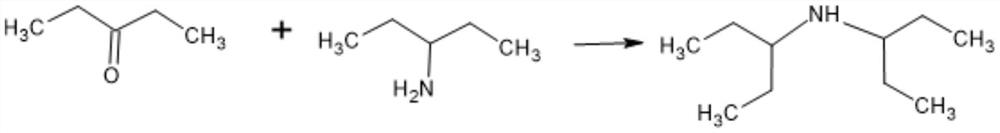

N-bis (1-ethyl-propyl)-3-pentylamine and preparation method thereof

A technology of pentylamine and ethyl, which is applied in the field of N-bis-3-pentylamine and its preparation, can solve the problems of troublesome post-processing, slow reaction speed, and many reaction steps, etc., and achieve simple post-processing and reduce synthesis Cost, the effect of simplifying the reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Add 10g of 3-pentanamine and 30mL of 3-pentanone (3-pentanone as a solution) into the autoclave, add 2g of p-toluenesulfonic acid and 2g of Pb / C, replace with nitrogen for 3 times, replace with hydrogen for 3 times, keep 0.8MPa Press for 20 minutes, turn on the stirrer, slowly raise the temperature to 80°C, control the pressure to 1.2MPa, GC sampling and analysis, if the raw material 3-amylamine ≤ 1%, stop the reaction, stop the introduction of hydrogen, cool down to 40°C, release the pressure, and then Nitrogen was replaced 3 times, the reaction liquid was heated and filtered, and the filtrate was distilled under reduced pressure in a rectification device to obtain 16.5 g of the product with a content of 99.1% and a yield of 91.5%.

Embodiment 2

[0039] Add 50g of 3-pentanamine and 150mL of 3-pentanone (3-pentanone as a solution) into the autoclave, add 2g of p-toluenesulfonic acid and 2g of Pb / C, replace with nitrogen for 3 times, replace with hydrogen for 3 times, keep 0.8MPa Press for 20 minutes, turn on the stirrer, slowly raise the temperature to 80°C, control the pressure at 1.2MPa, keep the temperature for 5 hours, and conduct sampling analysis by GC. If the raw material 3-amylamine ≤ 1%, stop the reaction, stop the hydrogen supply, and cool down to 40°C. The pressure was released, and then replaced with nitrogen for 3 times, the reaction liquid was heated and filtered, and the filtrate was distilled under reduced pressure in a rectification device to obtain 83.1 g of the product with a content of 99.0% and a yield of 92.0%.

Embodiment 3

[0041] Add 600g of 3-pentanamine and 1800mL of 3-pentanone (3-pentanone as a solution) into the autoclave, add 10g of p-toluenesulfonic acid and 10g of Pb / C, replace with nitrogen 3 times, replace with hydrogen 3 times, keep 0.8MPa Press for 20 minutes, turn on the stirrer, slowly raise the temperature to 80°C, control the pressure to 1.2MPa, react for 5h, GC sampling analysis, if the raw material 3-amylamine ≤ 1%, stop the reaction, stop the hydrogen supply, cool down to 40°C, and release pressure, then replaced with nitrogen for 3 times, the reaction solution was heated and filtered, and the filtrate was distilled under reduced pressure in a rectification device to obtain 994.5 g of the product, with a GC normalized content of 99.0% and a yield of 91.8%.

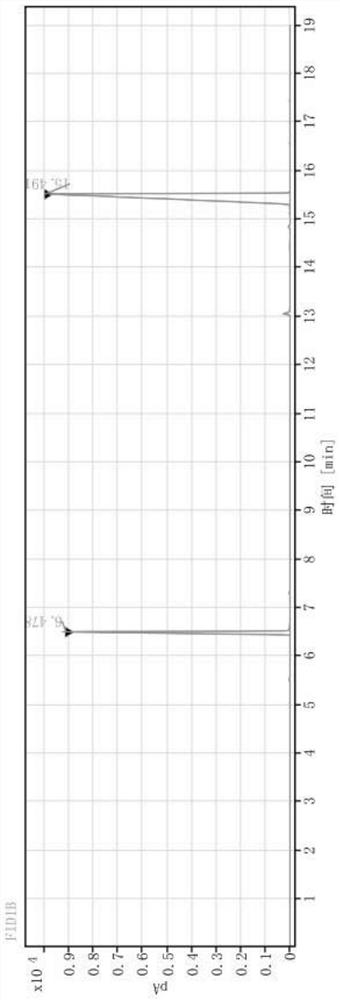

[0042] Analysis example

[0043] For gas chromatography analysis, a GC column equipped with HP-5 manufactured by Agilent Corporation and a 7820A GC analysis device manufactured by Agilent Corporation were used. For temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com