Method for preparing biodiesel from waste oil

A waste oil and biodiesel technology, applied in the field of oleochemical industry, can solve the problems of high organic content in glycerol esterification wastewater, difficulty in separating biodiesel and glycerin, and reduce the yield of biodiesel and glycerin, so as to avoid the generation of solid waste , Reduce the generation of saponified matter, the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

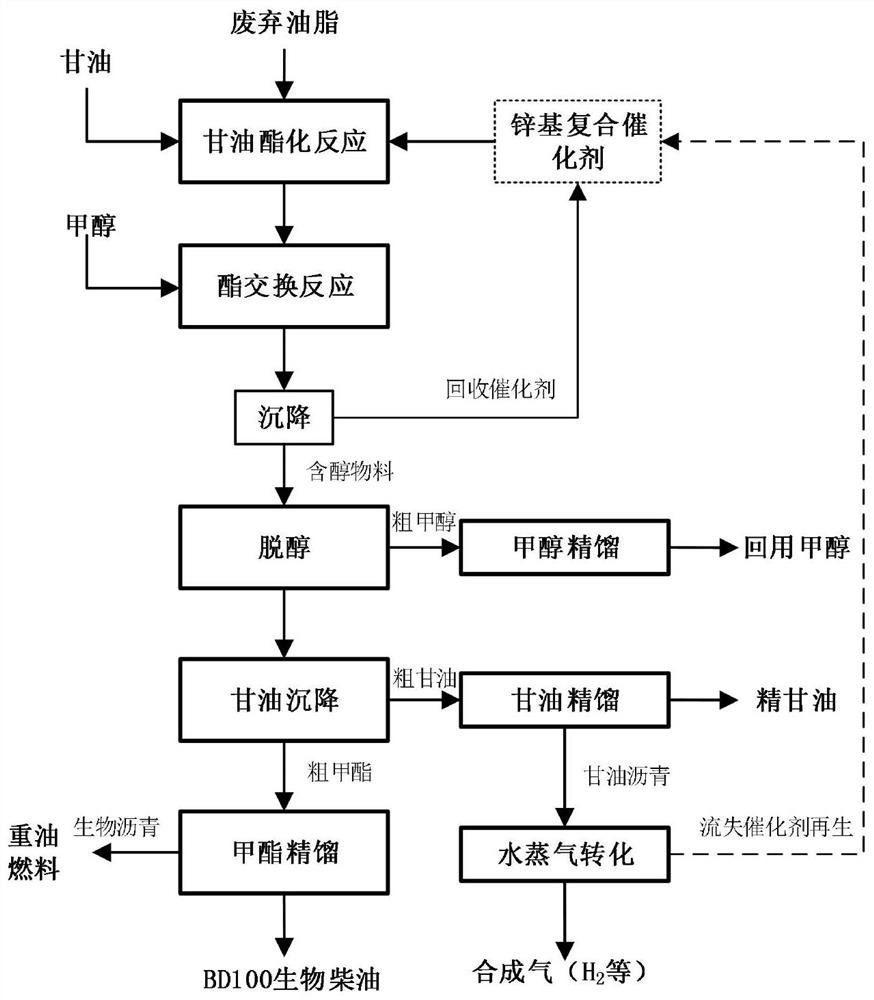

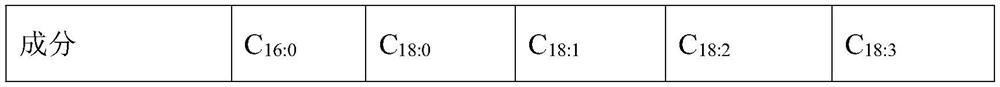

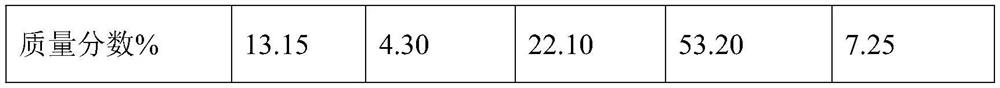

[0024] The biodiesel raw material used in Example 1 is acidified soybean oil (acid value 70 mgKOH / g), and the content distribution of fatty acid methyl esters is shown in Table 1.

[0025] Table 1. Contents of fatty acid methyl esters in biodiesel prepared from acidified soybean oil

[0026]

[0027]

[0028] The preparation process of the zinc oxide composite catalyst used in the present embodiment 1 is as follows:

[0029] The mass of raw material zinc oxide is 7.8g, oleic acid is 380g, and glycerin mass is 161g (the molar ratio of glycerol to fatty acid is 1.3:1). After mixing, react at a temperature of 150°C for 2 hours. After the reaction, 10.2g of zinc oxide composite is obtained by filtration. Catalyst (wet weight) for biodiesel production from acidified soybean oil.

[0030] The technical process of preparing biodiesel in this embodiment is as follows: figure 1 As shown, the process for preparing biodiesel includes the following processes:

[0031] 1) Glycerol...

Embodiment 2

[0044] The biodiesel raw material used in Example 2 is palmitic acid oil (acid value 110mgKOH / g), and its fatty acid methyl ester content distribution is shown in Table 4.

[0045] Table 4. Contents of each fatty acid methyl ester in biodiesel prepared from palmitic acid oil

[0046] Element C 12:0

C 14:0

C 16:0

C 18:0

C 18:1

C 18:2

mass fraction% 0.20 1.15 43.10 4.50 39.55 11.5

[0047] The preparation process of the zinc oxide composite catalyst used in present embodiment 2 is as follows:

[0048] The mass of raw material zinc oxide is 3.8g, lauric acid is 150g, and glycerin mass is 82.8g (the molar ratio of glycerol to fatty acid is 1.2:1). After mixing, react at a temperature of 170°C for 2 hours. After the reaction, 5g of zinc oxide compound is obtained by filtration. Catalyst (wet weight) for the production of biodiesel from palmitated oil.

[0049] The technical process of preparing biodiesel in this embodiment is as fo...

Embodiment 3

[0064] The biodiesel raw material used in Example 3 is palmitic acid oil (acid value 133mgKOH / g), and its content distribution of fatty acid methyl ester is shown in Table 7.

[0065] Table 7. Contents of each fatty acid methyl ester in biodiesel prepared from palmitic acid oil

[0066] Element C 12:0

C 14:0

C 16:0

C 18:0

C 18:1

C 18:2

mass fraction% 0.15 1.08 41.03 5.10 43.35 9.29

[0067] The preparation process of the zinc acetate composite catalyst used in present embodiment 3 is as follows:

[0068] The quality of raw material solid zinc acetate is 2.6g, oleic acid 200g, glycerin quality is 120g (glycerol and fatty acid molar ratio is 1.85:1), after mixing, it is reacted at 190 DEG C for 2h, obtains 5g zinc acetate composite catalyst through filtration (wet Weight), for the preparation of biodiesel from palmitated oil (AV=133mgKOH / g).

[0069] The technical process of preparing biodiesel in this embodiment is as follows: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com