Intelligent refrigeration artificial leather and preparation method thereof

A kind of artificial leather and intelligent technology, which is applied in the field of intelligent refrigeration artificial leather and its preparation, can solve the problems of intelligent refrigeration and insufficient comfort, achieve excellent radiation cooling effect, control the overall temperature, and have a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

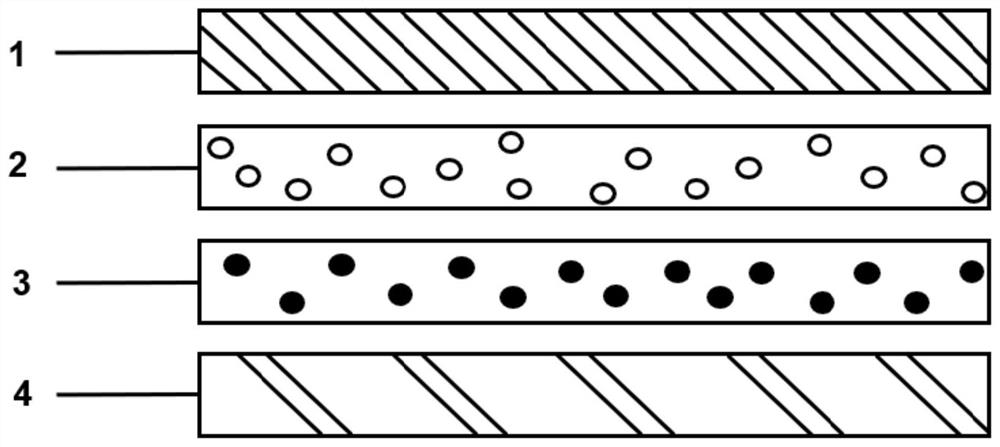

[0112] The present application also provides a method for preparing intelligent refrigeration artificial leather, which is characterized in that it comprises the following steps:

[0113] (1) After mixing the micro-nano particles and the polymer base material, the base layer is obtained through spinning and weaving;

[0114] (2) forming a refrigeration layer obtained by mixing polymer base materials and micro-nano particles on the base layer;

[0115] (3) mixing the polymer base material and the porogen, coating it on the cooling layer, removing the porogen, and forming a thermal insulation layer;

[0116] (4) Forming a surface layer comprising a polymer base material on the heat insulating layer to obtain an intelligent refrigeration artificial leather.

[0117] In a specific embodiment, the intelligent refrigerated artificial leather can be prepared by a direct coating method, and the method includes the following steps:

[0118] (1) Mix micro-nano particles and polymer su...

Embodiment 1

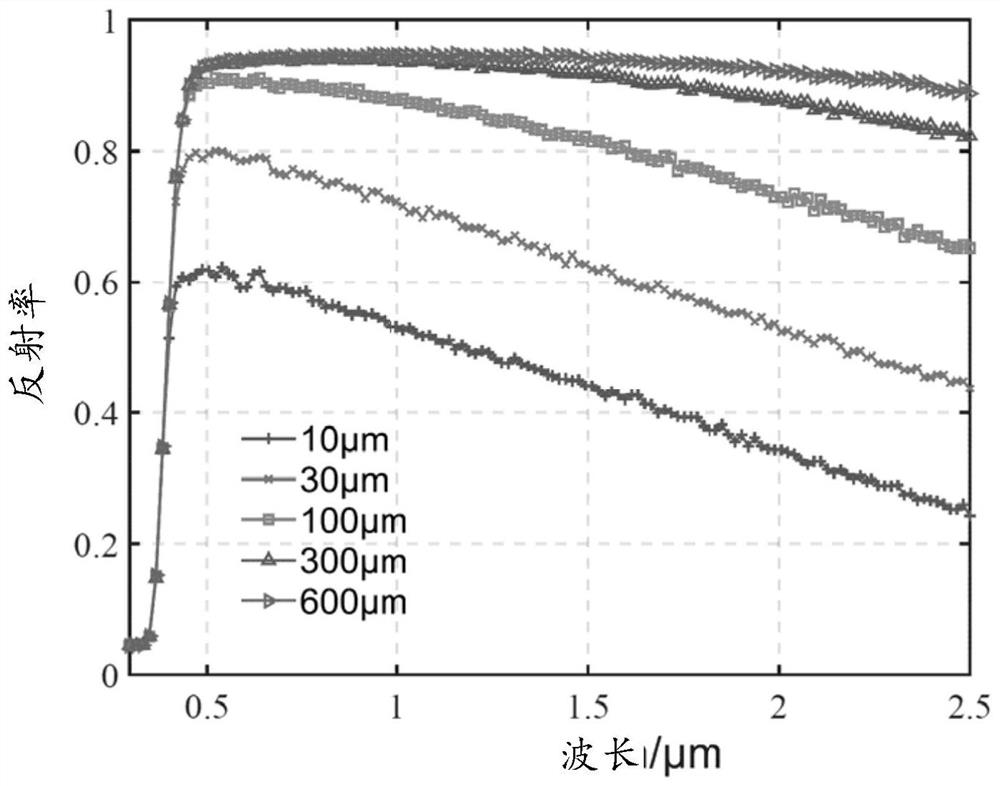

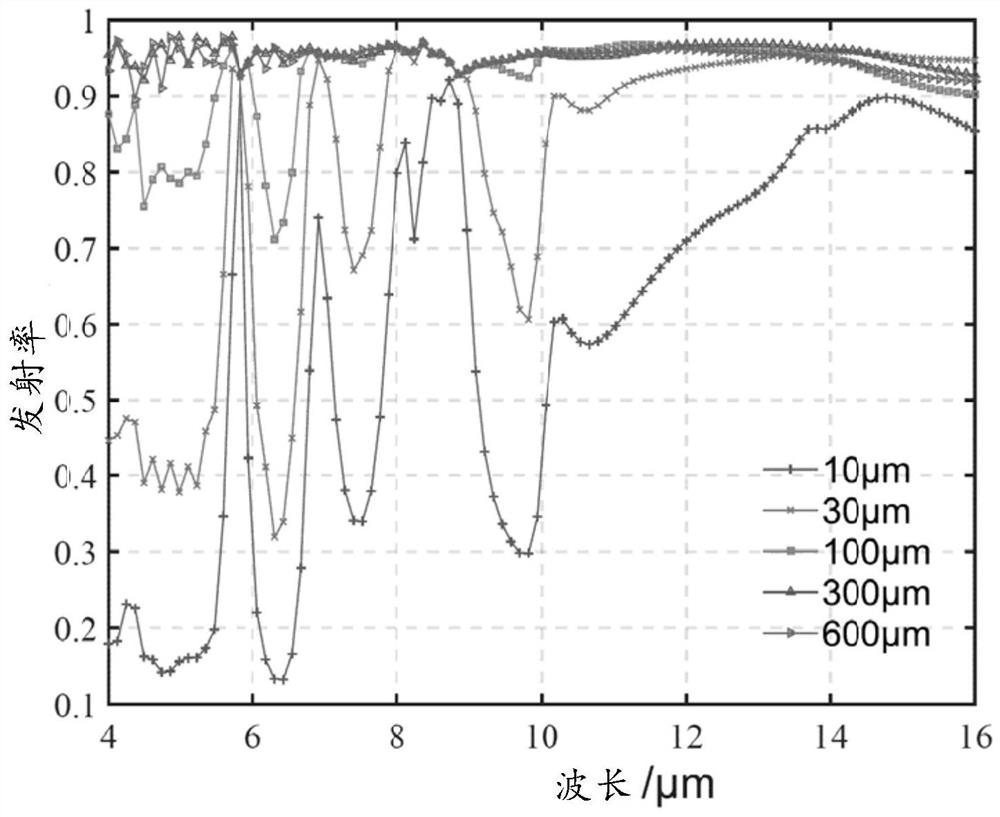

[0160] Using FDTD Soultions to build a simulation model of the refrigeration layer of intelligent refrigeration artificial leather, select PMMA as the polymer substrate, TiO 2 Micro-nano particles, the particle size of the micro-nano particles is 550±50nm, and the simulation effect diagram of the cooling layer with different thicknesses is obtained. Such as figure 2 As shown, the solar radiation reflectivity increases with the thickness of the cooling layer, and then gradually tends to saturation, and can achieve a solar radiation reflection effect higher than 90%. Such as image 3 As shown, in the wavelength range of 4 μm-16 μm, the infrared emissivity increases with the thickness of the cooling layer, and then gradually tends to saturation, and an infrared radiation effect higher than 90% can be achieved. Such as Figure 4 As shown, the radiative cooling effect of cooling layers with different thicknesses increases with the thickness of the cooling layer within 24 hours....

Embodiment 2

[0162] Prepare the intelligent refrigeration artificial leather of the present embodiment according to the following method:

[0163] (1) 300g of TiO with a particle size of 550nm 2 Granules and 700g PMMA are mixed, and after spinning, composite fibers are obtained, and the composite fibers are woven into non-woven fabrics as the base layer;

[0164] (2) 700g PVC, 420g particle size is 550nm TiO 2 Granules, 210g of dioctyl phthalate (DOP), 20g of zinc stearate, and 50g of calcium carbonate are mixed evenly to obtain a coating agent for the cooling layer, and then the non-woven fabric of the base layer is unwound. The cooling layer coating agent is coated on the non-woven fabric, and after plasticizing, a cooling layer is formed on the base layer;

[0165] (3) After mixing 700gPE, 210g dioctyl phthalate (DOP), 20g zinc stearate and 50g micron wood powder, apply it on the top of the cooling layer, and then remove the micron wood powder by water, That is, a thermal insulation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com