Silicon carbide composite substrate for preparing nitride single crystal film

A technology of silicon carbide substrate and composite substrate, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc. Thin and other problems, to shorten the production cycle, improve quality, reduce the effect of scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] First, the silicon carbide substrate is plasma cleaned. A mixture of hydrogen and nitrogen is introduced into the cleaning chamber, the flow ratio of hydrogen and nitrogen is 3:1; the microwave power is 800w; the cleaning temperature is 1000°C; the cleaning time is 60 minutes.

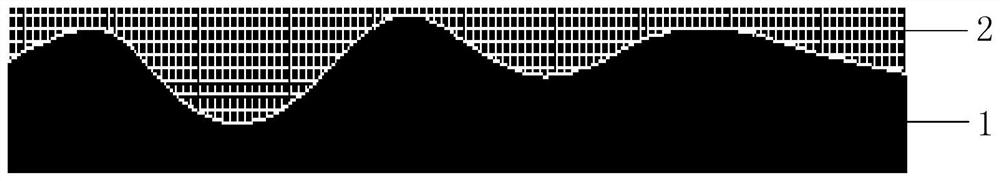

[0038] Put the cleaned silicon carbide substrate on the lifting platform in the reaction chamber, and adjust the height of the lifting platform so that the distance between the highest point on the upper surface of the silicon carbide substrate and the top wall of the reaction chamber is 5 μm. Then, evacuate to a pressure of 1*10 in the reaction chamber -6 After Pa, feed SiO gas and N at a flow ratio of 3:2 2 , when p(O 2 ) / pθ=10 -19 , p(SiO) / pθ=6.0*10 1.0 , that is, when the SiO partial pressure p(SiO)=6.0MPa (where p(O 2 ) is the partial pressure of oxygen, pθ is the standard atmospheric pressure), stop feeding SiO gas and nitrogen, and then heat the silicon carbide substrate to 2000°C to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com