Biomass-based multifunctional photo-thermal protective coating with photo-thermal temperature rise function and preparation method of biomass-based multifunctional photo-thermal protective coating

A protective coating and biomass technology, applied in the field of biomass-based multifunctional photothermal protective coating and its preparation, can solve the effect of stains on the photothermal performance of the deicing surface, cannot simultaneously take into account multiple protective effects, and photothermal conversion Poor efficiency and other problems, to overcome the lack of durability, reduce heat loss, and obtain simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention discloses a rapid photothermal heating biomass-based multifunctional photothermal protective coating and a preparation method thereof. The preparation method specifically includes the following steps:

[0039] Step 1, putting cellulose into a tube furnace for calcination to obtain carbonized hollow microtubes (CHMT), the main component of which is carbon;

[0040] Specifically, the cellulose is put into a tube furnace for calcination, the temperature of the tube furnace is 400-1000° C., the heating rate is 1-15° C. / min, and the calcination time is 15-200 minutes to obtain carbonized hollow microtubes ( CHMT).

[0041] Wherein, the cellulose is biomass-based cellulose, which includes but not limited to one or more mixtures of bamboo fiber, cotton fiber, kapok fiber, wood fiber and absorbent cotton, and the hollow space formed by different cellulose Microtubules vary in size.

[0042] Step 2, adding CHMT to an organic solvent, and ultrasonically forming a ...

Embodiment 1

[0047]

[0048]

[0049] The kapok cellulose was put into a tube furnace for calcination. The temperature of the tube furnace was 400° C., the heating rate of the tube furnace was 3° C. / min, and the calcination time was 30 minutes to obtain hollow carbon microtubes (CHMT). CHMT was added to a mixture of ethanol (20 mL) and ethyl acetate (20 mL), and a uniform slurry A was formed by ultrasonication, wherein the concentration of CHMT was 4 mg / mL, the ultrasonic power was 60 W, and the ultrasonic time was 10 min.

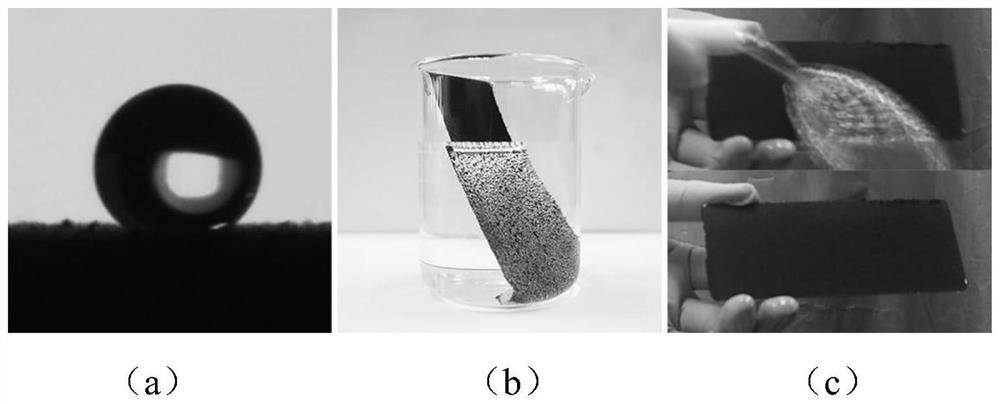

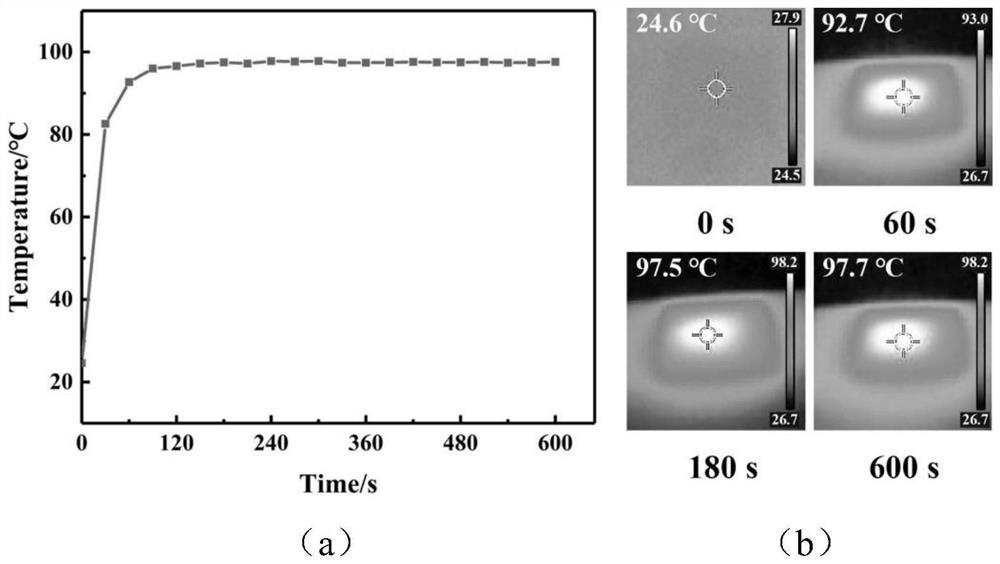

[0050] Add 0.95g of silicone resin and 0.5g of curing agent to the above mixed solution, stir at a speed of 1000r / min for 5min to obtain slurry B, then dip-coat the dispersed mixed solution on the wood substrate, at 110°C After curing for 2 hours, a hydrophobic photothermal deicing coating was obtained. Such as figure 1 As shown, the water droplet has a large contact angle and presents a spherical shape on the coating surface. At the same time, it can be seen th...

Embodiment 2

[0052]

[0053]

[0054] Bamboo fibers were put into a tube furnace for calcination. The temperature of the tube furnace was 600° C., the heating rate of the tube furnace was 5° C. / min, and the calcination time was 60 min to obtain hollow carbon microtubes (CHMT). CHMT was added to a mixture of ethanol (10 mL) and acetone (30 mL), and a uniform slurry A was formed by ultrasonication, wherein the concentration of CHMT was 8 mg / mL, the ultrasonic power was 60 W, and the ultrasonic time was 15 min.

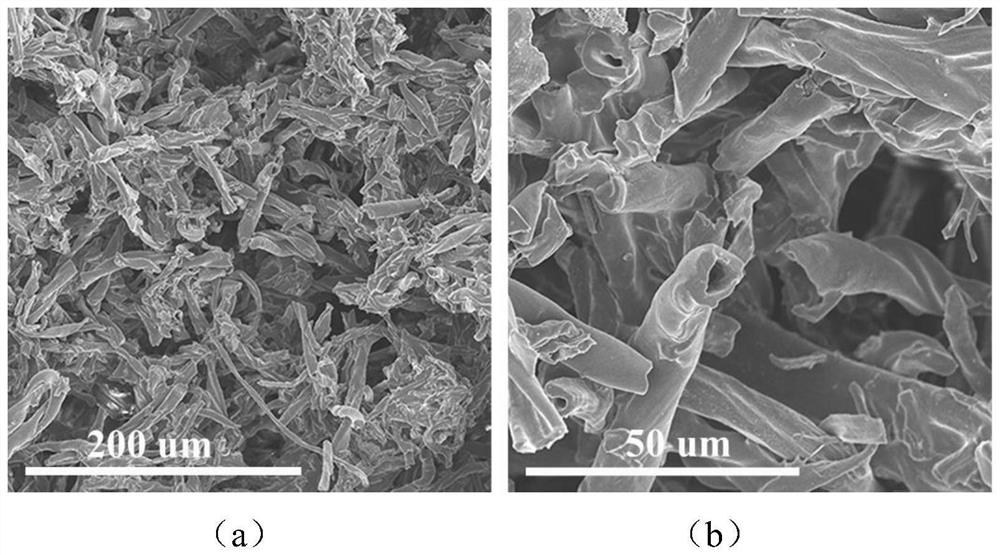

[0055] Add 1g of epoxy resin and 0.1g of curing agent to the above mixed solution, stir at a speed of 500r / min for 10min to obtain slurry B, and then spray the dispersed mixed solution on the glass substrate at a spraying angle of 70° , the distance between the spray gun and the surface of the substrate was 20 cm, and cured at 100 °C for 10 h to obtain a hydrophobic photothermal deicing coating. Such as figure 2 As shown, the scanning electron microscope analysis of the prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com