Carbon dioxide-based ionic antibacterial polyurethane as well as preparation method and application thereof

A carbon dioxide and ionic technology, applied in the field of carbon dioxide-based ionic antibacterial polyurethane and its preparation, polyurethane, to achieve good biological antibacterial properties, simple preparation method, and good structural adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a carbon dioxide-based ionic antibacterial polyurethane, which is prepared through the following steps:

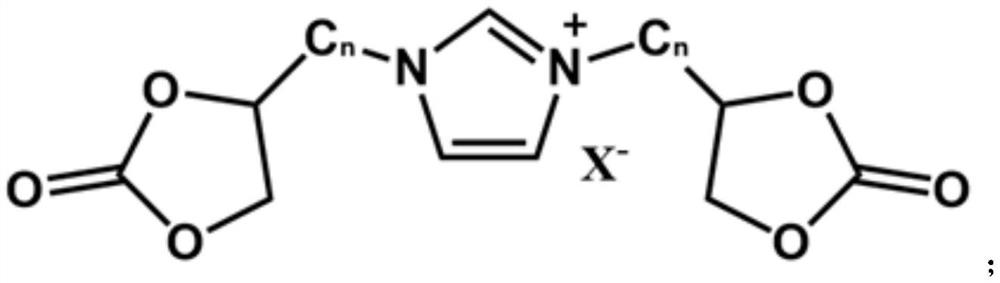

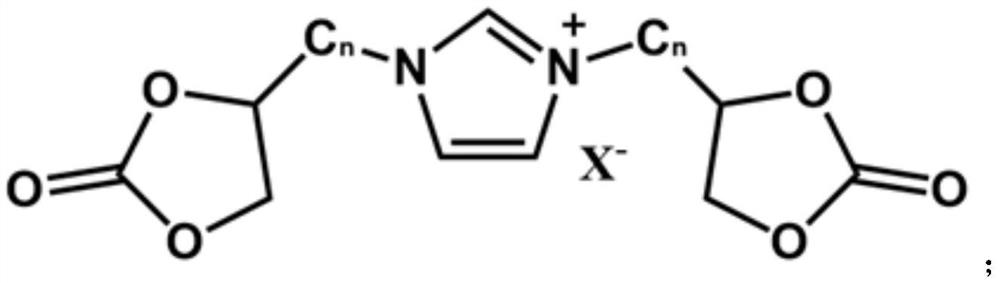

[0032] Dissolve 1 mmol CO in 10 mL DMSO 2 Derivatized ionic cyclic carbonate with imidazolium as cation and bromide as anion with addition of 1 mmol hexamethylenediamine and CO 2 Derivatized ionic cyclic carbonate 20 mol% DBU. The above precursor solution was poured into a round bottom flask, purged with nitrogen for 5 minutes to remove oxygen, then the temperature was raised to 80°C, stirred and reacted for 24 hours, washed with ethyl acetate for many times, precipitated and dried to obtain CO 2 Based on ionic polyurethane, the antibacterial rate against Staphylococcus aureus and Escherichia coli is over 99%.

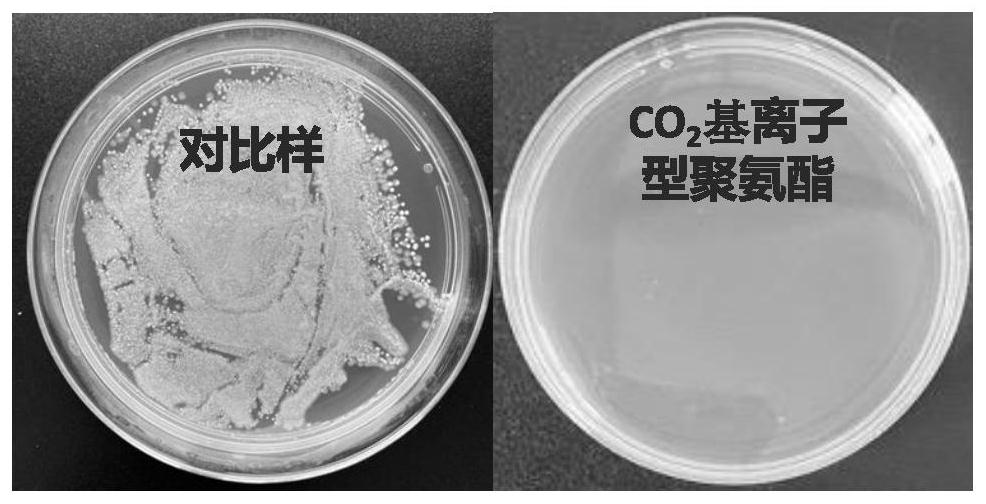

[0033] CO in this example 2 The antibacterial effect of base ionic polyurethane on Escherichia coli is as follows: figure 1 shown. The comparison sample is a blank sample.

Embodiment 2

[0035] This embodiment provides a carbon dioxide-based ionic antibacterial polyurethane, which is prepared through the following steps:

[0036] Dissolve 0.5 mmol CO in 10 mL DMSO 2 Derivatized ionic cyclic carbonate with imidazole as the cation and iodide as the anion with addition of 0.5 mmol hexamethylenediamine and CO 2 Derivatized ionic cyclic carbonate 20 mol% DBU. The above precursor solution was poured into a round bottom flask, purged with nitrogen for 5 minutes to remove oxygen, then the temperature was raised to 80°C, stirred and reacted for 24 hours, washed with ethyl acetate for many times, precipitated and dried to obtain CO 2 Based on ionic polyurethane, the antibacterial rate against Staphylococcus aureus and Escherichia coli is over 99%.

Embodiment 3

[0038] This embodiment provides a carbon dioxide-based ionic antibacterial polyurethane, which is prepared through the following steps:

[0039] Dissolve 1 mmol CO in 10 mL DMSO 2 Derivatized ionic cyclic carbonate with imidazolium as the cation and tetrafluoroborate ion as the anion with the addition of 1 mmol hexamethylenediamine and CO 2 Derivatized ionic cyclic carbonate 20 mol% DBU. The above precursor solution was poured into a round bottom flask, purged with nitrogen for 5 minutes to remove oxygen, then the temperature was raised to 100°C, stirred and reacted for 24 hours, washed with ethyl acetate for many times, precipitated and dried to obtain CO 2 Based on ionic polyurethane, the antibacterial rate against Staphylococcus aureus and Escherichia coli is over 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com