Hydrophilic and hydrophobic patterned array chip, preparation method and application thereof

An array chip and patterning technology, applied in the field of mass spectrometry detection, can solve the problems of increased cost and increased application difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

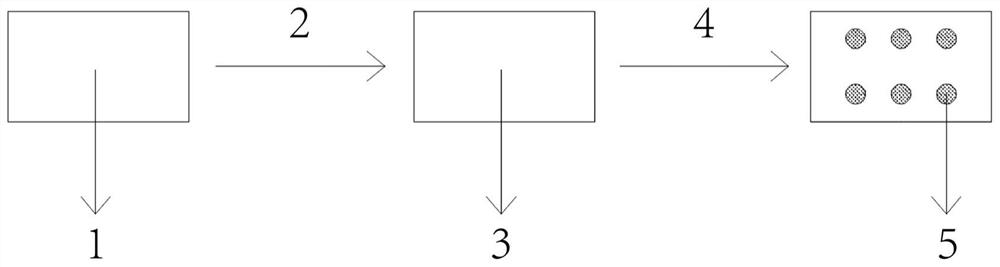

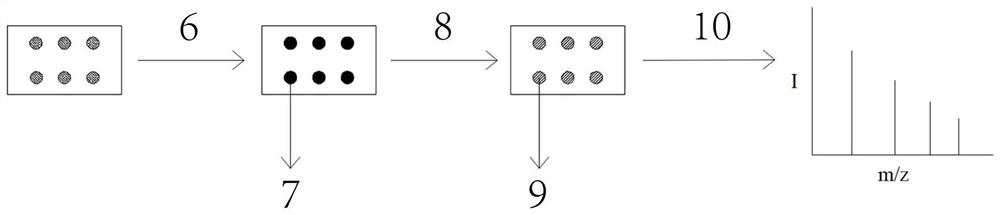

Method used

Image

Examples

Embodiment 1

[0039] Put the monocrystalline silicon [n type, (100)] into acetone, chloroform, ethanol, and ultrapure water for ultrasonic cleaning respectively, and blow dry with high-purity nitrogen. Then use O 2 -Plasma is treated with 100W power for 2 minutes to hydroxylate the surface of the silicon wafer.

[0040] Paste the hydroxylated silicon wafer on a clean upper surface dish, pipette 10 μL of heptadecafluorodecyltrimethoxysilane dropwise onto the lower surface dish, then fasten the upper surface dish, and heat and grow at 150°C for 2 hours , so that the surface of the entire silicon wafer is modified with fluorine-containing silane, making the surface of the silicon wafer hydrophobic.

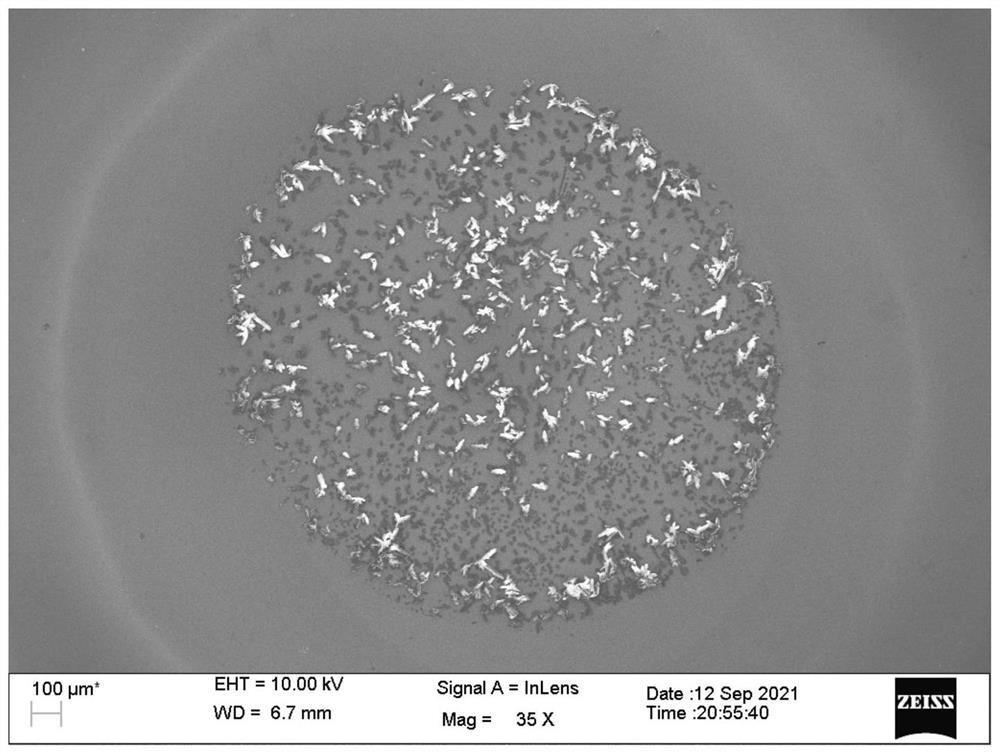

[0041] The evaporation mask with arrayed pattern (the pattern can be: circle, triangle, square or polygon, etc., the size of the pattern in the mask is 100-2000 μm, and the distance between the patterns is 500-5000 μm) is covered on the modified surface containing Fluorine monolayer silicon wafe...

Embodiment 2

[0044] The glass slides were ultrasonically cleaned in acetone, chloroform, ethanol, and ultrapure water, and dried with high-purity nitrogen. Then use O 2 -Plasma is treated with 100W power for 2 minutes to hydroxylate the surface of the glass sheet.

[0045] Attach the hydroxylated glass slide to a clean upper surface dish, pipette 10 μL of heptadecylfluorodecyltrimethoxysilane to the lower surface dish dropwise, then fasten the upper surface dish, and heat and grow at 120°C for 3 hours , so that the surface of the entire glass sheet is modified with fluorine-containing silane, making the surface of the glass sheet hydrophobic.

[0046] The evaporation mask with arrayed pattern (the pattern can be: circle, triangle, square or polygon, etc., the size of the pattern in the mask is 100-2000 μm, and the distance between the patterns is 500-5000 μm) is covered on the modified surface containing Fluorine monolayer glass slide, and put the substrate covered with the baffle upside...

Embodiment 3

[0049] Put the quartz slices into acetone, chloroform, ethanol, and ultrapure water, respectively, to ultrasonically clean them, and dry them with high-purity nitrogen. Then use O 2 -Plasma is treated with 100W power for 2 minutes to hydroxylate the surface of the quartz plate.

[0050] Paste the hydroxylated quartz plate on a clean upper surface dish, pipette 20 μL of tridecafluorooctyltrimethoxysilane dropwise on the lower surface dish, then fasten the upper surface dish, and heat and grow at 100°C for 5 hours , so that the entire surface is modified with fluorine-containing silane, making the surface hydrophobic.

[0051] The evaporation mask with arrayed pattern (the pattern can be: circle, triangle, square or polygon, etc., the size of the pattern in the mask is 100-2000 μm, and the distance between the patterns is 500-5000 μm) is covered on the modified surface containing Fluorine monolayer quartz wafer, and put the substrate covered with the baffle upside down into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com