Bright black nickel electroplating solution, preparation method thereof, electroplated part and electroplating method of bright black nickel

A technology for electroplating solution and electroplating parts, which is applied to bright black nickel electroplating solution and its preparation, electroplating of electroplating parts and bright black nickel, can solve the problems of contamination and perspiration, affecting the brightness and decorative performance or electrical conductivity of the coating layer, etc. Achieve the effect of high plating temperature, improved density and bright characteristics, and low concentration of free metal ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

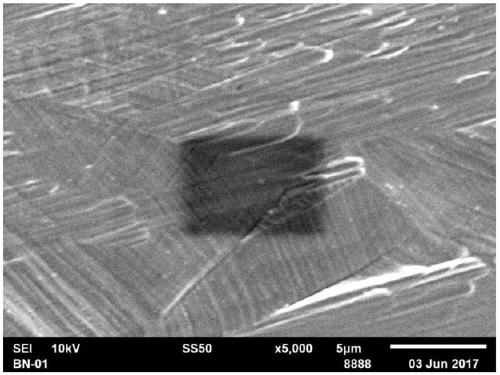

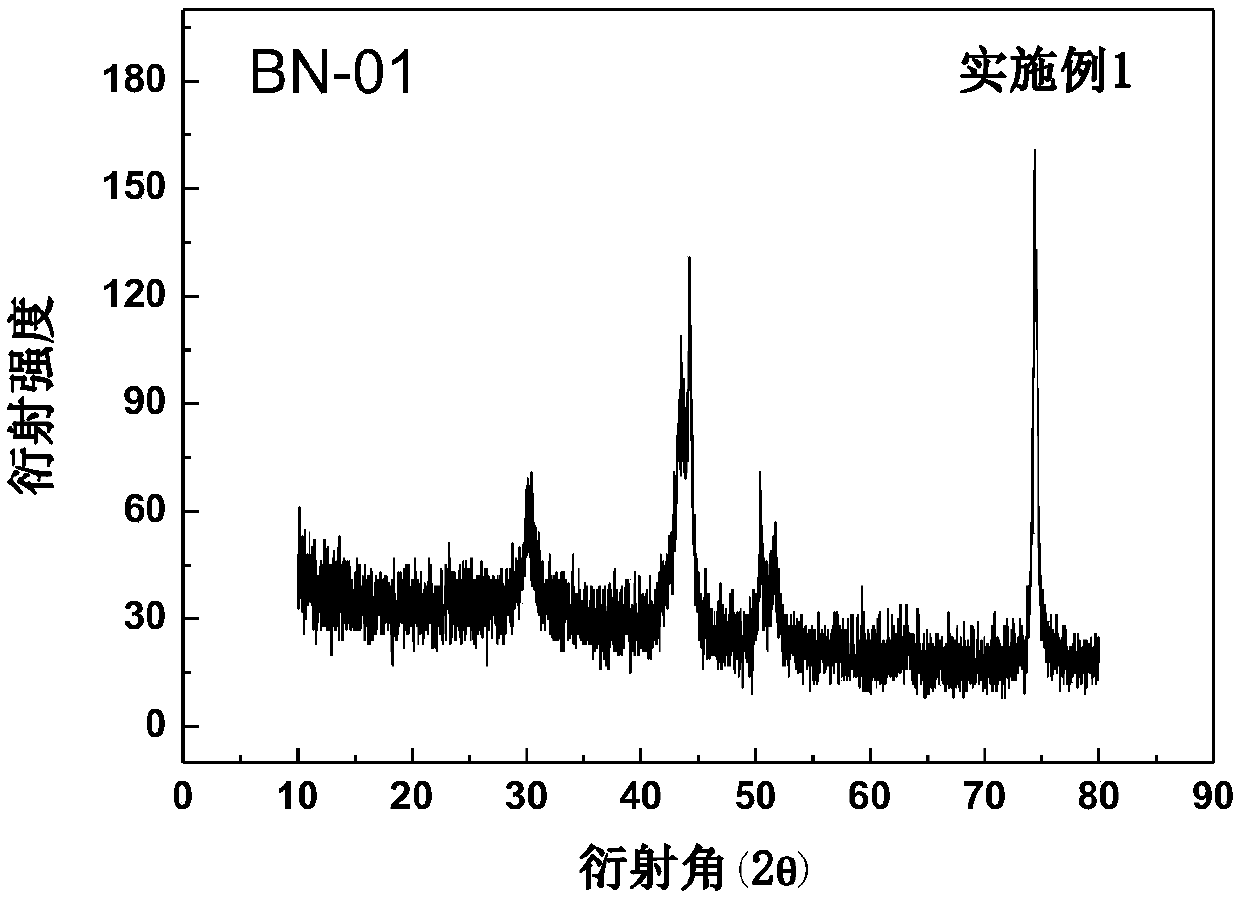

Embodiment 1

[0063] A preparation method of bright black nickel electroplating solution, the steps are:

[0064] In the first step, dissolve 5g of chitosan with nickel in 1L of a solution of 10mL / L sodium acetate (additive A, the same below, omitted) and heat at 35°C; in the second step, add 105g of nickel sulfate and nickel chloride in sequence 15g, magnesium sulfate 3g, copper sulfate 2g, ammonium thiocyanate 55g, stir until nickel salt, magnesium salt, copper salt and ammonium salt are completely dissolved; the third step, add water-soluble chitosan (additive B, the same below, omitted) 55g, stir until chitosan is completely dissolved; the 4th step, add the hexamethylenediamine of 65g equimolar ratio, butylenediamine mixture (additive C, hereinafter the same, abbreviated), 1g sodium sulfide (additive D, hereinafter the same, Slightly), continue to stir until the two dissolve completely, the solution becomes transparent or translucent, and cool to room temperature to obtain a bright blac...

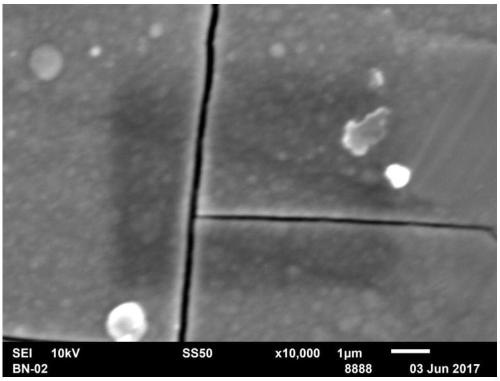

Embodiment 2

[0067] A preparation method of bright black nickel electroplating solution, the steps are:

[0068] In the first step, dissolve 15g of chitosan and nickel in 1L of sodium acetate solution with a concentration of 25mL / L, and heat at 45°C; in the second step, add 85g of nickel sulfate, 25g of nickel chloride, 2g of magnesium sulfate, and 2g of copper sulfate in sequence , ammonium thiocyanate 35g, stir until the nickel salt, magnesium salt, copper salt and ammonium salt are completely dissolved; the third step, add 45g of water-soluble chitosan, stir until the chitosan is completely dissolved; the fourth step, add etc. 55g of pentamethylenediamine, butylenediamine, and 2g of ammonium sulfide molarly mixed, continue to stir until the two are completely dissolved, and the solution becomes transparent or translucent, and cooled to room temperature to obtain a bright black nickel electroplating solution.

[0069] According to the conventional continuous electroplating process, the c...

Embodiment 3

[0071] A preparation method of bright black nickel electroplating solution, the steps are:

[0072] In the first step, dissolve 25g of chitosan with nickel in 1L of disodium hydrogen phosphate solution with a concentration of 35mL / L, and heat at 55°C; in the second step, add 65g of nickel sulfate, 15g of nickel chloride, 1g of magnesium sulfate, sulfuric acid Copper 10g, ammonium thiocyanate 25g, stir until the nickel salt, magnesium salt, copper salt and ammonium salt are completely dissolved; the third step, add 25g of water-soluble chitosan, stir until the chitosan is completely dissolved; the fourth step, respectively Add 40g of ethylenediamine, butylenediamine mixture, and 3g of ammonium sulfide mixed in equal moles, and continue to stir until the two are completely dissolved, and the solution becomes transparent or translucent. After cooling to room temperature, a bright black nickel electroplating solution is obtained.

[0073] According to the conventional continuous e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com