Anion exchange membrane of imidazolium covalently modified fluorine-containing resin and preparation method of anion exchange membrane

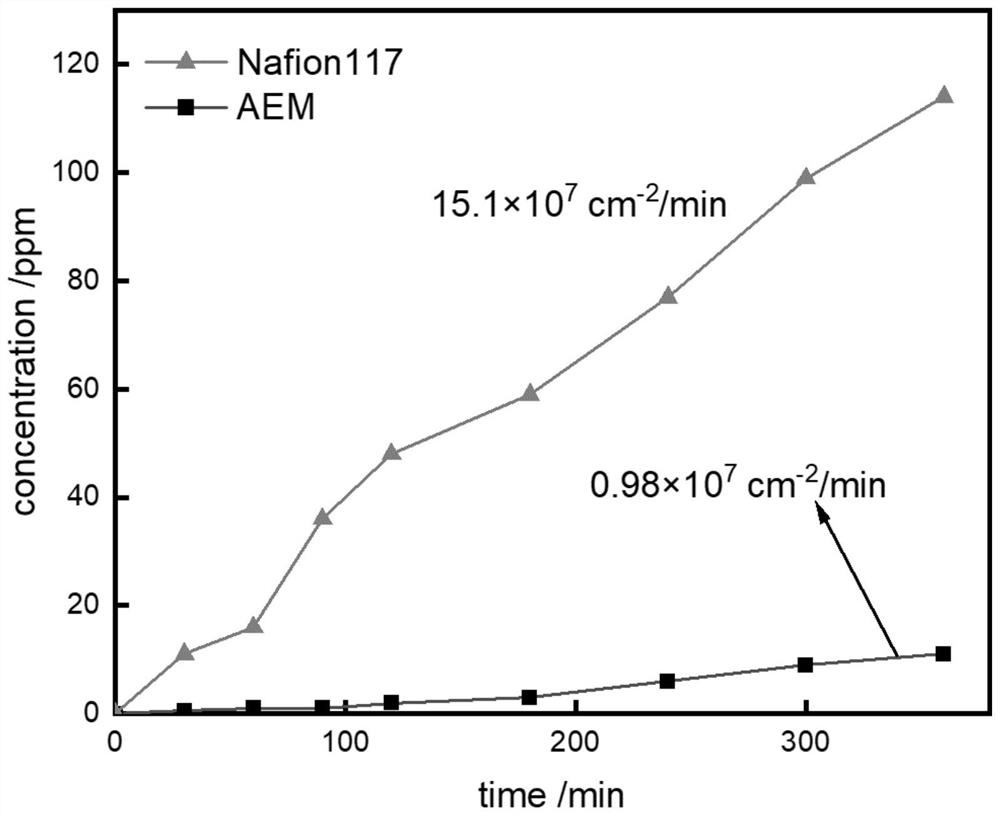

A technology of anion exchange membrane and fluorine-containing resin, applied in the field of ion exchange membrane, can solve the problem of lack of anion exchange membrane, and achieve the effects of low price, reducing the degree of monomer self-polymerization, and low vanadium permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

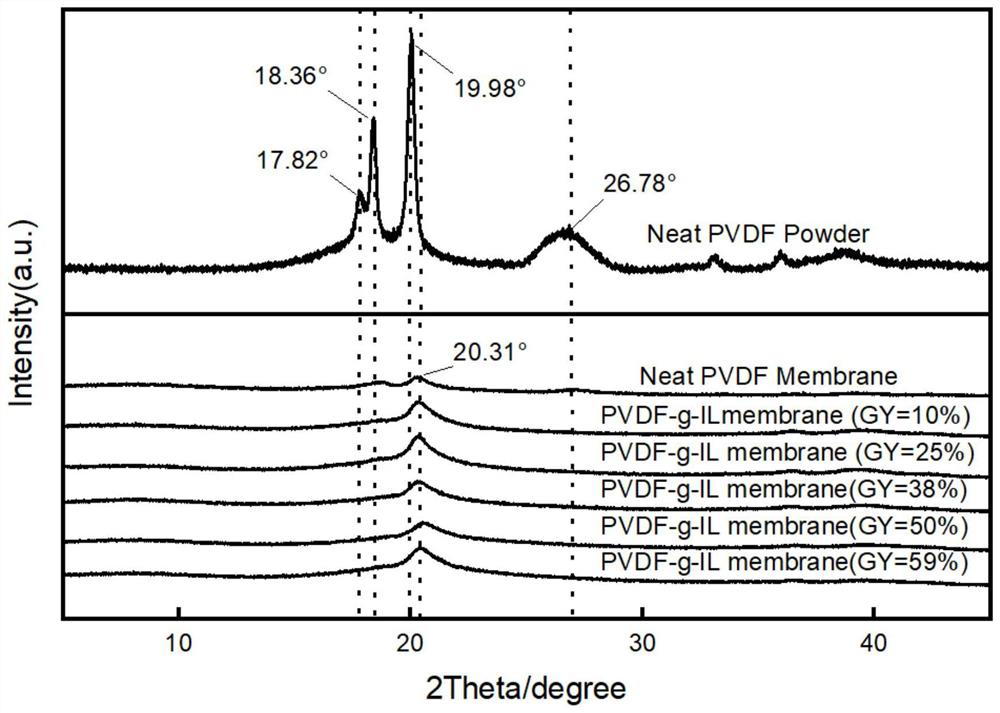

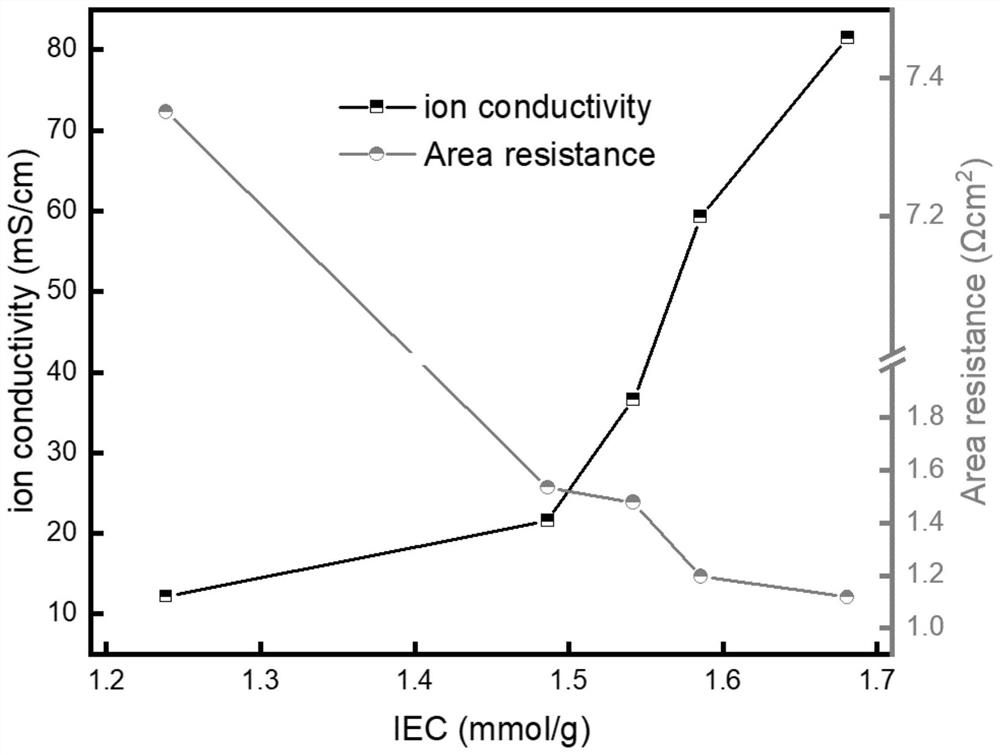

[0035] An all-vanadium redox flow battery uses imidazolium to covalently modify the polyvinylidene fluoride anion exchange membrane, which is prepared by the following method:

[0036] (1) Put 10g of polyvinylidene fluoride powder into a polyethylene bag and lay it flat, vacuumize and seal it and place it on a trolley covered with dry ice for pre-irradiation with electron beams, the absorbed dose is 140kGy, and then put the irradiated The polyvinylidene fluoride powder was stored in dry ice.

[0037] (2) Add 30g of 1-vinyl-3-ethylimidazolium tetrafluoroborate, 3g of Tween 20 and 67g of deionized water into a 250ml three-neck flask, stir for 30 minutes under a nitrogen atmosphere, then quickly pour into the irradiated The finished powder was stirred and reacted at 60°C for 6 hours, and the obtained product was filtered and washed repeatedly with deionized water and ethanol to remove unreacted modified monomers, and then dried for later use.

[0038](3) Weigh 2 g of dry powder,...

Embodiment 2

[0040] Weigh 2g of dry powder, dissolve in 18g of N-methylpyrrolidone, stir and dissolve at 60°C for 24 hours to form a casting solution with a mass fraction of 10%. After standing still for 6 hours to remove air bubbles, place it upside down on a clean horizontal glass plate. After standing still for 5-10 minutes, place it in an oven at 60°C to dry and remove N-methylpyrrolidone, and soak the diaphragm in 1M sulfuric acid solution 24 hours to obtain a PVDF diaphragm.

Embodiment 3

[0042] The same method as in Example 1, but the difference is that the absorbed dose is 40 kGy, and the grafting rate GY is only about 10%, which has limited improvement in performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com