X-ray direct detector and preparation method thereof

A detector and X-ray technology, applied in the field of X-ray direct detector and its preparation, can solve the problems of low X-ray absorption efficiency, low detection sensitivity, poor electrical signal collection and imaging effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

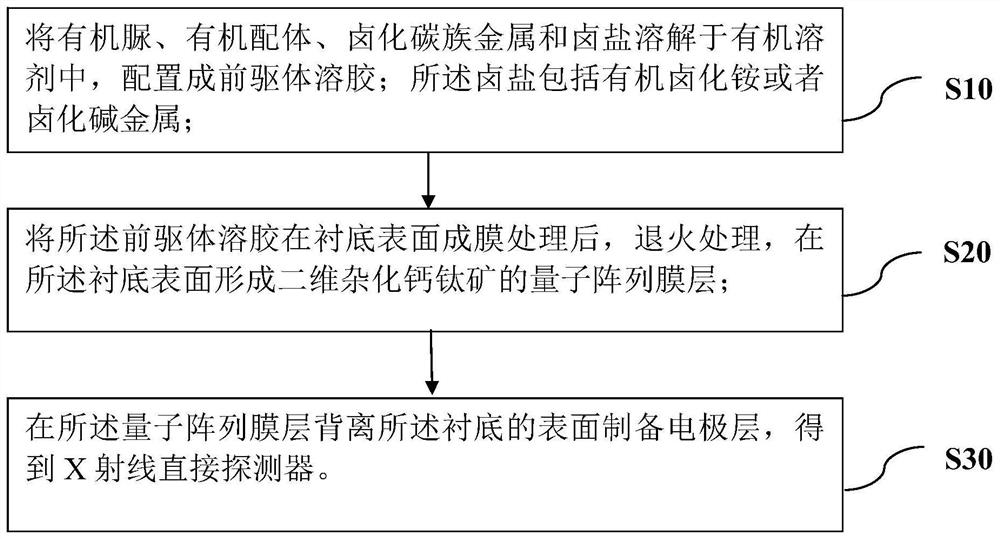

[0047] as attached figure 1 , the first aspect of the embodiment of the present application provides a method for preparing an X-ray direct detector, comprising the following steps:

[0048] S10. Dissolving organic urea, organic ligand, carbon group metal halide and halide salt in an organic solvent to form a precursor sol; the halide salt includes organic ammonium halide or alkali metal halide;

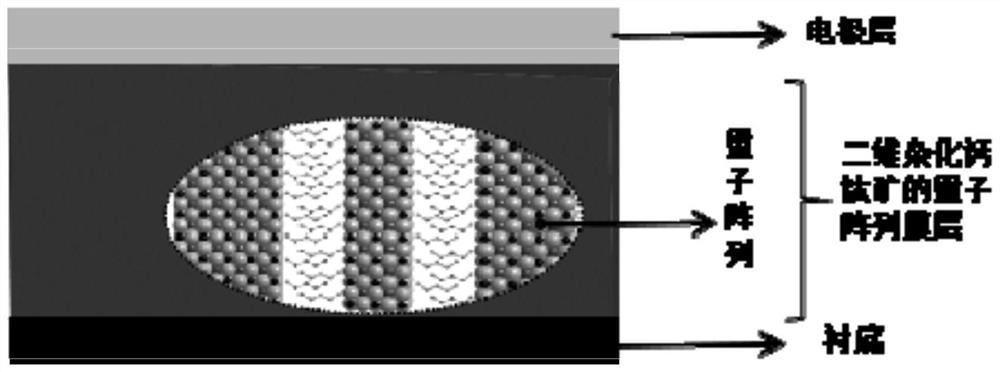

[0049] S20. After the precursor sol is formed into a film on the surface of the substrate, annealing is performed to form a two-dimensional hybrid perovskite quantum array film on the surface of the substrate;

[0050] S30. Prepare an electrode layer on the surface of the quantum array film layer away from the substrate to obtain a direct X-ray detector.

[0051] In the preparation method of the X-ray direct detector provided in the first aspect of the embodiment of the present application, organic urea is added when configuring the precursor sol, and the organic urea contains -NH ...

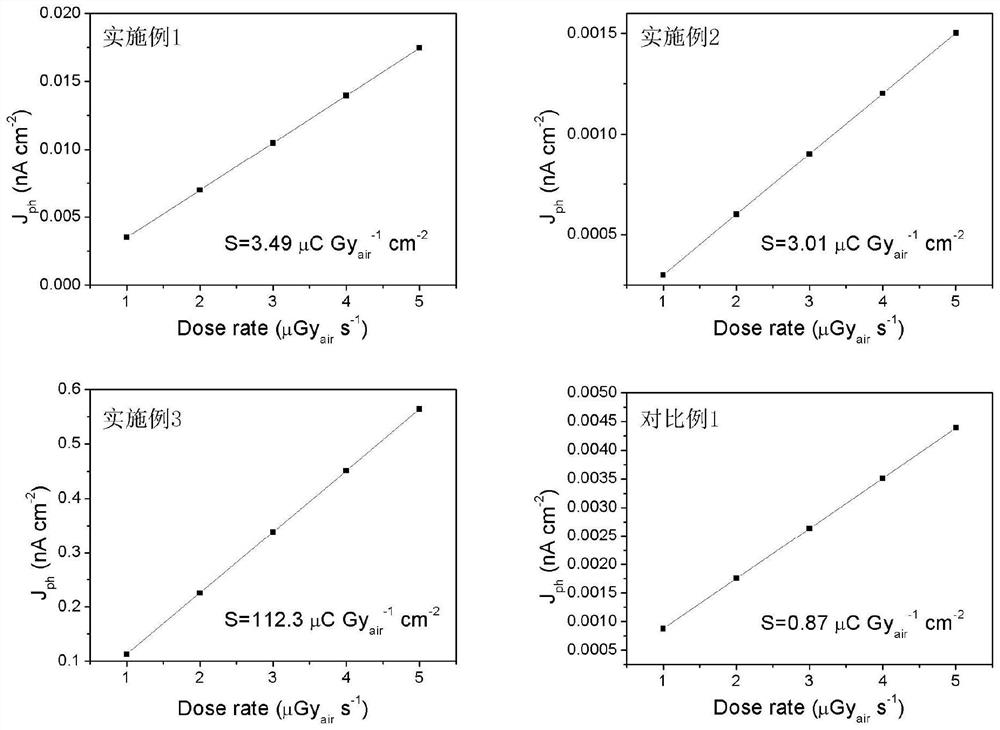

Embodiment 1

[0082] A kind of X-ray direct detector, its preparation comprises the steps:

[0083] ① Dissolve semicarbazide, ammonium chloride, n-butylamine hydroiodide, methylamine hydroiodide, and lead iodide in dimethyl sulfoxide and N,N-dimethylformaldehyde at a volume ratio of 2:3 In the mixed solvent mixed solvent of amide, wherein, the mol ratio of n-butylamine hydroiodide, methylamine hydroiodide, lead iodide is 2:3:4, and the initial concentration of lead iodide in solvent is 3mol / L, the total volume of solvent is 0.5ml, the addition of semicarbazide is 10% of lead iodide, and the addition of ammonium chloride is 10% of lead iodide. Put the obtained mixed solution in a glass bottle with a cover to prevent volatilization of solvents and additives, and stir in a nitrogen-filled glove box at 65°C for 2 hours, then open the container, heat the solution to 100°C, and set the constant temperature time for 30s , Concentrate the solution, then stop heating, cover the bottle cap, make th...

Embodiment 2

[0088] An X-ray direct detector, which differs from Embodiment 1 in that no ammonium chloride is added in step ①.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com