Selenium-rich lithium selenium battery based on three-dimensional ordered porous carbon optical crystal and preparation method of selenium-rich lithium selenium battery

A three-dimensional ordered, porous carbon technology, used in lithium batteries, electrolyte battery manufacturing, battery electrodes, etc., can solve problems such as cracks and poor order of photonic crystals, and achieve the effects of simple process, improved electrical conductivity, and extended cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A method for preparing a selenium-rich lithium-selenium battery based on a three-dimensional ordered porous carbon crystal, characterized in that the method comprises the following steps:

[0044] (1) Preparation of selenium-enriched sulfur selenide

[0045] (1.1) Mix selenium powder and a small amount of sulfur powder according to the mass ratio of sulfur powder: selenium powder 0.05-0.2: 0.95-0.8, grind, seal in a glass tube, and then heat-treat in a tube furnace at 220°C-280°C for 1h -12h.

[0046] (2) Preparation of microsphere photonic crystals

[0047] (2.1) Disperse silicon oxide microspheres of a certain size into a solvent, ultrasonicate for a certain period of time, and prepare a solution with a mass concentration of 0.1%-10%; the particle size of the monodisperse microspheres in the solution is 100nm-1000nm;

[0048] (2.2) Pour the microsphere solution into a container for vacuum filtration, and filter for 10min-2h to prepare microsphere photonic crystals w...

Embodiment 1

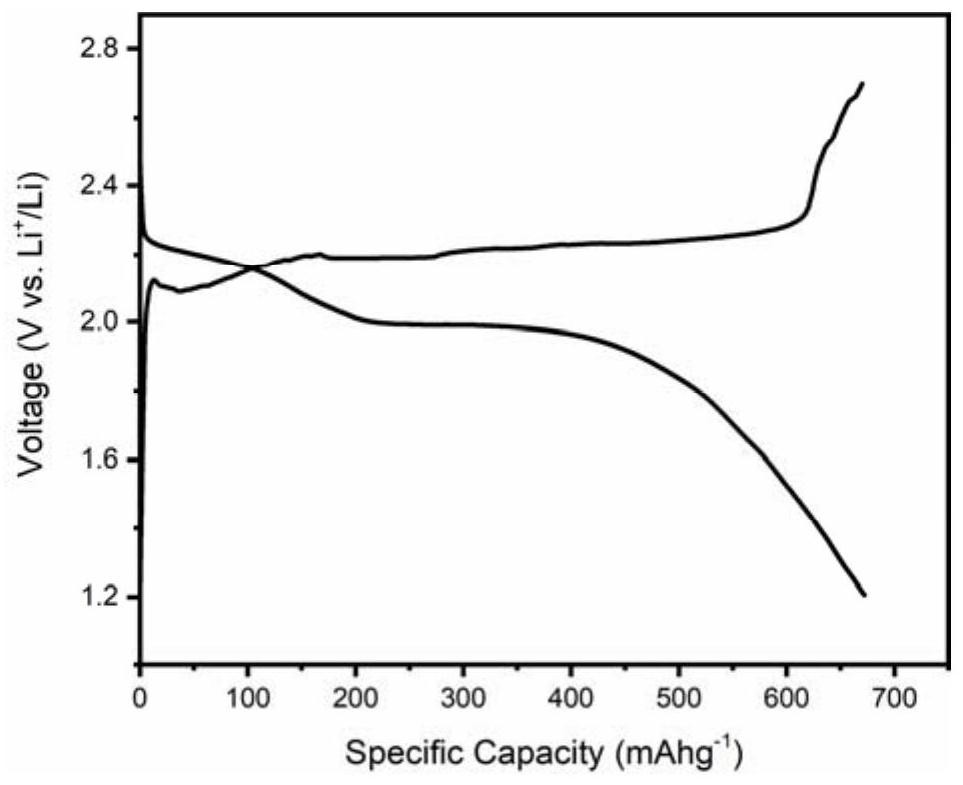

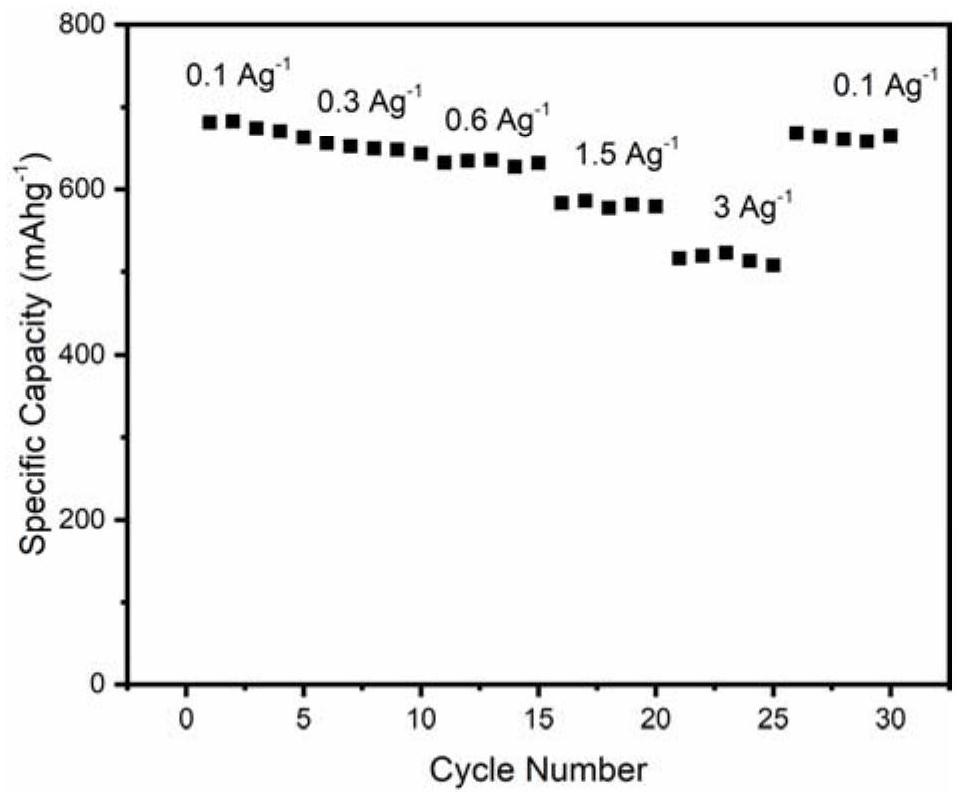

[0060] Sulfur powder and selenium powder with a molar mass ratio of 10% and 90% were mixed and ground, sealed in a glass tube, and then transferred to a tube furnace for 3 hours at 260°C to obtain selenium-enriched sulfoselenide. Add the silicon dioxide microsphere alcohol solution with a mass concentration of 2% and a diameter of 200 nm into a suction filter bottle, and perform vacuum filtration for 30 minutes to obtain microsphere photonic crystals with a certain thickness. To prepare metal framework organic precursor, mix 0.84g zinc nitrate hexahydrate, 0.96g 2-methylimidazole, 25mL methanol and 25mL N,N-dimethylformamide and stir for 10min. The microsphere photonic crystals were removed from the filter paper, immersed in the metal frame organic compound precursor solution for 1 h, and then moved to a dry oven at 70°C for 6 h to form a composite of silicon dioxide and metal frame organic compounds. The composite was moved to a tube furnace for heat treatment at 800°C for 3h...

Embodiment 2

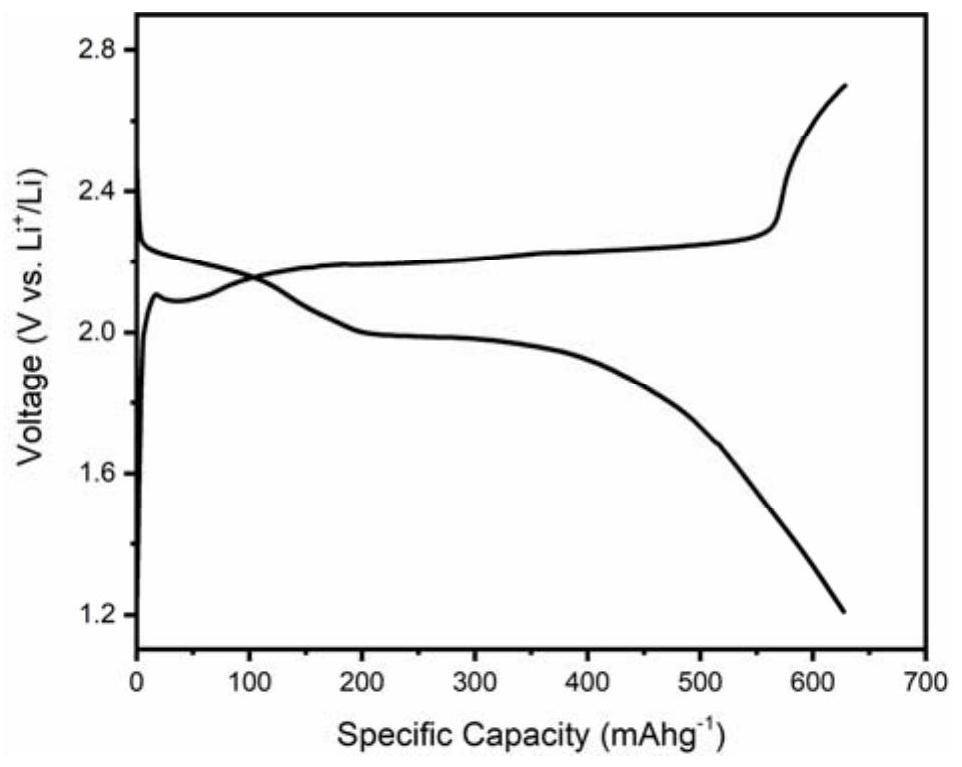

[0064] Sulfur powder and selenium powder with a molar mass ratio of 5% and 95% were mixed and ground, sealed in a glass tube, and then transferred to a tube furnace for 3 hours at 270°C to obtain selenium-enriched sulfoselenide. Add the silicon dioxide microsphere alcohol solution with a mass concentration of 0.5% and a diameter of 300 nm into a suction filter bottle, and perform vacuum filtration for 60 minutes to obtain microsphere photonic crystals with a certain thickness. To prepare metal framework organic precursor, mix 0.84g zinc nitrate hexahydrate, 0.96g 2-methylimidazole, 25mL methanol and 25mL N,N-dimethylformamide and stir for 10min. The microsphere photonic crystals were removed from the filter paper, immersed in the metal frame organic compound precursor solution for 1 h, and then moved to a dry oven at 90 ° C for 3 h to form a composite of silicon dioxide and metal frame organic compounds. The composite was transferred to a tube furnace for heat treatment at 900...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com