Sludge drying and recycling system

A sludge and sludge pump technology, applied in the field of sludge drying and reuse system, can solve problems such as blockage of coal conveying system, achieve the effects of avoiding waste, improving energy utilization rate, and rational utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

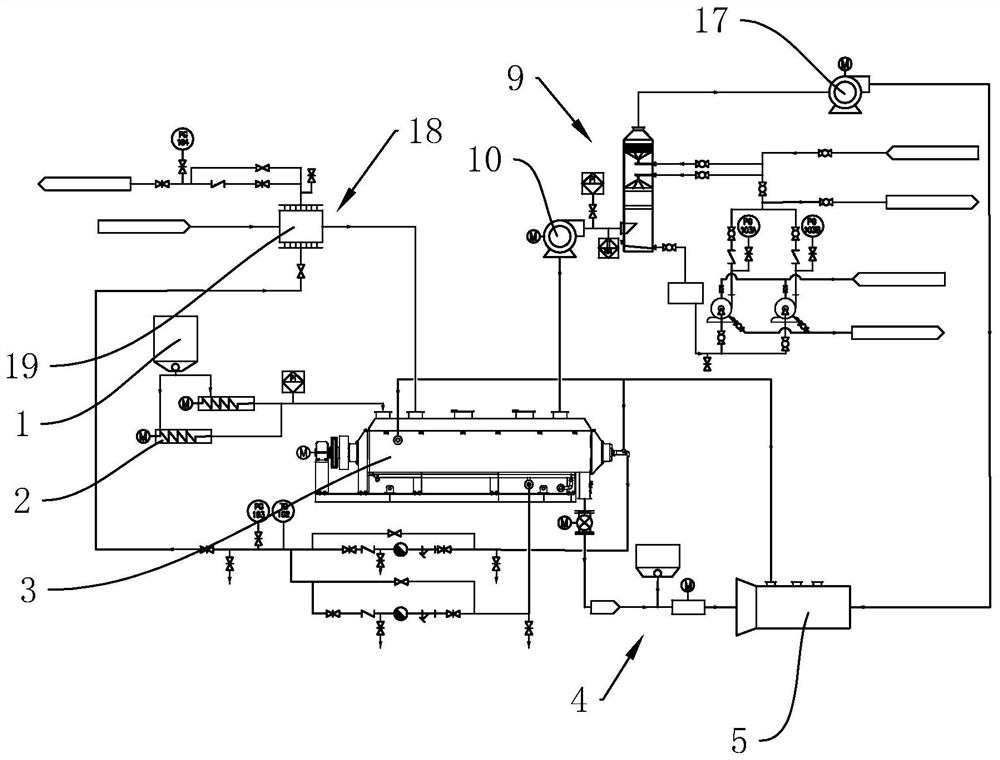

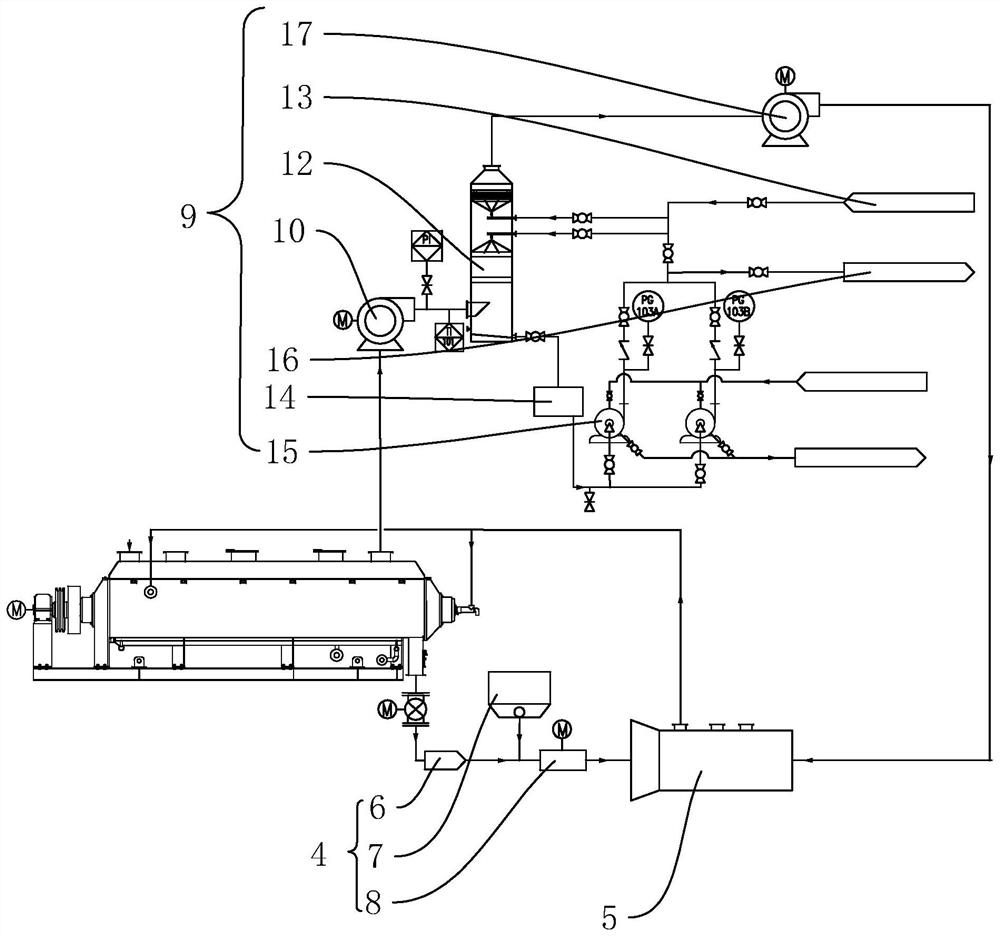

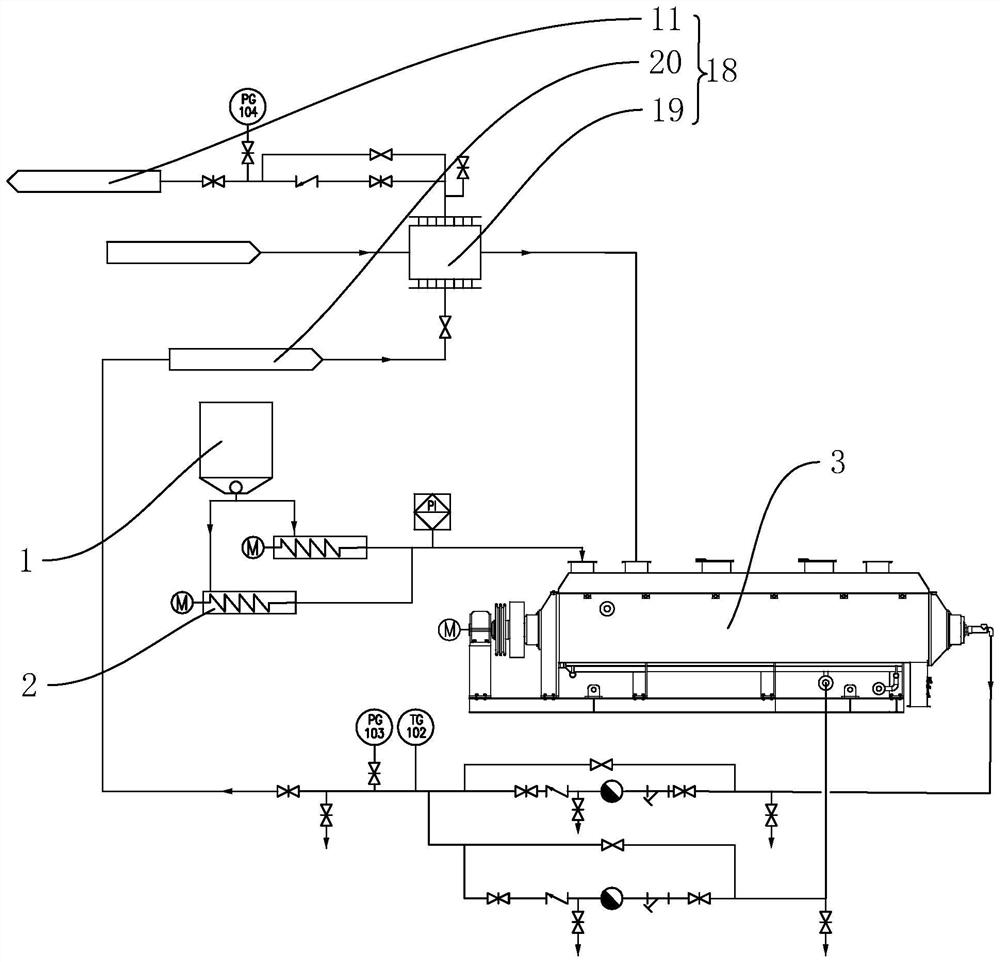

[0034] The following is attached Figure 1-3 The application is described in further detail.

[0035] The embodiment of the present application discloses a sludge drying and reuse system. refer to figure 1The sludge drying and reuse system includes a sludge wet silo 1. The upper end of the sludge wet silo 1 is open and used to fill the purified sludge. First, the sludge with a water content of 80% produced by the sewage station and The sludge with a water content of 90% produced by the reclaimed water recovery device is mixed and treated, and the mixed purified sludge is subjected to anaerobic treatment, so that the organic matter in the purified sludge is decomposed into combustion-supporting gases such as methane, carbon monoxide, and hydrogen sulfide. The discharge port at the lower end of the wet silo 1 is connected to a screw feeder, and the discharge port of the screw feeder is connected to a sludge pump 2. The sludge pump 2 can be selected as a sludge screw pump, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com