Production and manufacturing method of chloroethylene carbonate

A technology of chloroethylene carbonate and its manufacturing method, which is applied in the direction of hypochlorous acid, hypochlorite, chemical instruments and methods, etc., and can solve the limitation of storage conditions of chloroethylene carbonate and the fluctuation of the yield of chloroethylene carbonate , Sulfur dioxide gas is difficult to handle and other problems, to achieve the effect of improving thermal stability and storage stability at room temperature, improving purity, and reducing the formation of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

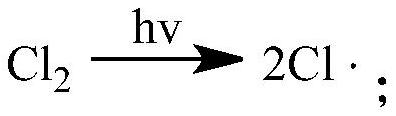

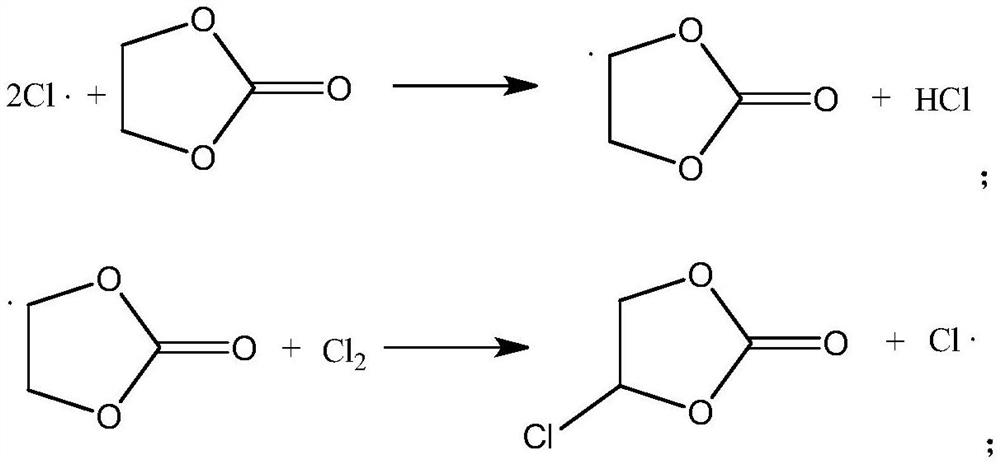

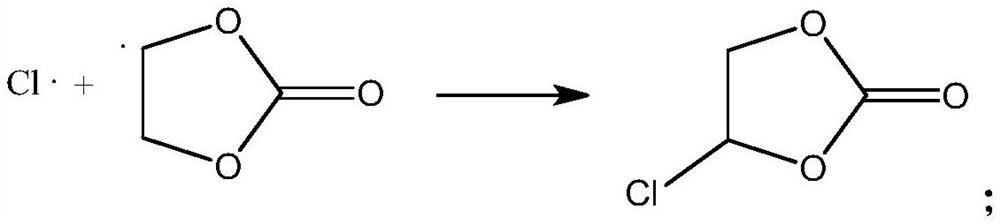

Method used

Image

Examples

Embodiment 1

[0021] A kind of production method of chloroethylene carbonate, comprises the following steps:

[0022] S1. Add process water required for absorption to the hydrochloric acid absorption system, start the absorption circulation pump, open the cooling water valve of the absorption cooler, and make the hydrochloric acid absorption system operate normally;

[0023] S2. Add liquid alkali required for absorption to the liquid alkali absorption system, start the absorption circulation pump, open the cooling water valve of the absorption cooler, and make the liquid alkali absorption system operate normally;

[0024] S3. Preheat ethylene carbonate at 40°C to obtain molten ethylene carbonate, start the feeding pump, pump 2000g of molten ethylene carbonate raw material into the reactor, and stop the feeding pump after the pumping is completed , the system is returned to normal pressure by introducing nitrogen gas;

[0025] S4. Open the nitrogen valve, fill the sleeve of the ultraviolet ...

Embodiment 2

[0043] When the product chloroethylene carbonate is stored, it is found that the product is stored for too long or heated, which will lead to a decrease in purity and affect its performance. For this problem, design and develop a kind of composite stabilizer for chloroethylene carbonate on the basis of embodiment 1, concrete manufacturing process is as follows:

[0044] A kind of production method of chloroethylene carbonate, comprises the following steps:

[0045]S1. Add process water required for absorption to the hydrochloric acid absorption system, start the absorption circulation pump, open the cooling water valve of the absorption cooler, and make the hydrochloric acid absorption system operate normally;

[0046] S2. Add liquid alkali required for absorption to the liquid alkali absorption system, start the absorption circulation pump, open the cooling water valve of the absorption cooler, and make the liquid alkali absorption system operate normally;

[0047] S3. Prehe...

Embodiment 3

[0057] Compared with Example 2, this embodiment has changed the feeding ratio of chlorine and nitrogen, the time interval of sampling analysis, the composition of the composite stabilizer and the addition amount of the composite stabilizer in the product, and all the other operations are unchanged, as follows:

[0058] A kind of production method of chloroethylene carbonate, comprises the following steps:

[0059] S1. Add process water required for absorption to the hydrochloric acid absorption system, start the absorption circulation pump, open the cooling water valve of the absorption cooler, and make the hydrochloric acid absorption system operate normally;

[0060] S2. Add liquid alkali required for absorption to the liquid alkali absorption system, start the absorption circulation pump, open the cooling water valve of the absorption cooler, and make the liquid alkali absorption system operate normally;

[0061] S3. Preheat ethylene carbonate at 40°C to obtain molten ethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com