Preparation method and application of chemical black nickel plating solution

A technology of chemical plating and black nickel, which is applied in the direction of liquid chemical plating, metal material coating technology, coating, etc., can solve the problems of limited application range, insufficient corrosion resistance of the plating layer, insufficient discoloration resistance, and high production cost, and achieve The reduction deposition rate is easy to control, the physical and chemical properties are easy to control, and the effect of rich complexes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A kind of preparation method of chemical black nickel plating solution of the present invention, comprises the steps:

[0041] §1. Prefabricated liquid: under the condition of 35-55°C, dissolve every 3-8g of surfactant and 5-30g of nickel complex in sequence in 1L of aqueous solution of additive A with a concentration of 10-35g / L;

[0042] §2. Adding auxiliary metal ions: Add 25-125g of nickel sulfate, 5-30g of nickel acetate, 2-12g of manganese salt, and 1-6g of zinc to the solution obtained in step §1 at 35-55°C. compound, 0.5-3g silver nitrate, stir until all salts are completely dissolved;

[0043] §3. Prepare the main solution: Add 3-25g of additive B and 2-8g of additive C to the solution obtained in step §2 at 35-55°C, respectively, and stir until additive B and additive C are completely dissolved. Obtain chemical black nickel main solution (hereinafter referred to as "main solution");

[0044] §4. Preparation of reducing solution: under the condition of 35-55°...

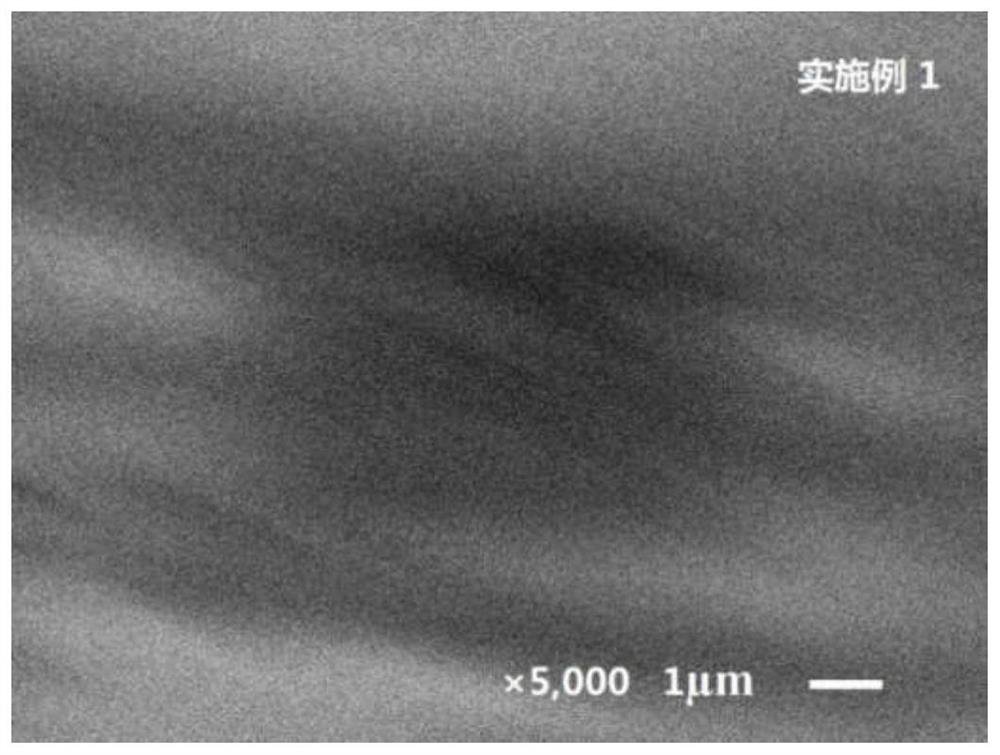

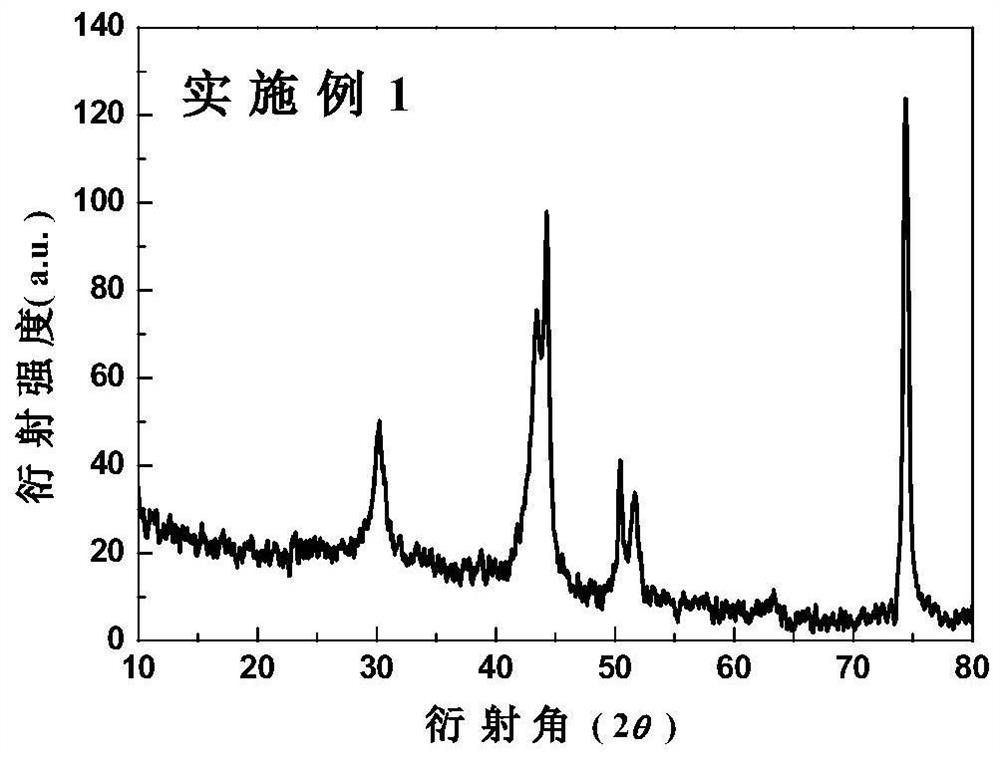

Embodiment 1

[0070] A preparation method of chemical black nickel plating solution, prepared according to the following steps:

[0071] §1. Dissolve 3g of SDS and 5g of CS-Ni in sequence in 1L of sodium oxalate solution with a concentration of 10g / L at 35°C;

[0072] §2. Keeping at 35°C, add 25g of nickel sulfate, 5g of nickel acetate, 2g of manganese sulfate, 1g of zinc sulfate, and 0.5g of silver nitrate to the solution obtained in step §1, and stir until the various salts are completely dissolved;

[0073] §3. At 35°C, add 5g of water-soluble CS, 1g of oxalic acid, and 1g of malonic acid to the solution obtained in step §2, respectively, and stir until completely dissolved to obtain the main solution of chemical black nickel plating solution (main liquid);

[0074] §4. Dissolve 35g of sodium hypophosphite, 5g of glucose, 1g of hydroxylamine sulfate, and 2g of thioacetamide in 1L of water at 35°C to make a mixed reducing agent solution (reducing solution);

[0075] §5. Add the reducing...

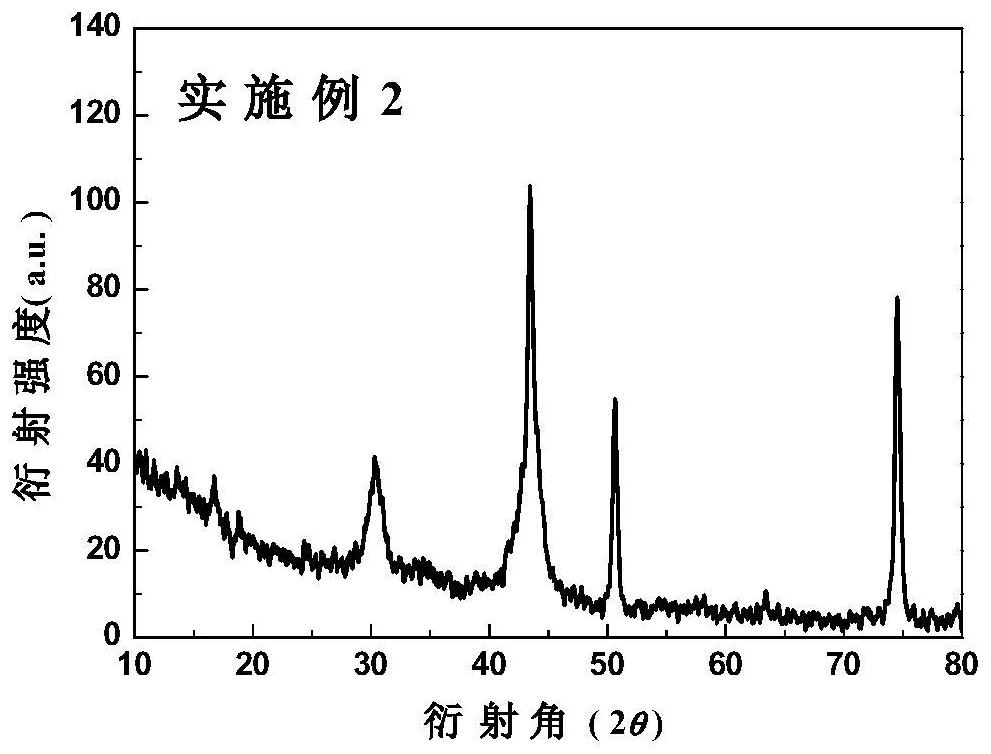

Embodiment 2

[0078] A preparation method of chemical black nickel plating solution, prepared according to the following steps:

[0079] §1. Dissolve 2gSDS, 2gCTAB, 5gCS-Ni, 5gCSO-Ni in 1L sodium oxalate solution with a concentration of 15g / L at 45℃;

[0080] §2. Keeping at 45°C, add 45g of nickel sulfate, 10g of nickel acetate, 4g of an equal mass mixture of manganese sulfate and manganese nitrate, 2g of zinc nitrate, and 1g of silver nitrate to the solution obtained in step §1, and stir until various salts completely dissolved;

[0081] §3. At 45°C, add 5g of water-soluble chitosan and 3g of malonic acid to the solution obtained in step §2, and stir until the additives are completely dissolved to obtain the main solution;

[0082] §4. Dissolve the reducing agent: 55g of sodium hypophosphite, 10g of glucose, 3g of hydroxylamine sulfate, 4g of thioacetamide and thiopropionamide in 1L of water to prepare the reducing agent. stock solution;

[0083] §5. Add the reducing solution obtained i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com