ②Low temperature heat treatment

[0097] Add anthracene with a mass percentage of 15% to the pretreated coal powder, mix evenly in the fusion machine, put it into the rotary furnace, and perform low-temperature heat treatment. Air is first introduced, and the air exchange frequency is 0.2 times / min, 3°C / min Raise the temperature to 360°C and keep it for 3 hours, switch to nitrogen protection, the ventilation frequency is 0.05 times / min, and raise the temperature to 600°C at 3°C / min and keep it for 3 hours, and the specific surface area is 3m 2 / g, the modified coal powder with a volatile content of 5%.

[0098] 3. high temperature heat treatment: with embodiment 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com