Super-infiltration metal net film and preparation method and application thereof

A super-wetting, omentum technology, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve the problem of long-term oil pollution prevention of super-hydrophilic underwater oleophobic omentum, affecting omentum separation efficiency and flux , short service life and other problems, to achieve the effect of enhancing long-term pollution resistance, long-term anti-pollution characteristics, and improving durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

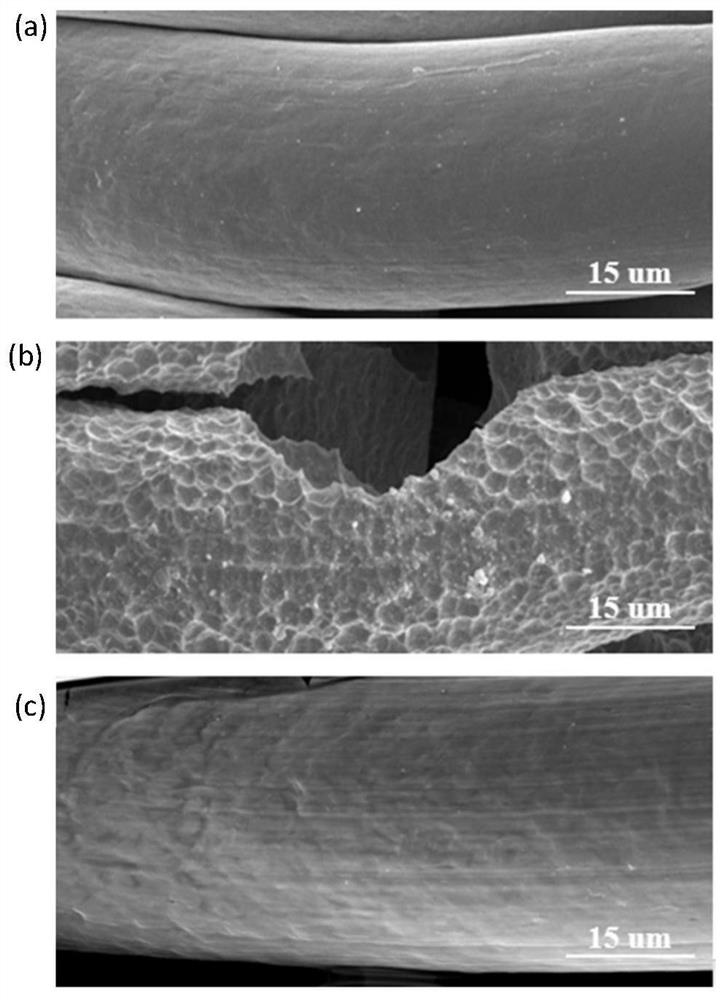

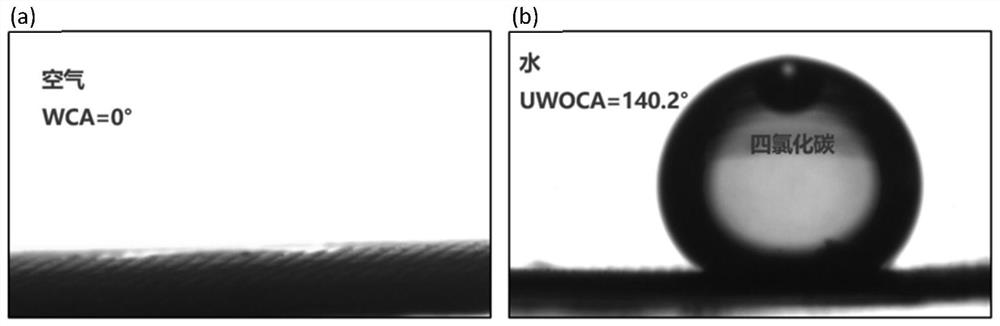

[0032] Embodiment 1 (morphology / flatness / separation efficiency)

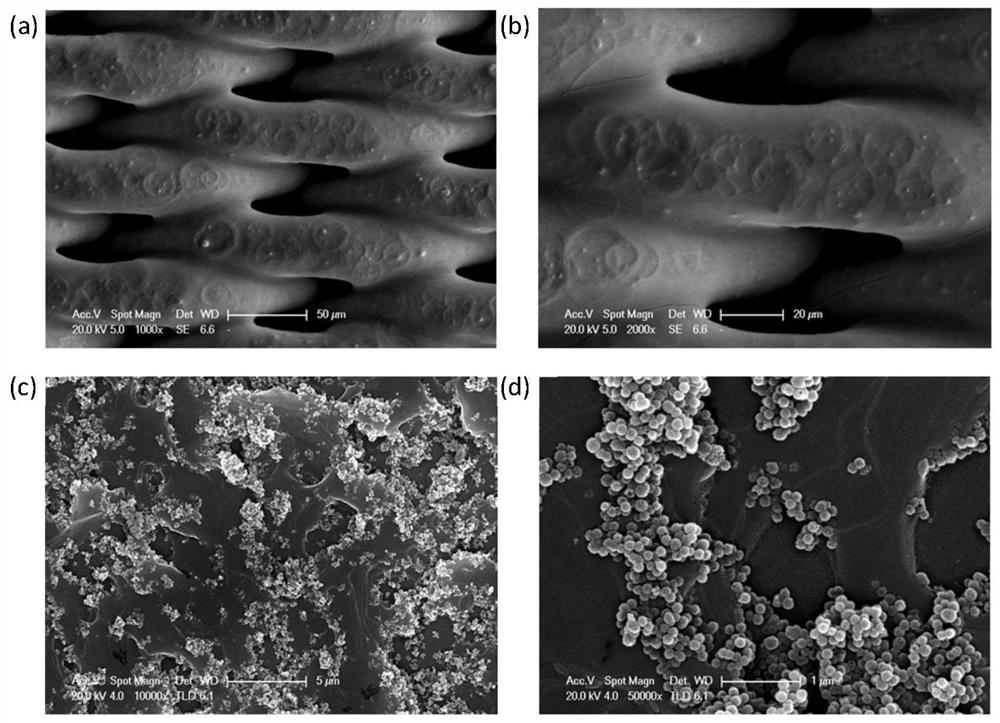

[0033] The 316 stainless steel wire mesh with a mesh size of 15 μm was dried for 10 minutes in absolute ethanol and 10 minutes in deionized water in a water bath at 40°C. Mix 5g of water-based acrylic resin, 1g of water-based epoxy resin and 2g of phytic acid aqueous solution evenly, then add it to 80g of deionized water, stir magnetically for 30min to make it evenly dispersed, then add 80g of chain-type nano-silica sol and 100g of nanocrystalline fiber to it The mixed powder of plain element and microcrystalline cellulose, magnetic force stirs 10min, then adds the aforementioned hollow silicon dioxide suspension of surfactant of 10g load and magnetic force stirs 10min, obtains superhydrophilic coating, it is sprayed on aforementioned stainless steel wire mesh, room temperature Leave for 1 hour to dry and solidify naturally to obtain a super-hydrophilic stainless steel omentum. The omentum is processed into a s...

Embodiment 2

[0034] Embodiment 2 (adding phytic acid for comparison)

[0035] The 316 stainless steel wire mesh with a mesh size of 15 μm was dried for 10 minutes in absolute ethanol and 10 minutes in deionized water in a water bath at 40°C. Mix 7g of water-based acrylic resin, 1.5g of water-based epoxy resin and 3g of phytic acid aqueous solution and add them into 100g of deionized water, stir magnetically for 30min to make them evenly dispersed, then add 85g of chain-type nano-silica sol and 100g of nanocrystalline The mixed powder of cellulose and microcrystalline cellulose was magnetically stirred for 10min, then the hollow silicon dioxide suspension of the aforementioned surfactant loading of 15g was added and magnetically stirred for 10min to obtain a superhydrophilic coating, which was sprayed on the aforementioned stainless steel wire mesh, Leave it at room temperature for 1 hour to dry and solidify naturally to obtain a super-hydrophilic stainless steel omentum. Rub the omentum w...

Embodiment 3

[0036] Embodiment 3 (macro oil pollution resistance)

[0037] The 316 stainless steel wire mesh with a mesh size of 9 μm was dried for 10 minutes in absolute ethanol and 10 minutes in deionized water in a water bath at 40°C. Mix 3g of water-based acrylic resin, 1g of water-based epoxy resin, 1g of water-based epoxy varnish, and 2g of phytic acid aqueous solution, and then add it to 100g of deionized water, stir magnetically for 30 minutes to make it evenly dispersed, and then add 110g of chain nano silicon The mixed powder of sol and 115g nanocrystalline cellulose and microcrystalline cellulose was magnetically stirred for 10min, then 12g of the aforementioned hollow silica suspension loaded with surfactant was added, and magnetically stirred for 10min to obtain a superhydrophilic coating, which was sprayed Place on the aforementioned stainless steel mesh at room temperature for 1 hour to dry and solidify naturally to obtain a super-hydrophilic stainless steel mesh. The oment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oil-water separation efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com