Hydrogen peroxide sensor electrode, preparation method and hydrogen peroxide sensor

A sensor electrode and hydrogen peroxide technology, applied in the field of electrochemical detection, can solve the problems of application of easily inactivated enzyme modified electrodes, harsh reaction conditions and high cost, and achieve the effects of promoting electron transfer, low cost and low detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

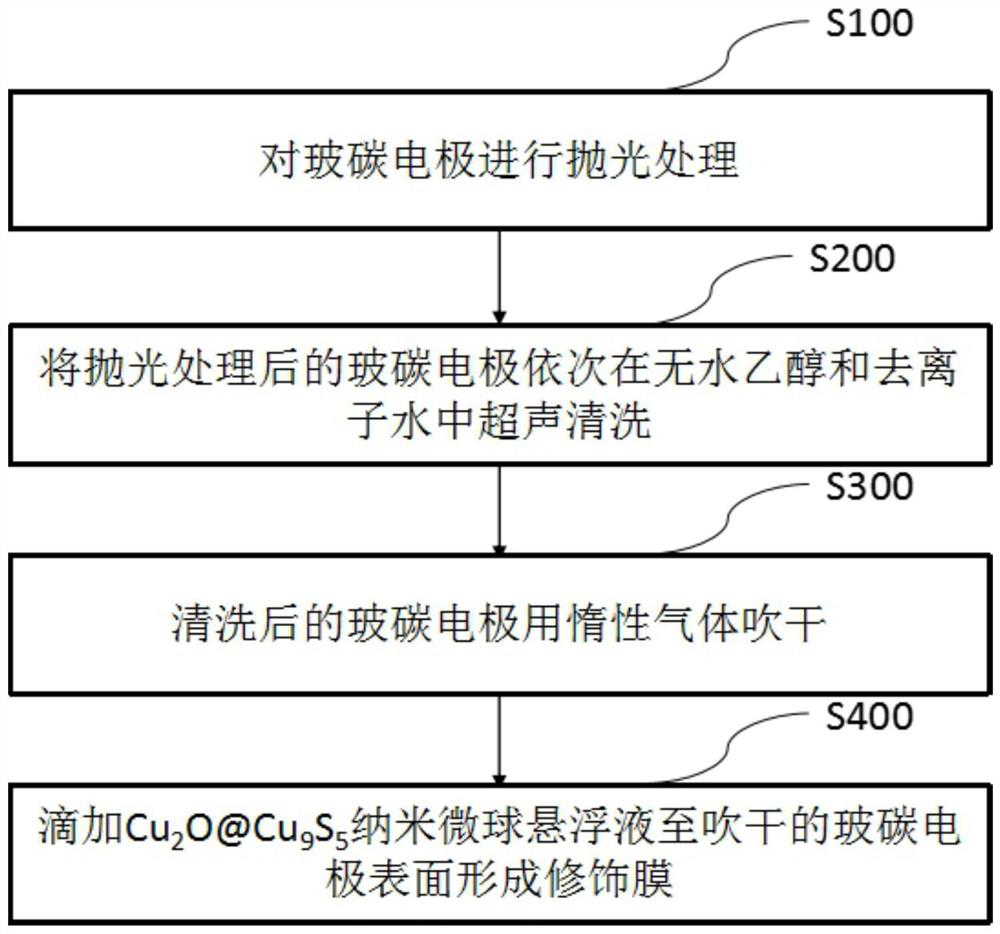

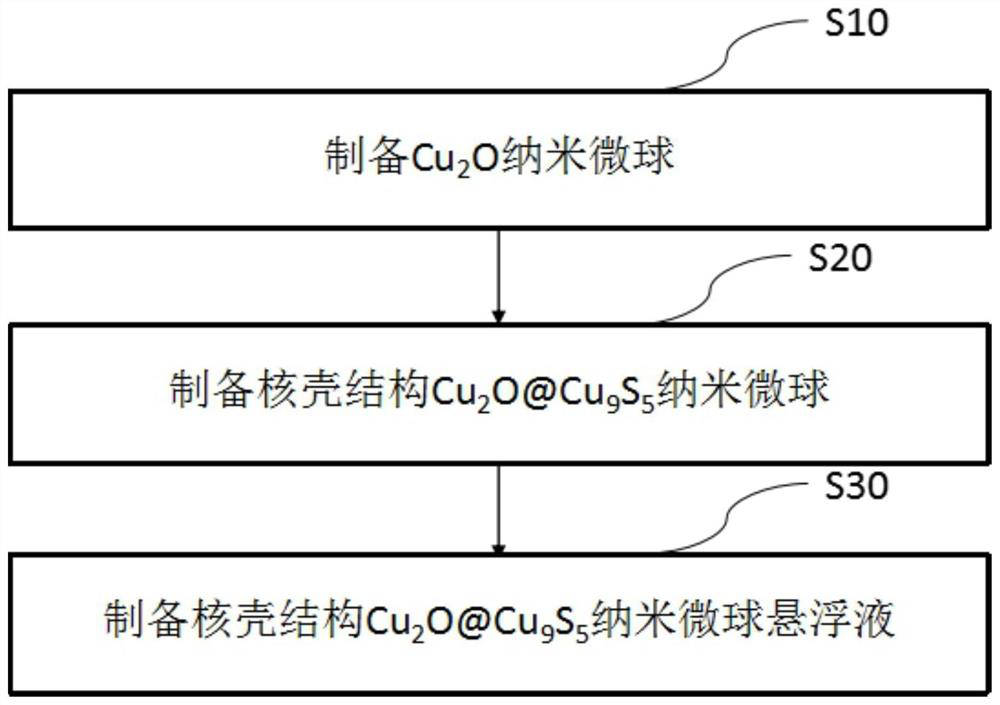

[0031] The present embodiment provides a kind of preparation method of hydrogen peroxide sensor electrode, such as figure 1 shown, including the following steps:

[0032] S100, polishing the glassy carbon electrode;

[0033] S200, ultrasonically cleaning the polished glassy carbon electrode in absolute ethanol and deionized water in sequence;

[0034] S300, drying the glassy carbon electrode after cleaning with an inert gas;

[0035] S400, adding Cu dropwise 2 O@Cu 9 S 5 The nano-microsphere suspension is applied to the surface of the dried glassy carbon electrode to form a modified film.

[0036] In this example, alumina powder or other common polishing agents are used to polish the glassy carbon electrode, and then the polished glassy carbon electrode is ultrasonicated in absolute ethanol and deionized water for 10 minutes in order to remove the residue on the glassy carbon electrode. Surface impurities, dry them with inert gas, take 10-100μL Cu 2 O@Cu 9 S 5 The sus...

Embodiment 2

[0048] This embodiment provides a hydrogen peroxide sensor electrode obtained by the preparation method in Embodiment 1.

[0049] This embodiment also provides the use of Cu 2 O nanospheres and hollow structure Cu 9 S 5 The hydrogen peroxide sensor electrode obtained by modifying the surface of glassy carbon electrode with nano-microspheres for comparison, when Cu 2 O nanospheres and Na 2 When the molar ratio of S is 1:12.4, the hollow structure Cu 9 S 5 Nano microspheres, the rest of the steps are the same as the corresponding steps in the preparation method in Example 1.

[0050] Hollow structure Cu 9 S 5 Preparation of nanospheres: Take 8mg Cu 2 O nanospheres were dissolved in 4 mL deionized water, and then 26.8 mg Na 2 S, vigorously stirred for 10 minutes; after the reaction, the above solution was centrifuged at 6000 rpm for 6 minutes, washed with ethanol and deionized water for 3 times, and finally the product was dried in a vacuum oven at 60°C for 8 hours to pr...

Embodiment 3

[0052] This embodiment provides a hydrogen peroxide sensor, the working electrode of the sensor is selected from the hydrogen peroxide sensor electrode in embodiment 2, and the working electrode of the hydrogen peroxide sensor is a core-shell structure Cu 2 O@Cu 9 S 5 A glassy carbon electrode modified by nanometer microspheres, the reference electrode is a mercury / mercury oxide electrode, and the counter electrode is a platinum sheet. After the working electrode, reference electrode and platinum sheet are assembled, they are connected to an electrochemical workstation to form a hydrogen peroxide sensor. Called sensor 1.

[0053] The present embodiment also provides two kinds of hydrogen peroxide sensors for comparison, and the working electrode adopts Cu in embodiment 2 respectively. 2 O nanospheres and hollow structure Cu 9 S 5 A glassy carbon electrode modified by nanometer microspheres, the reference electrode is a mercury / mercury oxide electrode, and the counter elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com