Monoclinic crystal system crystal form substance and preparation method thereof

A technology of monoclinic crystal system and crystal form, which is applied in the field of monoclinic crystal system crystal form and its preparation, and can solve the problems of slow temperature rise, high red phosphorus vapor pressure, slow sample speed and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

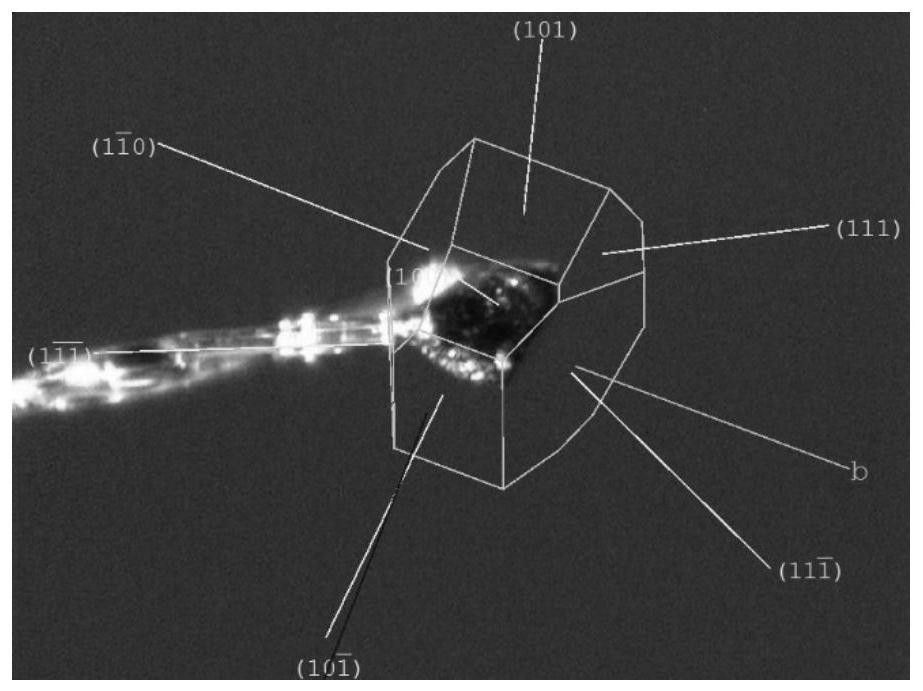

[0033]The second aspect of the present invention provides a method for preparing the monoclinic crystal form described in the first aspect of the present invention, the method comprising the following steps:

[0034] 1) Compressing elemental molybdenum and red phosphorus into tablets and wrapping hexagonal boron nitride to prepare inclusions;

[0035] 2) reacting the inclusions described in step 1) at 900-1100° C. under a pressure of 4-6 GPa to obtain a monoclinic crystal form.

[0036] In the method for synthesizing monoclinic crystals provided by the present invention, the step 1) is to compress elemental molybdenum and red phosphorus into tablets and then wrap hexagonal boron nitride to prepare inclusions. Among them, elemental molybdenum and red phosphorus need to be limited in a suitable ratio range. The molar ratio of elemental molybdenum to red phosphorus is 1:2.5-3.5. In one embodiment, the molar ratio of the elemental molybdenum to red phosphorus is 1:2.5-3; or 1:3-...

Embodiment 1

[0049] 1) Preparation of cylindrical reactants of molybdenum and red phosphorus under normal pressure

[0050] Mix chemically pure elemental molybdenum and red phosphorus in a molar ratio of 1:2.5 in a glove box, and mortar them in an agate mortar for half an hour. The reactant powder was compressed into a cylinder with a diameter of 3.5 mm and a height of 3.2 mm by a powder tablet press (pressure: 5 MPa). Because red phosphorus reacts with noble metal Pt under high temperature and high pressure, different from the sample wrapped with noble metal in the existing high temperature and high pressure experiment, the sample reactant in the present invention is wrapped with high temperature and high pressure resistant and chemically stable hexagonal boron nitride, Reduce the chance of generating impurity.

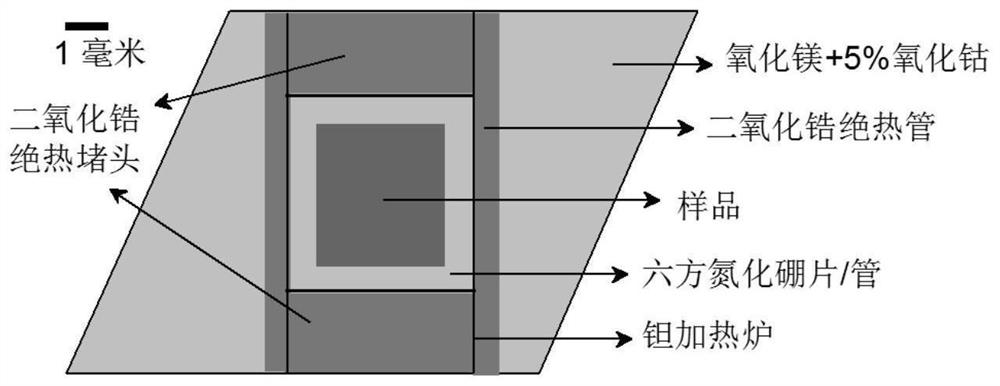

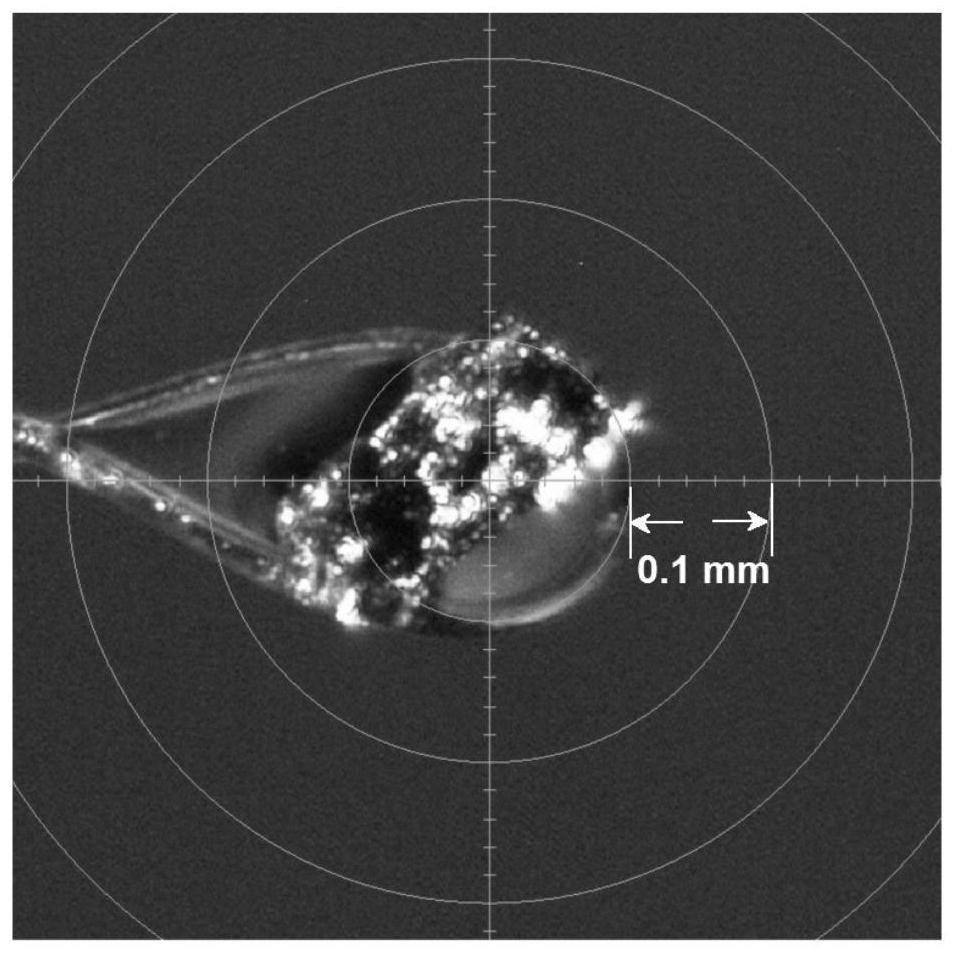

[0051] 2) Put the above sample and the hexagonal boron nitride protective sheath together into a tantalum heating furnace. Then put the sample into the high-pressure assembly f...

Embodiment 2

[0054] 1) Preparation of cylindrical reactants of molybdenum and red phosphorus under normal pressure

[0055] Chemically pure elemental molybdenum and red phosphorus were mixed uniformly in a glove box at a molar ratio of 1:3, and ground in an agate mortar for half an hour. The molybdenum phosphorus powder was compressed into a cylinder with a diameter of 3.5 mm and a height of 3.2 mm with a powder tablet press. The initial reactant of the cylindrical sample is protected by a hexagonal boron nitride tube and a disc to reduce the probability of generating impurity phases.

[0056] 2) Put the above sample and the hexagonal boron nitride protective sheath together into a tantalum heating furnace. Then put the sample into a high-pressure assembly for high-pressure high-temperature synthesis. The sample synthesis is carried out on a 2,000-ton Kawai-type large-cavity press. First slowly increase the pressure to 6GPa at room temperature, then start the heating program to heat up t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com