Negative electrode material and lithium ion battery containing same

A negative electrode material and negative electrode technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of slow bulk electron transport and increased side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] [Preparation method of negative electrode material]

[0069] The present invention also provides a method for preparing the above-mentioned negative electrode material, the method comprising the steps of:

[0070] (1) In an inert atmosphere, the graphite is ball milled to obtain the first intermediate product;

[0071] (2) In an inert atmosphere, the silicon oxide block is ball-milled to obtain a second intermediate product;

[0072] (3) dissolving the aromatic polymer into the solvent, and mixing uniformly to obtain the first mixture;

[0073] (4) mixing the first intermediate product, the second intermediate product and the first mixture to obtain a second mixture;

[0074] (5) drying the second mixture to obtain a third intermediate product;

[0075] (6) The third intermediate product is put into a high-speed fusion machine, fully fused to obtain the fourth intermediate product;

[0076] (7) Sintering the fourth intermediate product at high temperature in an iner...

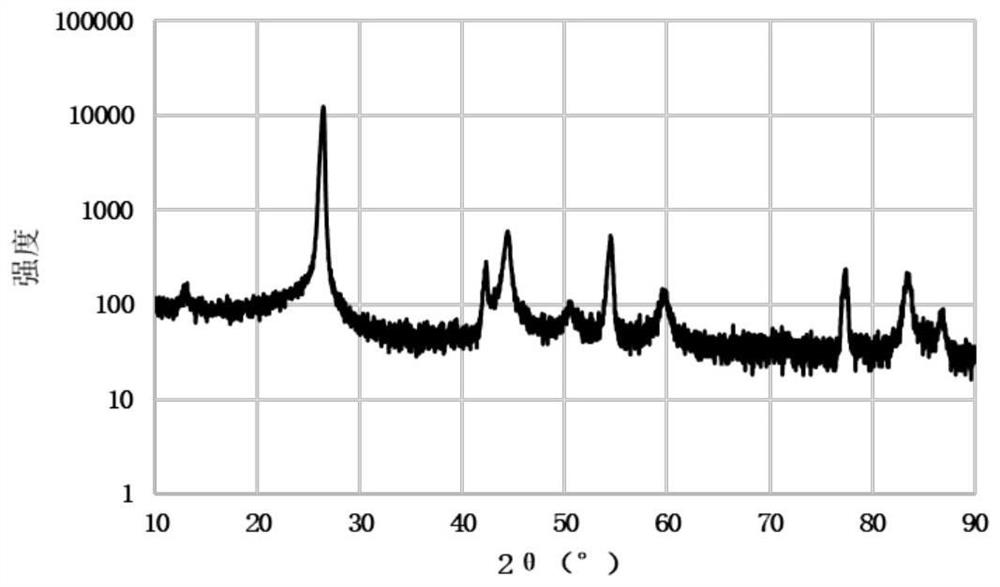

Embodiment 1~8

[0096] The preparation method, parameters and physical and chemical properties of the negative electrode material are exemplarily given below.

[0097] Embodiments 1-8 adopt the following steps to prepare the negative electrode material:

[0098] (1) Under an inert atmosphere, the graphite is ball-milled to obtain a first intermediate product.

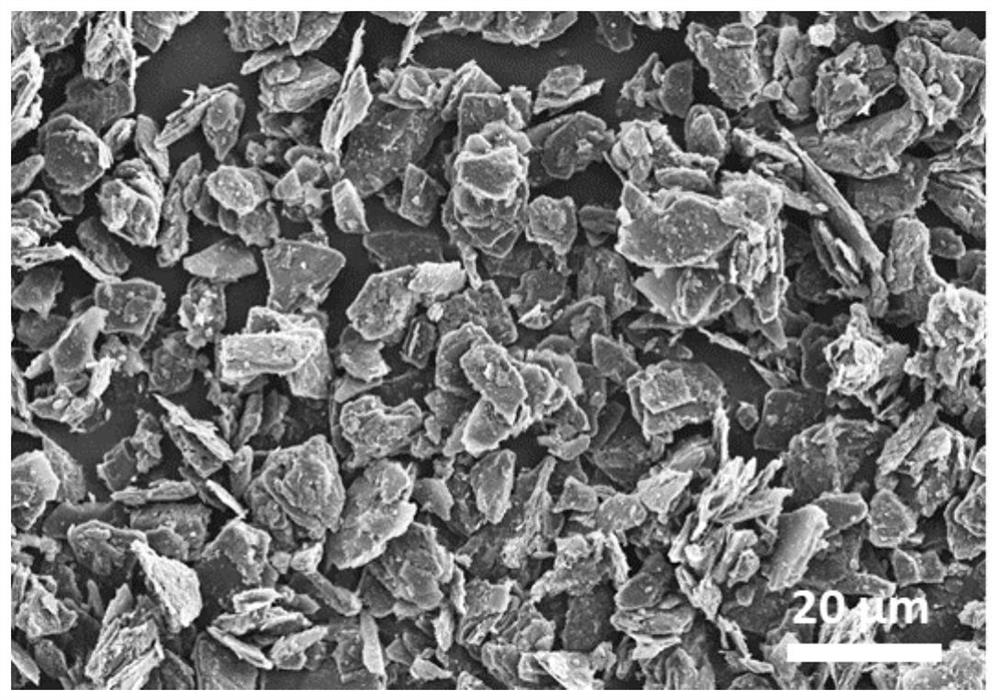

[0099] Described graphite is the artificial graphite that does not do coating treatment, obtains by commercial purchase, and its Dv50 is about 17.45 μ m, and BET is about 3.03m 2 / g, the Dv50 of the first intermediate product is about 11.8 μm.

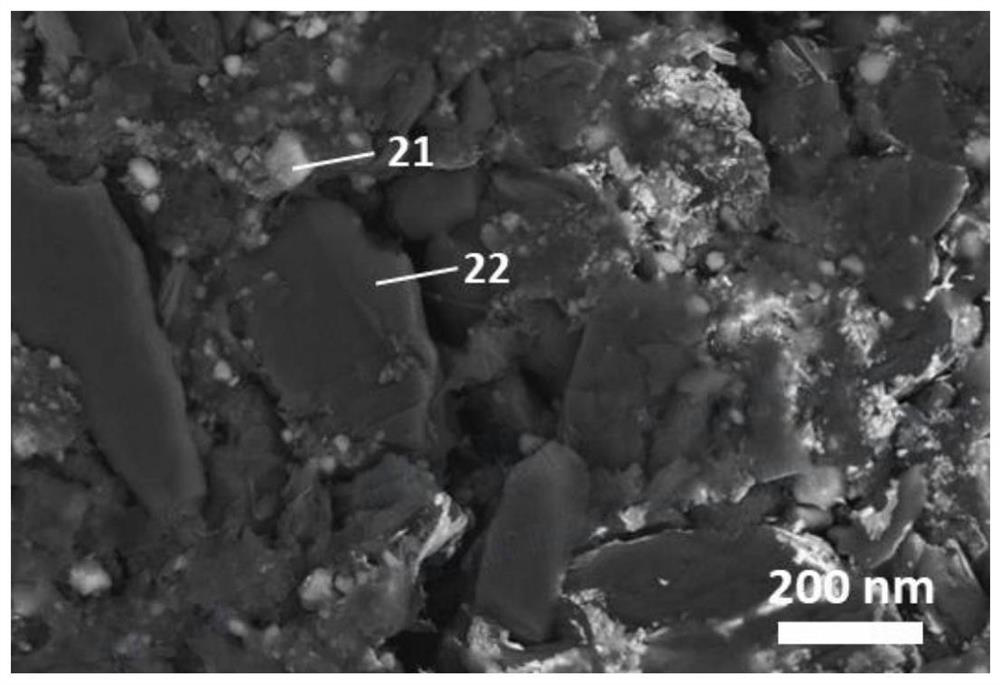

[0100] (2) Dilute silica powder and silicon powder by SiO 2 / Si mass ratio is 1.15 (corresponding to embodiment 1~4) or 3.38 (corresponding to embodiment 5~8) to mix, obtain mixture;

[0101] at 10 -5 Under the pressure of MPa and the temperature of 1150 ° C, the mixture was reacted for 6 hours to generate gas;

[0102] condensing the gas to obtain silicon oxide blocks;

[0103] In an ine...

Embodiment 9-18 and comparative example 6-10

[0160] The lithium ion batteries of Examples 9-16 and Comparative Examples 6-10 were prepared by using the negative electrode materials of Examples 1-8 and Comparative Examples 1-5, respectively.

[0161] The full battery production method is as follows:

[0162] The negative electrode materials, sodium carboxymethylcellulose, styrene-butadiene rubber, and Super P of Examples 1-8 and Comparative Examples 1-5 were mixed according to a mass ratio of 96.5:1.6:1.6:0.3, deionized water was added, and The negative electrode slurry is obtained under the action of a stirrer. The negative electrode slurry is evenly coated on a copper foil with a thickness of 8 μm, and the surface density of the negative electrode slurry coated on the surface of the negative electrode current collector is about 5.0 mg / cm 2 . The copper foil was transferred to an oven at 80° C. to dry for 12 hours, and then rolled and cut to obtain a negative electrode sheet.

[0163] Lithium cobaltate (LCO), polyviny...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com