Catalyst, preparation method thereof and method for reducing aldehyde content in polyether polyol

A technology of polyether polyols and polyether polyols, applied in the direction of heterogeneous catalyst chemical elements, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as bad odor and poor removal effect, and achieve high Effects of molecular weight, low aldehyde content, and low odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]Put 60 mL of 1.2M aqueous sodium bicarbonate solution into flask A as an aqueous solution. Add 241.6g of copper nitrate, 297.49g of zinc nitrate, 375.13g of aluminum nitrate and 89g of manganese nitrate into 240mL of ethylene glycol in flask B (the molar ratio of copper, zinc, aluminum, and manganese is 3:3:1:0.5 ). Stir flask B while heating at about 69°C, and slowly add the solution in flask A to flask B with a syringe pump at a rate of 8 mL / min for about 13 minutes. After the mixing is complete, the stirring is continued for 2 hours and the heating is about 70°C. Subsequently, the precipitate formed in bottle B was washed using a vacuum filter and washed 3 times with 300 ml of triple distilled water to dry the precipitate at 105 °C for 48 hr. The obtained powder was sintered in a muffle furnace at 350° C. for 3 hours, and the powder was chipped. The size of the catalyst chip was 3 mm×3 mm to obtain the final catalyst product.

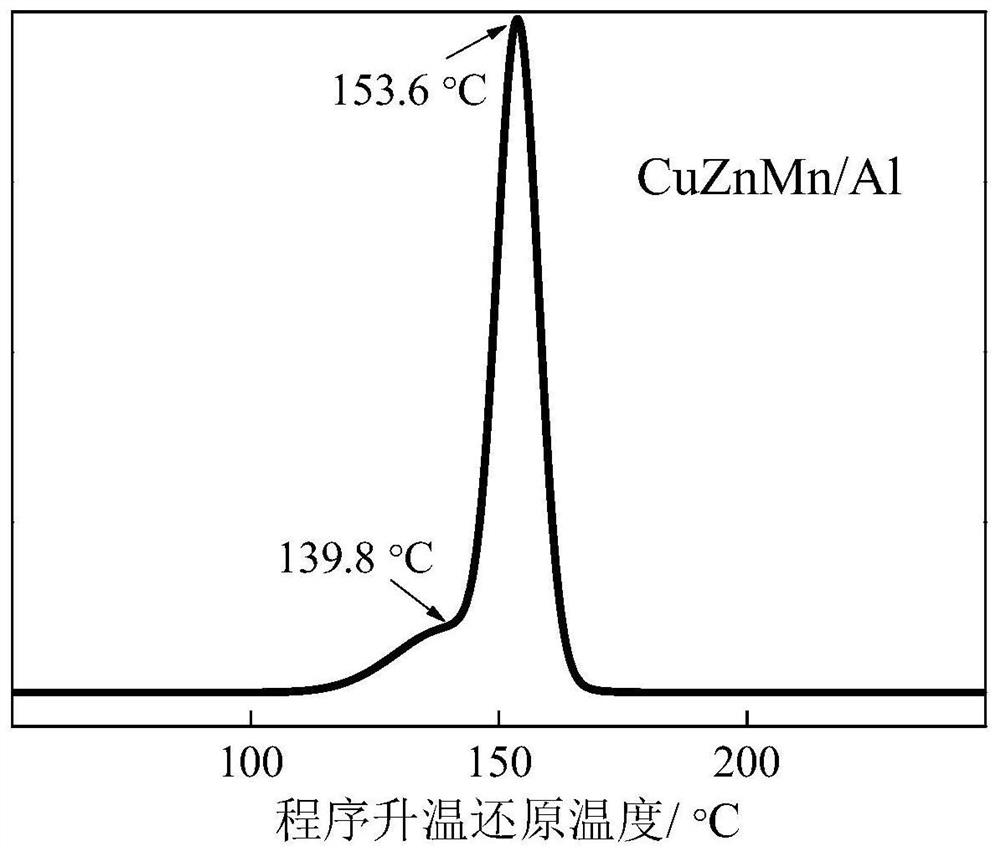

[0043] The temperature-programmed red...

Embodiment 2

[0045] According to the method of Example 1, the difference is that the molar ratio of copper, zinc, aluminum and manganese is 3:3:1:0.2 to finally obtain the final catalyst product. And the temperature-programmed reduction temperature of the catalyst was measured to be 150°C.

Embodiment 3

[0047] According to the method of Example 1, the difference is that the molar ratio of copper, zinc and aluminum is 3:3:1, (does not contain manganese). Finally, the final catalyst product is obtained. The temperature-programmed reduction temperature of the catalyst is 144°C

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com