Pentane type multi-component high-flame-retardant polyurethane composite phenolic aldehyde continuous plate composite material and preparation method thereof

A phenolic continuous plate, multi-component technology, applied in the field of polyurethane composite modification, can solve the problems of unsatisfactory physical properties, difficulty in practical promotion, high cost, easy large-scale industrial production, simple and convenient preparation method, and solve the problem of brittleness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

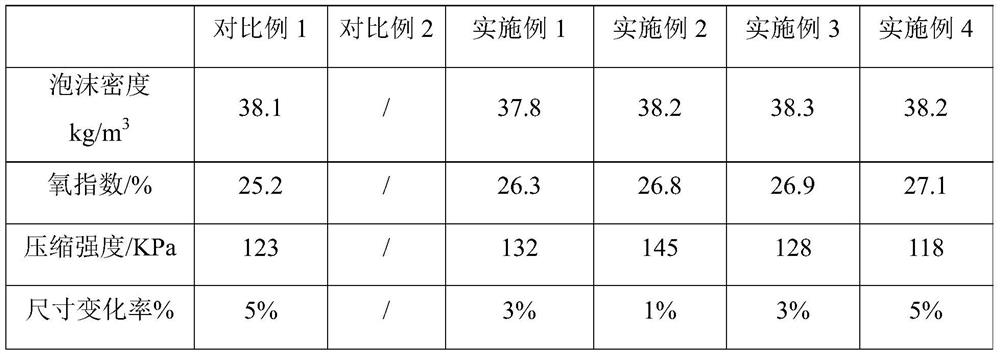

Examples

Embodiment 1

[0042] Step 1. Preparation of component A: 40 parts of 4110 polyether polyol, 30 parts of phthalic anhydride polyester, 30 parts of phenolic resin, 2 parts of hard foam silicone oil foam stabilizer, 1.0 parts of water, 30 parts of flame retardant, 2 parts The tertiary amine amine catalyst is stirred evenly according to the proportion, and the A component is obtained.

[0043] Step 2. Preparation of component B: Mix 3 parts of potassium acetate catalyst, 3 parts of formic acid curing agent, 3 parts of ethylene glycol, etc. according to the proportion and stir evenly to obtain component B.

[0044] Step 3: Take 15 parts of cyclopentane as component C; take 251 parts of isocyanate (PM200 from Wanhua) as component D.

[0045] Step 4: Mix A component, B component, C component, and D component according to the mass ratio of 135:3:15:251, pour it into a square mold of 30cm*30cm*10cm for reaction, and obtain sample block 3 .

Embodiment 2

[0047] Step 1. Preparation of component A: 40 parts of 4110 polyether polyol, 20 parts of phthalic anhydride polyester, 40 parts of phenolic resin, 2 parts of hard foam silicone oil foam stabilizer, 1.0 parts of water, 30 parts of flame retardant, 2 parts The tertiary amine amine catalyst is stirred evenly according to the proportion, and the A component is obtained.

[0048] Step 2. Preparation of component B: Mix 3 parts of potassium acetate catalyst, 4 parts of formic acid curing agent, 3 parts of ethylene glycol, etc. according to the proportion and stir evenly to obtain component B.

[0049] Step 3: Take 15 parts of cyclopentane as component C; take 251 parts of isocyanate (PM200 from Wanhua) as component D.

[0050] Step 4: Mix A component, B component, C component, and D component according to the mass ratio of 135:3:15:251, pour it into a square mold of 30cm*30cm*10cm for reaction, and obtain sample 4 .

Embodiment 3

[0052] Step 1. Preparation of component A: 40 parts of 4110 polyether polyol, 10 parts of phthalic anhydride polyester, 50 parts of phenolic resin, 2 parts of hard foam silicone oil foam stabilizer, 1.0 parts of water, 30 parts of flame retardant, 2 parts The tertiary amine amine catalyst is stirred evenly according to the proportion, and the A component is obtained.

[0053] Step 2. Preparation of component B: Mix 3 parts of potassium acetate catalyst, 5 parts of formic acid curing agent, 3 parts of ethylene glycol, etc. according to the proportion and stir evenly to obtain component B.

[0054] Step 3: Take 15 parts of cyclopentane as component C; take 251 parts of isocyanate (PM200 from Wanhua) as component D.

[0055] Step 4. Mix components A, B, C and D according to the mass ratio of 135:3:15:251, and pour them into a square mold of 30cm*30cm*10cm for reaction to obtain a sample block 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com